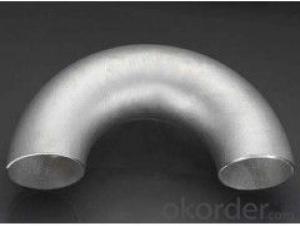

60 Degree Aluminium Elbow used on Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

60 degree aluminum elbow:

Material : carbon steel , stainless steel and alloy steel,

60 degree aluminum elbow

Specifications

ASTM B16.9 A234 WPB 90degree 1.5D carbon steel elbow

1.A234 WPB elbow

2.size:1/2"-72"

3.material:A234 WPB

4.API CE ISO

ASTM B16.9 A234 WPB 90degree 1.5D carbon steel elbow

1.A234 WPB elbow

2.size:1/2"-72"

3.material:A234 WPB

4.API CE ISO

Size | 1/2''-24 seamless elbow 26''-72''butt weld elbow |

Wall Thickness | SCH10-SCH160,STD,XS,XXS, GOST , DIN, JIS standard thickness |

Standard | ASTMA234,ASTM A420,ANSI B16.9/B16.28/B16.25,ASME B16.9, JIS B2311-1997/2312, JIS B2311/B2312, DIN 2605-1/2617/2615, GB 12459—99,GOST,EN Standard etc. |

Material | Q235, 20#, 10#, Q345 A234 WPB, WP5, WP9,WP11, ST37.0,ST35.8,ST37.2,ST35.4/8,ST42,ST45,ST52,ST52.4 STP G38,STP G42,STPT42,STB42,STS42,STPT49,STS49 |

Application | Low and middle pressure fluid pipeline,boiler, petroleum and natural gas industry,drilling,chemical industry, electric industry,shipbuilding, fertilizer equipment and pipeline, structure,petrochemical, pharmaceutical industry |

Surface | Sand blasting, black anti-rust oil or galvanized , 3PE,etc. |

Package | Seaworthy Package, Plastic film,Ptywood Wooden Cases or wooden pallet or |

Certificate | ISO9001:2008, CE, API , SGS,BV, etc |

Capacity | 50000tons/year |

Advantages | 1.Reasonable price with excellent quality 2.Abundant stock and prompt delivery 3.Rich supply and export experience, sincere service 4. Reliable forwarder, 2-hour away from port. |

- Q:How do aluminum profiles contribute to daylighting strategies?

- Aluminum profiles contribute to daylighting strategies by being used in the construction of windows, doors, and skylights. These profiles are designed to be lightweight, durable, and have excellent thermal properties. They allow for larger glass panels, maximizing the amount of natural light that enters a space. Additionally, the profiles can be customized to accommodate different glazing options, such as low-emissivity coatings or solar control films, which help regulate heat gain and loss. Overall, aluminum profiles enhance daylighting strategies by promoting the use of natural light, reducing reliance on artificial lighting, and improving energy efficiency in buildings.

- Q:How do aluminum profiles perform in thermal insulation applications?

- Aluminum profiles generally have poor thermal insulation properties compared to other materials. However, their performance can be enhanced by including thermal breaks or using aluminum profiles with built-in insulation, such as polyamide strips. Additionally, the use of double or triple glazing in combination with aluminum profiles can further improve thermal insulation in applications such as windows and doors.

- Q:How do aluminum profiles perform in terms of corrosion resistance?

- The outstanding corrosion resistance of aluminum profiles is well-known, attributed to the formation of a protective oxide layer on the surface. This oxide layer effectively shields against corrosion, even in challenging environments, acting as a barrier to halt further oxidation and corrosion. Moreover, the corrosion resistance of aluminum profiles can be further improved through diverse surface treatments like anodizing or powder coating, offering supplementary defense against corrosion. Consequently, aluminum profiles possess remarkable corrosion resistance, rendering them ideal for a vast array of applications in industries such as construction, transportation, and manufacturing.

- Q:Can aluminum profiles be used in retail store fixture manufacturing?

- Yes, aluminum profiles can be used in retail store fixture manufacturing. Aluminum profiles are versatile and lightweight, making them ideal for designing and constructing various fixtures such as display shelves, racks, signage, and framing systems. Additionally, aluminum profiles offer durability, corrosion resistance, and a sleek appearance, making them a popular choice for retail environments.

- Q:Can aluminum profiles be used in electrical switchgear manufacturing?

