ZrO2 14.5% AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ZrO2 14.5% AR glass fiber roving

AR glassfiber spray roving is used for spary up or mechanical continuous formed GRC, such as formwork roof board, decoration panel, garden feature. It has widely used in tunnel, mine shaft, protect slop, spray-up roving for reinforcement surface and tip of wall.

Specification of 14.5% Zro2 AR Glassfiber roving:

1.ZrO2 14.5% & 16.5%

2.2400Tex

3.Filament dia 15um

4.Moisture Content 0.09%

5.Breaking Strength 0.28N/tex

Technical Data of 14.5% Zro2 AR Glassfiber roving:

ZrO2 Content | % | JC935-2004 | 14.5±0.8 | 14.8 |

TiO2&ZrO2 Content | % | ≥19.2 | 19.3 | |

Filament dia | um | GB/T7690.5-2001 | 15±2 | 15 |

Strand tex | tex | GB/T7690.1-2001 | 2400±240 | 2460 |

Breaking Strength | N/tex | GB/T7690.3-2001 | ≥0.25 | 0.28 |

Moisture Content | % | GB/T9914.1-2001 | ≤0.2 | 0.09 |

Combustible Content | % | GB/T9914.2-2001 | 0.8-2.0 | 1.35 |

Stiffness | mm | GB/T7690.4-2001 | ≥120 | 150 |

Specific gravity | g/m3 | / | / | 2.7 |

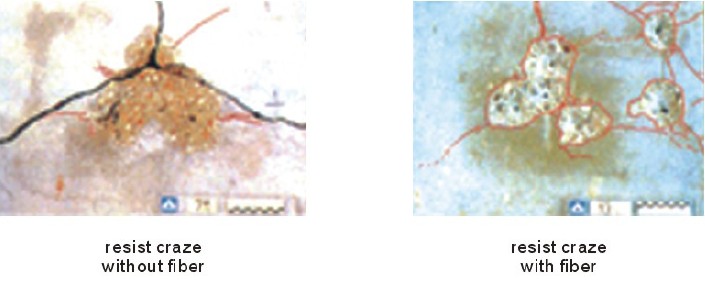

Crack Test on 14.5% Zro2 AR Glassfiber roving:

Pallet Packing of 14.5% Zro2 AR Glassfiber roving:

1. Each pallet has 3 or 4 levels ,16rolls /level. 860-1150kg/pallet.

2. 20pallets/1x20”GP 17-20MT/1x20’GP

- Q:Can anyone lead me in the direction, or link the article, to prove that cement in a fine powder either in the air or by itself can be/is flammable and/or explosive.... The reason I ask this is because there is a project that requires touch cutting a silo and there is a fine cement powder layer on the silo and its surroundings, and I advised it to be cleaned before cutting, but the weld/cut team seems to think that it is safe for the fact that it is just cement... are they right or will it explode.... the silo is also filled with 15 tons of fine cement powder... where the slag will fall...

- Cement powder is not flammable or explosive. If it were, there would be a hazardous material symbol on the silo. There are other reasons to clean up the dust, such as the fact that breathing the dust may be hazardous and that it may be required by law. If they cut into the silo, then slag may contaminate the cement. Your best bet is to do a search on Material Safety Data Sheet Cement.

- Q:I am buying a home and would like to 'dress up' the back patio area, but don't want to spend a fortune on tile for outdoors...was thinking about staining the front porch and back patio...but I don't know what this would entail...any help? THANKS!

- My bedroom floor is stained concrete. We ripped up the carpet in there, the living room and the front office/living area when we moved into our house. I also stained the back patio to look like terra cotta tiles. I loved my bedroom floor so much that even though we eventually put flooring down in the rest of the house I refuse to even consider it. The color I got at home depot is a sheer golden sun, we used an all purpose sprayer (the 2 gallon kind for bug spray) and then just layered it over the floor. Make sure the floor is clean or you will have a nightmare with dust or dirt residue. Then after you spray it, seal it with a clear cement sealer. You can do patterns, or a solid color, or make it look like stone. I have some very small rugs right by the bed on either side for warmth, but the staining effect looks great!

- Q:where do you buy dental cement?

