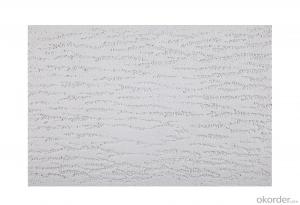

3TREES Texture Paint Texture Creator Emulsion Paint for Exterior Wall

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Compared to the stone and tile materials, the product not only provides the adornment effect, but greatly reduces the cost.

Application scope:

Cement, concrete, masonry, gypsum etc.

Packaging: 30kg, 80kg

Main components: Acrylic emulsion, natural siliceous sand.

Theoretical consumption: 1.4~4kg/㎡/coat (thickness of dry film: 2mm).

Dry time: Touch dry, 4H/25℃; Thorough dry,48H/25℃; Recoat time,2-6H based on temperature>5℃& humidity<85%.

Features: 1. Excellent environmental performance, odorless, weather shield 2. Water-repelling and air permeable performances 3. Able to conceal minor wall cracks and tears caused by regional mechanical and temperature changes 4. Various color and pattern options

Recommended application system: 1. Treated Concrete Wall 2. P0503 Anti-Cracking Rough Putty (1-2 coats) 3. Exterior Primer (1 coat) 4. A0003A Texture Paint (1-2 coats) 5. E0106 Waterborne Topcoat (1 coat)

|

- Q:Is the pigment poisonous? , I work in the paint line, every day is to do toner, what color has, all day there will be a lot of toner inhalation of the lungs, who can tell me that the toner is not poison ah?

- Toxic ingredients are the main ingredients containing lead, people involved in lead too much damage to the brain and kidney organs, can not be long engaged in this work, but also regularly check the body!

- Q:What is the difference between spraying and brushing?

- Painting. Paint the machine more expensive, the use of guns for construction, the effect of this construction process is that the wall surface smooth, feel good, fullness is good, called excellent. Paint with a fast construction, good flatness, no texture and other advantages. The disadvantage is that the paint loss is relatively large, late maintenance trouble, because the latter part of the repair, then the workers can not pull the machine over the paint, and brush out with the spray out of the texture is certainly different.

- Q:The name of all the blue series in the paint paint

- Sky blue pigment composition is cobalt stannate, is the green color of the blue, light and opaque, with a certain coverage, good light resistance, but the color strength in general;

- Q:What is the difference between Dorotheco soft lacquer and matte paint?

- The price is different. The finished product content is different. The general selection of paint can be seen when a small area of the effect. You can compare it in detail.

- Q:Polymer lithium battery and 18650, which is more expensive?

- 18650 is currently the highest level of Panasonic Sanyo 3200MAH, and do not believe what high-capacity high-density that are virtual standard, the capacity of the polymer according to the volume so there is a large capacity, the price is almost it, Sanyo 2600MAH price of 20 yuan, 2600 Of the polymer is almost the price, but the 18650 battery relative to the polymer in terms of slightly higher risk, mainly to see your battery reserved space for what battery put in

- Q:What is the difference between oily and waterproof latex paint?

- Oily paint is solvent-based paint, construction and drying process has a strong smell, VOC certainly more than GB domestic standards. Not recommended for use indoors, especially in confined spaces. Solvent-based products generally have a good anti-(splash) water function. But absolutely can not be used as a waterproof coating.

- Q:i could use details for swirl painting guitar from do you primer, what type of paint is used

- Swirl Painting

- Q:what is the difference between oil based paint and water based paint in terms of ingredients? Is there a certain material that oil based paint contains that water based paint doesn't? Does oil based paint actually contain oil or gas? Why is oil based paint thicker?All help is appreciated!

- Set-up your space and get your canvas and paints ready. But you must first have an idea of what subject-matter you want to undertake. I have a full-time job and a Rottweiler-of-an-ex-wife, while pursing an MSW. Painting just seem so out of perspective when dealing with every day drama--but, then when that brush hits that canvas it is so therapeutic. I dig man, I am in the same funk right now. Good luck!

- Q:Is the water-based dyes with pigments, or oily have dyes with pigments, or have ah, get me very confused

- Water is the dye oil is pigment

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

3TREES Texture Paint Texture Creator Emulsion Paint for Exterior Wall

- Loading Port:

- Xiamen

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords