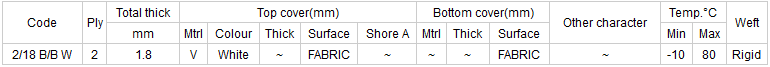

1.8mm Double Sided Polyester PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.8mm Double Sided Polyester PVC Conveyor Belt

PVC Conveyor Belt Features:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4.Color:Apple Green,Petrol Green,Blue,Black,etc

5. Various surfaces with high, medium and low coefficient friction

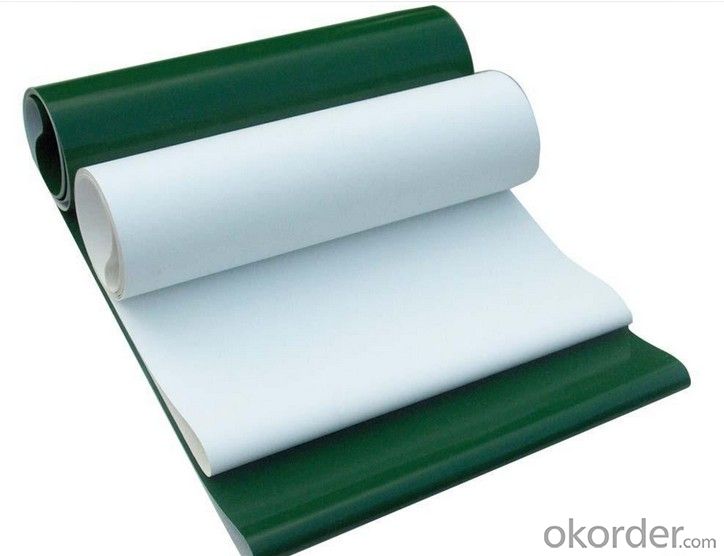

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

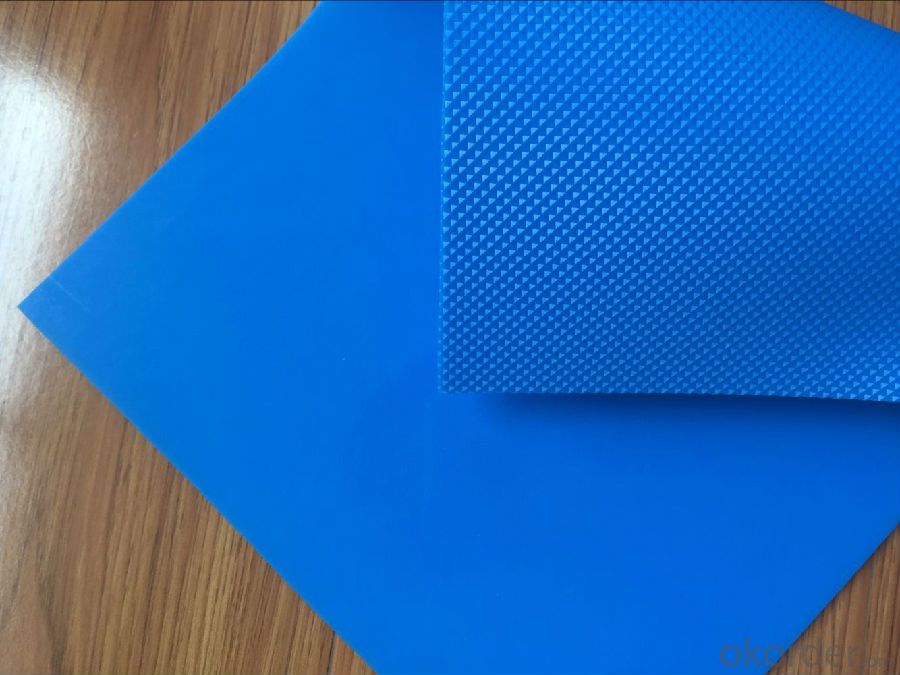

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.PVC Conveyor Belt Specifications:

PVC Conveyor Belt Applications

PVC Conveyor belt has a wide range of products which can be applied in different industries, such as: tobacco, food, logistics, post, airport machinery, phamaceuticals, chemistry, electronics, printing, cable pulling, steel wrapping and sports entertainment.

Photos

- Q:Do olive nets affect the quality of the harvested olives?

- Yes, olive nets can affect the quality of the harvested olives. These nets are used to catch the olives as they fall from the trees during harvesting. However, if the nets are not properly placed or if the olives are left on the ground for too long, it can lead to increased moisture and humidity levels, which can negatively impact the quality of the olives. Additionally, if the olives are not promptly removed from the nets, they can become damaged or spoiled due to prolonged exposure to sunlight or adverse weather conditions. Therefore, it is crucial to ensure proper handling and timely collection of olives from the nets to maintain their quality.

- Q:Plastic shoes taste great, is it harmful?

- But if the smell of plastic shoes is too strong and smells long, there will be smoke and dizziness, which is likely to contain substances harmful to human body.

- Q:How do olive nets affect the overall appearance of the olive fruit?

- Olive nets can greatly impact the overall appearance of the olive fruit. By covering the trees and preventing the olives from falling to the ground, the nets ensure that the fruit remains clean and free from blemishes caused by contact with the soil. Additionally, the nets protect the olives from bird and insect damage, preserving their shape and color. As a result, the olives harvested from trees protected by nets tend to have a more uniform and aesthetically appealing appearance.

- Q:Can olive nets be used for olive trees in regions with limited sunlight?

- It is not recommended to use olive nets for olive trees in regions with limited sunlight. Olive trees require a minimum of 6 hours of direct sunlight daily to thrive and produce a good harvest. Using olive nets in shaded areas may further restrict sunlight and hinder the tree's growth and fruit production.

- Q:Can an olive net be used in both traditional and modern olive farming?

- Yes, an olive net can be used in both traditional and modern olive farming. Olive nets are versatile and effective tools for harvesting olives, regardless of the farming method employed. They can be used in traditional farming practices where olives are hand-picked or in modern farming techniques such as mechanical harvesting. The netting helps to collect the falling olives, preventing them from getting damaged or lost, making it a valuable resource for olive farmers in different farming systems.

- Q:What materials are olive nets made from?

- Olive nets are typically made from durable and lightweight materials such as polyethylene or polypropylene.

- Q:Can olive nets be used for olive trees in regions with frequent storms?

- Yes, olive nets can be used for olive trees in regions with frequent storms. Olive nets are designed to protect the trees and their fruits from damage caused by wind, hail, or heavy rainfall. These nets can act as a barrier, preventing branches from breaking and reducing the chances of fruit loss. However, it is important to ensure that the nets are securely fastened and properly installed to withstand strong winds and storms.

- Q:How do you install an olive net?

- To install an olive net, start by measuring the area where you want to place the net. Next, attach sturdy support poles or anchor points around the perimeter of the area. Then, spread the netting over the support structure, making sure it is taut and covers the desired area. Finally, secure the netting in place by tying it to the support poles or using clips or ropes.

- Q:How effective are olive nets in catching falling olives?

- Olive nets are highly effective in catching falling olives. These nets are specifically designed to be placed under olive trees to prevent the olives from hitting the ground and getting damaged. The nets are made of durable materials that can withstand the weight of the olives and ensure they are collected intact. Additionally, olive nets help in reducing wastage and improving the overall yield during the harvesting process.

- Q:Has the plastic bottle been poisoned for a long time?

- If it is only empty bottle, no hot water and drinking water is used again and again, it is not poisonous. Do you have any poison in the plastic bottle? Just look at the numbers under the bottle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1.8mm Double Sided Polyester PVC Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords