Galvanized Sheet Metal 4X8

Galvanized Sheet Metal 4X8 Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Galvanized Steel Scrap Price Fiber Sheet Price In India Galvanized Steel Prices Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Geomembrane Roll Sheet Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet Price Mdf Price Per Sheet 4Mm Mdf Sheet 1220X2440Mm Price Grp Sheet Price Aluminum Sheet Stock Sizes Cost Of 4X8 Sheet Of Plywood Cost Of Drywall Per Sheet Buy Sheet PlasticGalvanized Sheet Metal 4X8 Supplier & Manufacturer from China

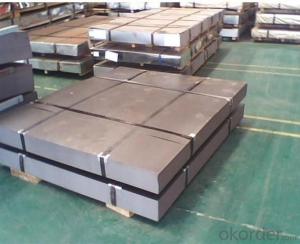

Okorder.com is a professional Galvanized Sheet Metal 4X8 supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Galvanized Sheet Metal 4X8 firm in China.Hot Products

FAQ

- The impact resistance of steel sheets is generally high due to the material's toughness and ability to absorb and distribute energy upon impact.

- There are several sheet metal piercing techniques used for steel sheets, including drilling, punching, and laser cutting. Drilling involves using a drill bit to create holes in the sheet metal. Punching uses a punch and die set to force a hole through the material. Laser cutting employs a high-powered laser beam to melt or vaporize the metal, creating precise and clean cuts. These techniques offer different advantages depending on the specific requirements of the project.

- What are the driving methods for steel sheet piles?

- Common vibration hammer, manipulator and static pressFor more information, look at my company's website in my profile

- Yes, steel sheets can be used for storage racks or shelves as they provide durability, strength, and stability required for supporting heavy loads.

- Indeed, adhesive is capable of easily joining steel sheets. The method of adhesive bonding is widely employed in connecting steel sheets due to its numerous benefits. Adhesives create a robust and long-lasting bond between the sheets, resulting in a seamless connection. Furthermore, they distribute stress evenly across the joint, thereby reducing the likelihood of failure. Moreover, adhesive bonding does not necessitate heat or specialized equipment, making it a cost-effective and efficient solution. However, it is crucial to carefully choose the appropriate adhesive for the specific type of steel, and proper surface preparation is essential to ensure optimal adhesion. All in all, when executed correctly, adhesive bonding effectively joins steel sheets together.

- What are hot and cold plates?

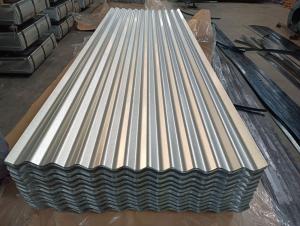

- Cold rolled coil is made of hot rolled coil as raw material and rolled under the recrystallization temperature at room temperature, including plate and coil. Many steel mills in China, such as Baosteel, WISCO, Anshan Iron and steel company, can be produced. Among them, the delivery is called steel plate, also known as "box plate" or "flat"; the length is very long, the volume of delivery, known as "steel band", also known as "coil.".

- Indeed, HVAC applications can utilize steel sheets. In the realm of HVAC ductwork construction, steel sheets are frequently employed owing to their robustness, longevity, and fire-resistant qualities. These sheets can be effortlessly molded into diverse configurations and dimensions, tailored to the precise needs of HVAC systems. Moreover, steel sheets exhibit resistance against corrosion, a pivotal attribute in HVAC applications where moisture and condensation may manifest. All in all, steel sheets are a fitting material option for HVAC applications, given their mechanical characteristics and capacity to endure the demands of heating, ventilation, and air conditioning systems.