- the dentist told me that they use super glue. i tried it on a cracked tooth cuz i couldnt get in till the next week and it held. not only did it hold but it held so good the dentist had trouble getting it off. She said its not toxic unless swallowed. We use a formof it for cuts in the hospital. there are videos on line on how to do it right. it works. the stuff in the store doesnt work very well.

- Q:What would happen if someone where you flush cement mix down the toilet and should I do it.

- I agree with both of the top 2 contributors. Depending on how much you flushed down will decide whether you do damage or not. A couple of tea spoons unlikely to do harm a shovel full keep flushing for a long time

- Q:I am in UZbekistan. We need to buy G class cement but we dont have such a brand name locally. So I would like to know what are the parameters of G class cement as we might have such a cement produced locally but it might have dofferent classification name.

- I did a little looking around on the net. It seems that Class G cement is an oil field cement and is referenced to a American Petroleum Institute (API) classification. I didn't have time to reseach it further, but you may find something at their website

- Q:In a CSI episode, a guy filled his letter box with cement because his letter box was getting destroyed every night. He had 4 destroyed, had enough and decided to fill the next one with cement. What happened was two guys drove past with a bat, the guy swung to hit the letter box but because it went wrong they crashed and died. The owner buried the letter box, replaced it but of course the CSI team figured it out...and he was arrested. What was the crime he committed? I mean, he had to pay for the replacements so why is he being punished for trying to protect his property? He didn't mean the boys any harm, he was just trying to save his letterbox...

- Cement Mailbox

- Q:I live in a bright purple cement rendered home and want to paint it dark grey, but am unsure what paint to use or if I have to do any preparation to it before painting itPlease helpBrands available in Australia will helpThanks

- First, try using a power washer in the 2000 PSI range to take off the old paint. If it comes off (or most of it, anyway), let the cement dry for a couple days and then use a concrete primer before applying a color coat specifically made for concrete. The primer is especially acidic, so it really soaks into the cement (and it doesn't go very far, because so much soaks into the concrete). The concrete color coat is then designed to hold onto the primer and provide a solid moisture barrier. If the old color won't come off, don't worry. Just clean it up as best you can before applying the primer and paint. And, use top name brand paints (like Dunn-Edwards or Sherman Williams). The more expensive products will cover better and may actually be cheaper in the long run (less coats and time to paint).

- Q:Thinking about playing a trick on my kids with little footprints on the cement porch. Would food coloring wash out, or should I use something else?

- You would likely have to use something that is water soluble because cement is porous and will absorb liquids on its surface. If it were me, I wouldn't use food coloring, I'd use water color paint. You could probably find it at a hobby store. If the cement area where you are planning this caper is exposed to the weather, the footprints should disappear after a short time. If they need to disappear more quickly, some diluted bleach would speed the process along. You can also speed the process of making the tracks by making a stamp from a potato. Just carve enough away from the potato to leave a mound that sticks out/up in the shape you want the tracks. You can then just dip the potato into whatever colored mixture you decide on, and quickly stamp your tracks on the cement. That would be quicker than drawing the tracks if you're planning on quite a few tracks. Good luck with the prank!

- Q:and it was lumpy can i still use it or will the lumps interfer with the leveling process, ( and how liquidy should i make it) i experimented with a little amount and it just didn't look right so i threw it out.. it's the firt time i'm using a self leveling product

- You want to mix the stuff so that it is like pancake batter. No lumps. The lumps are clumps of still dry concrete. Self leveling works like water.-which is level- So your surface that you want to have level needs a fence all around the perimeter say 3/8 x 2 wideplywood strips in a continuous border......then in the lower centre area (in many cases, the floors of houses, the heating wires get laid - - and then the leveling cement is poured onto the floor(it is runny like batter) and covers the wires and is stopped at the level of just under 3/8. Then it is left alone for a day or three. Then floor tile are dry laid ontop of the level floor....then glued down.

- Q:color- white cement

- From the interwebz. You can buy ANYTHING from the internet! :)

1. Manufacturer Overview |

|

|---|---|

| Location | Shanxi, China |

| Year Established | 1982 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port, China |

| Export Percentage | 41-50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese; |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

ZrO2 14.5% AR Glass Fiber Roving

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Kgs m.t.

- Supply Capability:

- 100000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords