Aerate Garden Soil

Aerate Garden Soil Related Searches

Galvanized Steel Garden Bed Steel Outdoor Bench Alside Pvc Aluminum Trim Coil Aluminum Pipe Stock light bond plus aluminum China Rattan Furniture Hunter Green Aluminum Trim Coil Aluminum Angle Iron Aluminum Vinyl Siding Trim Coil 24 X 50 Aluminum Trim CoilHot Searches

Stainless Steel Supply Near Me Steel Girder Cost Stainless Steel Tubing Near Me Stainless Steel Welder Near Me Stainless Steel Shop Near Me Stainless Steel Welders Near Me Stainless Steel Near Me Lasani Wood Sheet Price Garden Slabs Sale Garden Bench Sale Garden Supply Company Catalog Local Garden Supply Stores Buy Wood Screws Heated Wood Floors Cost Wood Trim Suppliers Used Hotel Patio Furniture For Sale Cost Of Awnings For Decks Japanese Garden Statues For Sale Garden Decorations For Sale Garden Awnings For SaleAerate Garden Soil Supplier & Manufacturer from China

Okorder.com is a professional Aerate Garden Soil supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aerate Garden Soil firm in China.Hot Products

FAQ

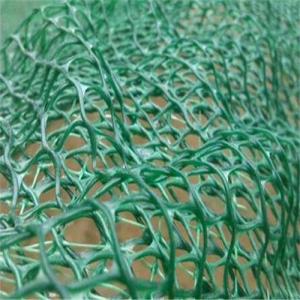

- There are several types of geosynthetic reinforcements that can be used for bridge decks, including geotextiles, geogrids, and geocomposites. Geotextiles are permeable fabrics that can be used to separate different layers of soil, provide filtration, and prevent soil erosion. Geogrids are typically made of high-strength polymers and are used to reinforce soil or aggregate layers, improving their load-bearing capacity. Geocomposites combine the properties of geotextiles and geogrids, providing both separation and reinforcement functions. These geosynthetic reinforcements are commonly used in bridge deck construction to enhance stability, improve durability, and reduce maintenance requirements.

- Earthwork products, such as soil, gravel, and rocks, play a crucial role in determining the overall structural stability of a project. These materials are used as foundations, backfills, and retaining structures, providing support and stability to the structures built on top of them. The quality, properties, and compaction of earthwork products directly influence the load-bearing capacity, settlement, and resistance to external forces of a project. Proper selection and compaction of these materials are essential to ensure the long-term stability and safety of the project.

- Geosynthetic liners prevent seepage in wastewater treatment plants by acting as a barrier between the wastewater and the surrounding environment. These liners, made of materials like geomembranes and geotextiles, are impermeable or have low permeability, effectively preventing the escape of contaminants into the soil or groundwater. Additionally, they provide stability to the structure, reducing the risk of leaks and maintaining the overall integrity of the wastewater treatment plant.

- The lifespan of geosynthetics in earthwork applications varies depending on the type of material, the specific application, and the environmental conditions. However, when used and installed correctly, geosynthetics can have a lifespan ranging from 20 to 100 years.

- Using geocells for load support in railways offers several benefits. Firstly, geocells are lightweight and easy to install, making them a cost-effective solution for improving the load-bearing capacity of railway tracks. Secondly, geocells provide excellent soil confinement, preventing lateral movement and enhancing stability, which is crucial for maintaining track alignment and reducing settlement. Additionally, geocells distribute the load evenly, reducing stress on the underlying soil and preventing track deformation. This leads to improved track performance, reduced maintenance requirements, and extended service life of the railway infrastructure. Finally, geocells are environmentally friendly as they can be made from recycled materials, contributing to sustainability efforts in railway construction.

- Geosynthetic liners act as a barrier between contaminants and the surrounding environment, preventing leakage by providing a strong and impermeable layer. They are designed to resist chemical degradation, punctures, and tears, ensuring that hazardous substances, such as pollutants and waste materials, are effectively contained and do not seep into soil or water sources. Additionally, these liners can be engineered to enhance their performance by incorporating geotextiles and geomembranes, further minimizing the risk of contaminant leakage.

- I am now reading materials science and engineering, when the entrance examination, then you can report civil engineering professional?

- It can be. But it is best to choose the relevant direction of civil engineering materials.