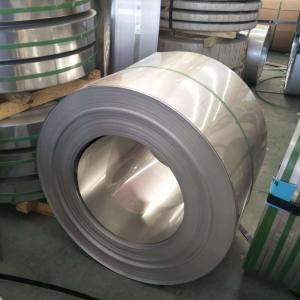

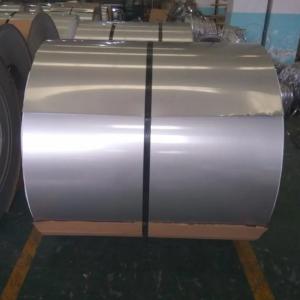

Stainless Steel Coils for Carbin Building Decoration JIS EN ASTM AISI

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

SGS

Thickness:

1

Width:

1000

Length:

2000

Net Weight:

19

Stainless steel which can be produced in different chemical, physical and mechanical properties, have high corrosion and heat resistance, mechanical strength, manufacturing ease, aesthetic appearance hygienic and long lasting properties.

STANDARDS

ASTM A240/A240M,ASME A240/A240,EN 10088-2, EN10028-7,JIS G 4305

| Hot Rolled Stainless Steel Coil | |

| Size | Thickness 2.8mm-14mm, Width can be customized |

| Grade | SUS 201, 202, 304L/H, 316L/H, 321/H, 317/H, 347/H, 310S, 430, 409/L, 31803, 32750, 32760, etc |

| Standard | JIS,EN,ASTM,AISI |

| Finish | 1D, No.1 finish, black finish |

| Cold Rolled Stainless Steel Coil | |

| Size | Thickness 0.02mm-3mm, Width can be customized |

| Grade | SUS 201, 202, 304L/H, 316L/H, 321/H, 317/H, 347/H, 310S, 430, 409/L, 31803, 32750, 32760, etc |

| Standard | JIS,EN,ASTM,AISI |

| Finish | 2B, 2D, BA, NO.3, NO.4, SB, NO.8, HL |

| Application | Elevator, Carbin Decoration, Building Decoration, Architectural Decoration, Kitchen Decoration |

- Q:What is the electrical resistance of stainless steel sheets?

- The electrical resistance of stainless steel sheets can vary depending on several factors, such as the grade of stainless steel, its thickness, and the specific properties of the alloy used. Generally, stainless steel exhibits a relatively high electrical resistance when compared to other metals. This is primarily due to its composition, which includes a significant amount of chromium and other alloying elements that impede the flow of electric current. However, the precise value of electrical resistance can range from a few micro-ohms per square meter to several ohms per square meter, depending on the specific grade and thickness of the stainless steel sheet. Consequently, it is essential to refer to the manufacturer's specifications or conduct specific electrical resistance tests to obtain accurate values for a particular stainless steel sheet.

- Q:What are the common types of corrosion that affect stainless steel sheets?

- There are several common types of corrosion that can affect stainless steel sheets. One of the most common types is known as pitting corrosion. Pitting corrosion occurs when localized areas of the stainless steel surface become damaged, resulting in small pits or holes. This type of corrosion is typically caused by exposure to chlorides, such as saltwater or certain chemicals. Another common type of corrosion is known as crevice corrosion. Crevice corrosion occurs in tight spaces or crevices where oxygen and other corrosive agents may become trapped. This can happen in areas where stainless steel sheets are joined or in areas where dirt, debris, or moisture can accumulate, creating an environment conducive to corrosion. Galvanic corrosion is another type that can affect stainless steel sheets. This occurs when stainless steel comes into contact with a dissimilar metal in the presence of an electrolyte, such as moisture. The difference in electrical potential between the two metals can result in a flow of electrical current, leading to corrosion of the stainless steel. Stress corrosion cracking is a type of corrosion that occurs under tensile stress, combined with exposure to a corrosive environment. This type of corrosion can cause cracking or fracturing of stainless steel sheets, compromising their structural integrity. Lastly, intergranular corrosion is a type of corrosion that occurs along the grain boundaries of stainless steel. This can result from improper welding practices, exposure to high temperatures, or chemical exposure. Intergranular corrosion can weaken the stainless steel sheets and make them more susceptible to other forms of corrosion. It is important to consider these common types of corrosion when working with stainless steel sheets, as they can impact the performance and durability of the material. Proper maintenance, regular inspections, and appropriate corrosion prevention measures can help mitigate the risk of corrosion and prolong the lifespan of stainless steel sheets.

- Q:What is the area of stainless steel plate?

- For example, a steel coil with known weight, thickness, length, width, and price, you can work out the cost price of each meter, and then you can set the price as you expect it

- Q:What welding equipment do we need for welding stainless steel sheet and stainless steel square tube?

- 1 argon arc welding machine! If the person who has not been married, as little as possible, that thing has radiation, long time use of physiology is influential. You know what you do.2, regardless of the front and back can be, as long as it looks beautiful and practical.3, welding technology is good, it will not be ugly after welding.4, only the use of technology to make up for the lack of machinery, and then cattle B hardware, there is no good software is not good.5, welding rod, protective mask and so on.

- Q:Can stainless steel sheets be used for outdoor railings?