- Yes, aluminum profiles can be used in electrical switchgear manufacturing. Aluminum profiles are lightweight, yet strong and durable, making them an ideal choice for constructing switchgear cabinets. They offer excellent corrosion resistance, which is essential for protecting electrical components from moisture and other environmental factors. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, allowing for efficient and cost-effective manufacturing processes.

- Q:What are the design options for aluminum profiles?

- There are several design options available when it comes to aluminum profiles, allowing for a wide range of applications and customization possibilities. Here are some of the design options commonly used with aluminum profiles: 1. Extrusion Shapes: Aluminum profiles can be extruded into various shapes, such as square, rectangular, round, T-shaped, I-shaped, or custom profiles. This flexibility in shape allows designers to create profiles that perfectly match the requirements of their project. 2. Surface Finishes: Aluminum profiles can be finished with different surface treatments to enhance their appearance and protect them from corrosion. Some popular surface finishes include anodizing, powder coating, polishing, brushing, and laminating. These finishes can provide a variety of colors, textures, and levels of glossiness to match specific design preferences. 3. T-Slot Profiles: T-slot profiles are a type of aluminum extrusion that features a T-shaped slot on one or more sides. These profiles are commonly used in the construction of frameworks, machine guards, and other structures that require easy assembly and reconfiguration. The T-slot design allows for easy insertion and adjustment of connecting elements such as bolts, nuts, and brackets. 4. Thermal Break Profiles: Thermal break profiles are designed with a thermal barrier inserted between the interior and exterior parts of the profile. This design helps to minimize the transfer of heat or cold between the two sides, making them suitable for applications where thermal insulation is important, such as windows, doors, and curtain walls. 5. Customization: Aluminum profiles can be further customized through additional machining processes, such as cutting, drilling, tapping, milling, or bending. These processes allow for the creation of unique shapes, hole patterns, or features that meet specific design requirements. 6. Integration: Aluminum profiles can be designed to integrate with other components or systems, such as hinges, connectors, fasteners, or brackets. This integration capability provides flexibility in assembly and allows for the creation of complex structures or modular systems. Overall, the design options for aluminum profiles are vast, allowing for versatility, functionality, and aesthetic appeal. Designers can choose from a range of shapes, finishes, and additional features to create aluminum profiles that meet their specific project needs.

- Q:Can aluminum profiles be used in the construction of modular office spaces?

- Certainly, modular office spaces can undoubtedly utilize aluminum profiles in their construction. With their lightweight nature, durability, and exceptional structural integrity, aluminum profiles prove to be an excellent option for modular construction projects. They can be effortlessly fabricated and assembled to form a variety of components, including walls, partitions, doors, windows, and framing systems for modular office spaces. Furthermore, aluminum profiles offer immense design flexibility, enabling customization and adaptation to diverse office layouts and requirements. Moreover, they possess high resistance to corrosion, which proves particularly advantageous in office environments susceptible to moisture and humidity. In essence, aluminum profiles offer a multitude of benefits in terms of strength, versatility, and aesthetics, rendering them a favored choice for construction in modular office spaces.

- Q:Aluminum Alloy rail safety glass balcony design, Aluminum Alloy profiles for what is standard specifications?

- The main specifications of aluminum alloy doors and windows are: 35 series, 38 series, 40 series, 60 series, 70 series, 90 series, etc.. The so-called 35, 38...... Refers to the aluminum alloy profiles, the main frame width of 35 mm, 38 mm, respectively....... Sealed balcony usually adopts 70 series or 90 series, and if less than 70, the degree of firmness is difficult to guarantee.

- Q:How do aluminum profiles handle extreme weather conditions?

- Aluminum profiles are known for their excellent resistance to extreme weather conditions. Due to their inherent corrosion resistance, they can withstand exposure to rain, snow, UV radiation, and high temperatures without deteriorating or losing their structural integrity. Additionally, aluminum profiles have a low thermal expansion coefficient, making them highly stable and resistant to warping or cracking in extreme temperature fluctuations. Overall, aluminum profiles are a reliable choice for outdoor applications, as they can handle a wide range of weather conditions with minimal maintenance.

- Q:Tips for identifying aluminum profiles

- First of all, to see whether the aluminum profile has obvious distortion, the surface is smooth and smooth, there is no crack or boldness of vision, scratches, burrs, and if found, some super good, do not buy.Secondly, it is necessary to carefully check the color of aluminum surface, whether there are different shades of color, there is color difference, that is, the quality is not pass.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

60 Degree Aluminium Elbow used on Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords