Ceiling Light Cover Plate

Ceiling Light Cover Plate Related Searches

Best Inverter For Solar System Led Light For Chandelier Decorative Ceiling Plate For Light Fixture Inverter For 5kw Solar System Parts For Light Fixtures Transformer For Light Fixture Decorative Lights For Ceiling Lights For Kitchen Ceiling Ceiling Brackets For Lights Hanging Ceiling Chairs For BedroomsHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Aluminum Bar Stock For SaleCeiling Light Cover Plate Supplier & Manufacturer from China

Okorder.com is a professional Ceiling Light Cover Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Ceiling Light Cover Plate firm in China.Hot Products

FAQ

- Light steel keel CB38 * 12 What does it mean?

- Refers to the main keel with 3.8cm × 1.2cm, which is often said 38 main keel. There are 38 holes in the wall

- Construction Process of Light Steel Longguard Paving

- Construction points (1) according to the design of the ceiling height on the wall line, the level of tolerance ± 5 mm. (2) boom installation 1) choice of boom. Generally speaking, light steel keel ceiling selection of the boom can be based on the standard map, light steel ceiling selection diameter 6, medium, heavy selection of diameter 8. If the design has special requirements, the load is large, you need to be determined by structural design and verification. 2) According to the design or standard map to determine the hanging point spacing. Generally not on the ceiling between the 1200 ~ 1500 mm, the ceiling distance of 900 ~ 1200 mm. 3) fixed ceiling. For the cast-in-place concrete roof can be embedded in the construction of embedded boom or embedded iron, so that the boom and iron welding. In the old building or concrete orifice can be used under the nail gun hanging point iron (small angle iron) fixed, need to add a gasket. The nail must be secure (if the nail is perforated, the boom can be used to fix the boom). Or the expansion bolt under the lifting point. 4) When the boom is installed, the upper end should be welded with the embedded piece, the lower end should be set with thread, with a good nut, the end of the thread exposed to not less than 3MM.

- I'm wanting to paint 1 Corinthians 13 on our bedroom ceiling in some sort of spiral design. I just want it to be pretty and look professional. I'm weary about doing the spiral design thought because I just don't know how I would get it just right... but I can't think of any other design that would look right.. I think it would look funny just written straight across on the ceiling. Anyone have any ideas or tips on doing this?

- I agree that it might be nice as a border or on the wall. If you really want a spiral on the ceiling you ought to do it first on a big piece of tracing paper and then transfer it onto the ceiling. (It would be really hard to work free hand on the ceiling and have it look nice) There are various ways to transfer using the paper like tracing over the back of the letters with a special soft pencil then putting the paper in place and re tracing over the front of the letters. It will leave a faint line for you to paint over later.

- Both sides are empty light steel keel partition in the middle to conceal the socket, switch box, how to be fixed

- Install the switch and socket where the hidden wooden keel or woodworking slats to facilitate the self-tapping nail fixed bottom box.

- Light steel keel wall hidden acceptance of what is the hidden content? (Not a ceiling)

- 1. The variety, specification, performance and moisture content of the keel, fittings, wall panels, filling materials and caulking materials used in the skeleton walls shall meet the design requirements. There are sound insulation, heat insulation, fire retardant, moisture and other special requirements of the project, the material should have the appropriate performance level of the test report. 2 skeleton wall works Border keel must be firmly connected with the base structure, and should be flat, vertical, position is correct. 3 skeleton in the keel spacing and structure of the connection method should meet the design requirements, the skeleton of the equipment pipeline installation, doors and windows openings and other parts to strengthen the keel should be installed firmly, the correct position, fill the material should be set to meet the design requirements. 4 wood keel and wood wall panel fire and corrosion treatment must meet the design requirements. 5 skeleton wall wall panels should be installed firmly, no delamination, warping, cracks and defects. 6 seam joints used in the joints of the wall method should meet the design requirements. 7 skeleton wall surface should be smooth, consistent color, clean, no cracks, seams should be uniform, straight. 8 skeleton on the wall of the holes, grooves, boxes should be the right position, sets of anastomosis, neat edges. 9 skeleton wall filled with the material should be dry, fill should be dense, uniform, no fall.

- Acceptance specification and standard of light steel keel in decoration engineering

- Light steel keel opening edge to ensure that neat, mouth care should not leak, to ensure tightness. There are many kinds of test methods, such as hand pull, observation, size and so on. As for the surface of the cover panel should be flat, the same color, very clean, from the arch is very accurate, no hammer, pitting and so on. Light steel keel panel joints should be located on the keel, to maintain uniform, the pressure is very straight, and no warping, seams tight, did not disclose. If the ceiling has a molding requirements, modeling size and location should be accurate, beautiful and smooth curve.

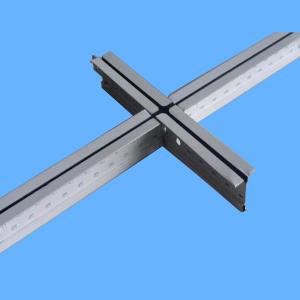

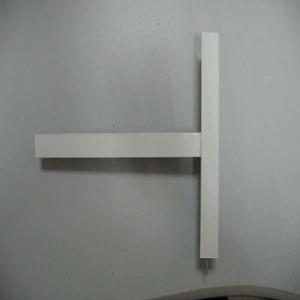

- How do I install dropped ceiling in basement?

- Get your layout, mains will run every 4 feet perpendicular to your beams. You need a wire every 4 foot down each line a main will run. You can attach the the wires that hold up your mains to your joist by looping them over a beam or you can get screw eyes and screw them into your beam and run your wire through the eye of the screw. Ties these wires and leave them hanging down about 8 below your desired ceiling height. Get a level mark 1 above the height you want your ceiling in 2 corners, pop a chalk line and screw your wall molding with the top touching the chalk line you popped. If you are new at this the easiest way to start your layout is to cut the tab off 1 end of the mains, put the cut end on your wall molding attach a hanger wire to hold the main in place. Do the same with another main and hang. Measure 4 foot from the wall mold and snap in a 4' tee to connect the 2 mains together. Tees will go every 4 foot connecting the mains to each other. Then snap in a 4' tee between the 4'ts in the same direction of the mains. This creates a 2x4 grid pattern. If you want 2x2 grid you will insert 2' tees in between the 4' tees. You will need to tie the hanger wires into the mains and remember to keep them level. (run a string from side to side to keep level if you don't have access to a laser). Also remember to check your grid to make sure you are keeping it squared, measure a 2x4 rectangle from corner to corner diagonally to make sure each measurement is the same. (dropping in a tile from time to time will help you keep square as you go. main.main.main.main.main.main t .............t..............t.............. e.(4' tee)..e.(4'tee)...e.(4'tee)...e.(4'tee) e ............e.............e............e... main.main.main.main.main.main