- Yes, stainless steel sheets can be used for outdoor railings. Stainless steel is highly resistant to corrosion, making it an ideal material for outdoor applications. It can withstand exposure to various weather conditions, including rain, humidity, and sunlight, without rusting or deteriorating. Additionally, stainless steel's strength and durability ensure that it can withstand the pressure and weight typically exerted on railings, making it a reliable choice for outdoor installations.

- Q:What is the maximum thickness of a stainless steel sheet?

- The maximum thickness of a stainless steel sheet can vary depending on the specific grade or type of stainless steel being used. In general, stainless steel sheets can range from as thin as 0.4 millimeters (0.0157 inches) to as thick as 100 millimeters (3.937 inches) or more. However, it is important to note that the availability of thicker sheets may be limited and can vary based on the supplier or manufacturer. Additionally, some stainless steel alloys may have different thickness limits due to their composition and intended use. Therefore, it is always recommended to consult with a supplier or refer to the specifications provided by the manufacturer to determine the maximum thickness of the specific stainless steel sheet you require.

- Q:How do I prevent rusting on stainless steel sheets?

- To prevent rusting on stainless steel sheets, there are several steps you can take: 1. Keep the surface clean: Regularly clean the stainless steel sheets using a mild detergent or stainless steel cleaner. This will help remove any dirt, grime, or contaminants that could lead to corrosion. 2. Avoid abrasive cleaners: Avoid using harsh or abrasive cleaners, as they can scratch the surface of the stainless steel, making it more susceptible to rusting. Stick to non-abrasive cleaning solutions and soft cloths or sponges. 3. Remove rust promptly: If you notice any signs of rust on the stainless steel sheets, it is important to address it immediately. Use a stainless steel cleaner or a mixture of vinegar and water to gently remove the rust. Rinse thoroughly and dry the surface afterwards. 4. Protect against moisture: Stainless steel is resistant to rust, but it can still corrode in the presence of moisture. To prevent this, ensure that the stainless steel sheets are properly installed and sealed to protect against water or moisture infiltration. Avoid leaving standing water on the surface and promptly dry any spills or moisture. 5. Apply a protective coating: Consider applying a protective coating to the stainless steel sheets to provide an extra layer of protection against rust. There are various sealants and coatings available specifically designed for stainless steel that can help prevent corrosion. 6. Regular maintenance: Regularly inspect the stainless steel sheets for any signs of damage, rust, or corrosion. Address any issues promptly to prevent further damage. Additionally, perform routine cleaning and maintenance to keep the surface in optimal condition. By following these preventive measures, you can significantly reduce the chances of rusting on stainless steel sheets and maintain their longevity and aesthetic appeal.

- Q:Can stainless steel sheets be used for elevator cabs?

- Yes, stainless steel sheets can be used for elevator cabs. Stainless steel is a common material choice for elevator cabs due to its durability, aesthetic appeal, and resistance to corrosion. It provides a sleek and modern look while also being able to withstand the wear and tear of daily use in elevators.

- Q:How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, there are a few common methods you can consider: 1. Adhesive: Using a high-strength construction adhesive specifically designed for metal bonding, apply it to the backside of the stainless steel sheet. Press the sheet firmly against the wall and hold it in place until the adhesive cures. This method is suitable for smaller, lightweight stainless steel sheets. 2. Screw fasteners: Drill holes through the stainless steel sheet and into the wall at regular intervals. Use stainless steel screws that are appropriate for the thickness of the sheet and the wall material. Insert the screws into the holes and tighten them until the sheet is securely attached to the wall. This method works well for larger and heavier stainless steel sheets. 3. Magnetic mounting: If the stainless steel sheet is magnetizable, you can use magnets to attach it to a metal wall. Place strong magnets on the backside of the sheet, aligning them with the corresponding magnets on the wall. The magnets will hold the sheet in place, allowing for easy installation and removal. 4. Panel mounting systems: Some manufacturers offer panel mounting systems specifically designed for stainless steel sheets. These systems typically consist of brackets or clips that attach to the backside of the sheet and then hook onto a track or rail system mounted on the wall. This method provides a secure and visually appealing attachment solution. When attaching stainless steel sheets to a wall, it's important to ensure that the wall surface is clean, dry, and properly prepared. This will help optimize the adhesion and prevent any potential issues. Additionally, always follow the manufacturer's instructions and guidelines for the specific method or product you are using.

- Q:Can stainless steel sheets be used for elevator wall panels?

- Yes, stainless steel sheets can be used for elevator wall panels. Stainless steel is a popular choice for elevator interiors due to its durability, cleanliness, and aesthetic appeal. It offers a sleek and modern look that can enhance the overall appearance of the elevator. Moreover, stainless steel is resistant to corrosion, stains, and scratches, making it suitable for high-traffic areas like elevators. It is also easy to clean and maintain, ensuring that the elevator walls remain in good condition for a long time. Additionally, stainless steel sheets can be customized in various finishes, patterns, and colors to match the design requirements and preferences of the building or elevator. Overall, stainless steel sheets are an excellent choice for elevator wall panels.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coils for Carbin Building Decoration JIS EN ASTM AISI

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords