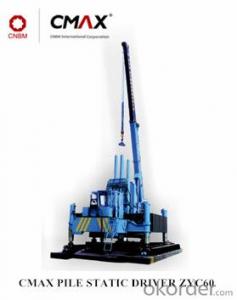

ZYC60 Used Pile Driver Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZYC60 Used Pile Driver Hydraulic Static Pile Driver for Sale

| Lower Energy Consumption: |

>>We use variable hydraulic systems with low loss and constant power in this series of products, so that energy consumption decreases by 30% and working efficiency increase by 60%. |

| High Efficiency: |

>>To ensure the high working efficiency of the whole machine, we use hydraulic systems with big power and great flow, the pile driving mechanism with multi-speed control and being quick in getting ready for operation. |

High Reliability: |

>>To ensure the high reliability of our products which engineering machines should possess, we improve the design and use very reliable materials or components which we select carefully in the process of purchasing. |

|

Convenience in dismantling, transportation and maintenance: |

>>Since we have constantly improved our design of pile drivers for more than 10 years, every part of the machine is easy to be taken apart, which provides convenience in transportation and maintenance. |

|

Multi-function: |

>>Our products are multi-function static hydraulic pile drivers with embracing pile driving, top-pressing pile driving or both at the same time because they are well combined with each other. |

|

Systemization and Maximization: |

>>Our company has developed 14 models of pile drivers with the capacity of 60 tons to 1200 tons and each model is classified into 4 kinds according to its function with the maximum tonnage of 1200. |

|

Flexibility in Designing: |

>>To keep up with the development in the engineering machinery of the world, we will integrate all useful high technologies from machine-building, electricity, hydromechanics and electronics into our products and meet different individual needs of our customers. |

|

| Two Patents: |

>>The design of inverted cylinder as a supporting leg which avoids the radial force on the piston extends the life-time Of the cylinder. |

| Parameter/Model | ZYC60 | |

|---|---|---|

| Rate piling pressure(KN) | 600 | |

| Piling speed(m/min) | Fast | 4.0 |

| Low | 1.1 | |

| Piling stroke(m) | 1.4 | |

| Pace(m) | Longitudinal | 1.4 |

| Horizontal | 0.4 | |

| Angle range(°) | 15 | |

| Rise stroke(m) | 0.6 | |

| Square pile(mm) | Max | 300 |

| Circle pile(mm) | Max | ... |

| Side piling(mm) | 400 | |

| Corner piling space(mm) | 800 | |

| Lifting weight(t) | 5.0 | |

| Pile hanging length(m) | 7 | |

| Power(KW) | Piling | 15 |

| Lifting | 7.5 | |

| Main dimension(m) | Work length | 5.44 |

| Work width | 3.8 | |

| Transpot height | 2.6 | |

| Total weight(t) | 60 | |

Advantages

1 sincere

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the outdoor heaters produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to answer your questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s outdoor heater have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

Others

1.Reply your inquiry in 24 working hours.

2.Experienced staffs answer all your questions in professional and fluent English.

3.Customized design is available. OEM is welcome.

4.Exclusive and unique solution can be provided to our customer by well-trained and professional engineers and staffs.

5.Special discount and protection of sales area provided to your distributor.

6.Do the best reliable heavy-duty single drum vibratory road roller in China.

7.Warranty period is 1-year or 1500 working hours against Bill of Lading.

Company Information

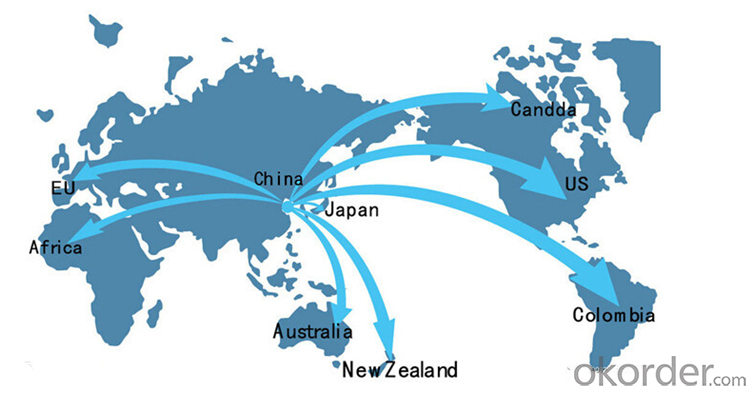

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

e. To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

f. On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

g. Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q:Code for installation and operation of pile drivers

- First, piling machine operators must be familiar with the structure of the machine, performance, operation essentials and safety precautions, after passing the test and obtain a certificate, you can operate alone.Two, operators must concentrate on the operation. Do not talk, laugh, play or make trouble with unrelated persons. No smoking or food is allowed during the operation.Three, strictly abide by the relevant provisions of the maintenance of pile drivers, conscientiously do all levels of maintenance, to ensure that pile drivers are often in good condition. And pay attention to the rational use, correct operation.Four, the pile driver in the work should be prepared for the following:1, to the construction staff understand the construction conditions and tasks, and construction problems found in this class should pay attention to matters.2. Adjust the position of the speed change gear of the pile driver according to the vibration force required by the construction personnel.3. Check whether the insulation of cables and wires is good. Check that the controller's contacts are good and that the bounds are correct.

- Q:What is the difference between piling and piling?

- the center of the city, hammer smoke and noise nuisance, environmental protection is generally not let the surrounding residents also opposed. From the environmental point of view, low environmental impact pile, and the impact on the surrounding pile is much smaller than the pile.

- Q:Do you make money on building pile drivers? How long will it take to recover the cost?

- To be honest, no money, no problem, it's hard to have a client.My father worked as an electrician at the construction site for three years. I just asked him.Of course, you have connections, and you won't do it.The most crucial thing is the network, there is a market, that thing good, tens of millions, smashing hands, crying dead.Sure, you have connections, when I don't say..

- Q:Such as the title... Phenomenon: quiet with a sound to length, rises again, continuous... Better knowledge about this point for more,...

- Hammer sinking pipe pile driver is a kind of large-scale machinery used in the construction of cast-in-place pile foundation. The general is a hammer a hammer down to the design depth, pipe are arranged at the front end of the pile head, to prevent dirt from entering the immersed tube. Then, the concrete is poured into the immersed pipe sleeve, and the concrete side lifting pipe is poured in the side, and the vibration is generated in the process of lifting the pipe, so as to achieve the compactness of the concrete.

- Q:Types of pile drivers

- Spiral pile driver (Spiral hammers) is a power driven drill head drill bit into the underground drilling machine drilling equipment. The spiral pile driver can be divided into two parts: the pile foundation and the drilling part.

- Q:What is a loading type road pile driver?

- The emergence of the loader pile driver is a breakthrough in the piling machine industry. It not only improves the efficiency of drilling, but also has the ability to work at night as well as the ability to prevent rain and water. It has longer life, better quality and, of course, more expensive prices. But in general, it's good value for money.Traditional road pile driverThe traditional highway pile driver doesn't have the working conditions at night and rainy day, but the punching efficiency is high, but it is not as good as that of the loading type road pile driver. It looks shabby.?Turn left and turn right |Loading type road pile driverThe utility model relates to a loading type road pile driver, which has the advantages of high efficiency and punching efficiency, is 1.5 times as much as that of a traditional pile driver, and has a special driving room. Ability to work at night and on rainy days. The power consumption is the same as that of a general pile driver. He looks very handsome, too.Turn left and turn right |From the picture we can see briefly that the loading type road pile driver is much better than the general road piling machine and looks better. The operating room is not as simple as this.

- Q:Which brand is better for a small pile driver?

- the configuration of the machine and customer service service, selective highest bid is the best policy, piling machine personal feeling of Shandong Lida Company can, the landlord statements of a school for reference!!

- Q:Is the architecture of the pile driver strong in single core performance or multi - core capability? Or?

- Compared to the K10.5, the performance of bulldozers and pile drivers did not rise or even decline.Multicore is stronger because it's simple - more nuclear......

- Q:What is the noise level of site construction (piling)?

- The construction is divided into several stages, and the noise limits are as follows:Earth stage, daytime noise limit is 75 dB, the night noise limit is 55 dBPiling stage, daytime noise limit is 85 dB, prohibit the construction of the night

- Q:Multilayer, six layers! Real Estate Company real estate. I would like to ask you to build the foundation is a good pile or independent column good? May I have some questions from insiders?! Thank you

- Depends on geological reports, can not pile, it is best to save a lot of money Oh!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ZYC60 Used Pile Driver Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords