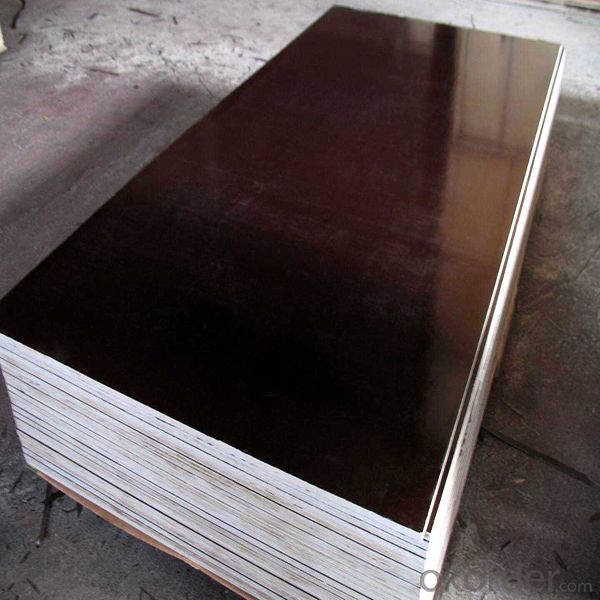

ZNSJ brown film faced plywood malaysia plywood

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 1220*2440*12

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

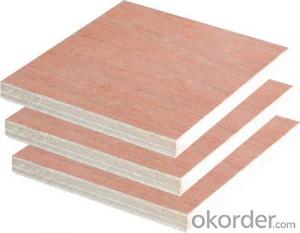

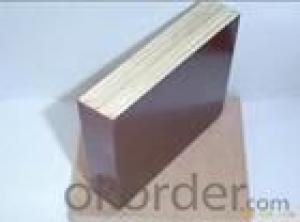

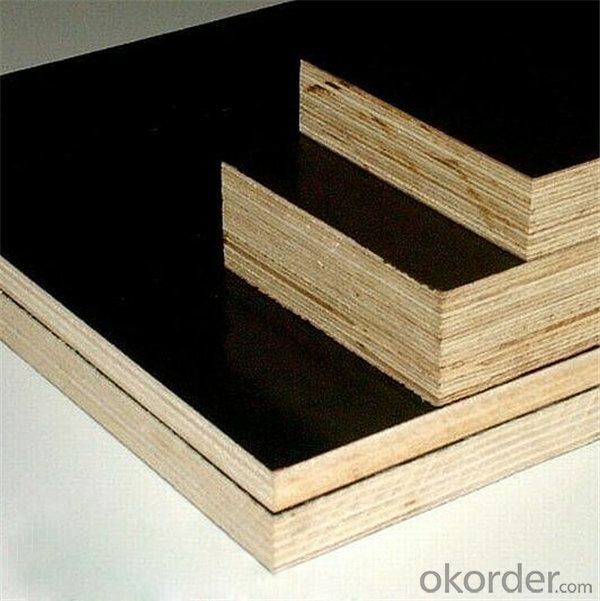

ZNSJ brown film faced plywood malaysia plywood

Dimensions of ZNSJ brown film faced plywood malaysia plywood: 1220*2240*(10-20mm),915*1830*(10-20mm)

Product Features of ZNSJ brown film faced plywood malaysia plywood :

1,Adopting the high quality poplar ,whole core and first grade,no holes in the middle of plywood after sawing, which can gurantee the toughness of the template;

2,Using the melamine glue from core to face, high glue concentration, which can gurantee glue adhesiveness ;

3,Adhering them manufacturing principles that each core board is with layer by layer gluing and with high pressure.Layer by layer gluing can fullly bond that impove 10-15% bonding strength. The hot pressure is 120% higher than the theoretical one ,avoiding to reduce pressure to keep the thicknes. The turnover of finished film faced plywood( Concrete formwork panel ZNSJ high quality plywood ) can be up to 10-15time, which ensure product be more durable;

4, two times sanding (secondary molding) before film facing ensure the smoothness of the template without burrs and groove marks.

Product Application of ZNSJ brown film faced plywood malaysia plywood: High- rise construction,building construction, forming concrete,can be widely use for building concrete .

Items | Parameters | |||||

Plywood size: | 1220*2440mm , 1830*915mm,4*8 ft,3*6ft | |||||

Plywood name | Film faced plywood, wooden formwork, wood formwork, Marine Plywood,Construction Plywood,wooden construction formwork,Concrete formwork panel,shuttering plywood, shuttering formwork,ZNSJ brown film faced plywood malaysia plywood | |||||

Glue | Melamine glue/MR WBP | |||||

Core | pine,hardwood,eucalyptus,combi etc | |||||

F/B | Black film, brown film, anti-slip film | |||||

Thickness tolerance: | +/-0.5mm | |||||

Standard quality | natural wood face, one time hot pressing | |||||

High quality | double side film faced,twice hot pressing and sanding | |||||

thickness: | gross weight ( kg/pcs) | 20ft container (pcs) | 40ft container (pcs) | Using times | ||

13mm | 25.16 | 690 | 870 | 6~15times | ||

14mm | 27.12 | 640 | 810 | 6~15times | ||

15mm | 29.05 | 600 | 750 | 6~15times | ||

Item | Unit | Standard value | Test result | |||

Moisture | % | 6 ~14 | 9 | |||

Adhesive Force | Mpa | ≥0.7 | 0.76 | |||

Bending strength | Longitudinal | Mpa | ≥24 | 36 | ||

Cross | ≥20 | 22 | ||||

Elastic Modulus | Longitudinal | Mpa | ≥5000 | 5980 | ||

Cross | ≥4000 | 4850 | ||||

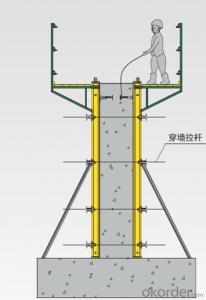

- Q:Technical specification for construction formwork safety JGJ162-2008 who has made me please

- Template design and construction, from the actual situation of engineering, reasonable selection of materials, scheme and construction measures; should satisfy the template in the transport, installation and use of the strength, stability and stiffness requirements, and should give priority to the finalization, standardization and template template support components, reduce production and installation workload. To improve the reuse rate.The design, manufacture, installation and removal of the 1.0.4 construction formwork shall be in conformity with the requirements of this code, and shall comply with the relevant provisions of the state.

- Q:What is the use of building wall formwork support? Thank you

- In the construction for concrete cast-in-place construction formwork supporting structure, widely used in steel or timber beams assembled into the template bracket

- Q:1, JGJ162-2008 construction formwork safety technical specification;2, JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications; the friend has. Send me thanks

- 3 2.1.12 flying die flying shuttering mainly by the platform board, support system (including beam, support, support, legs, etc.) and other accessories (such as lifting and walking mechanism, etc.). The utility model is a large tool type template, which is called a table mould or a table model because of the appearance of the utility model. Because it can take advantage of lifting machinery, pouring from the well under the floor of the lift out of the transfer to the upper layer of repeated use, so called flying mode. 2.1.13 tunnel mode tunnel shuttering a combination of stereotypes template, while pouring concrete wall and floor of the template, because the shape of the template like a tunnel, it is known as the tunnel model.

- Q:Since the building, and I would like to ask some of the basic knowledge to the construction of a unified drawing, plus or minus 0 and the height of the drawings, the roof slope requirements. Now the blue steel reinforced concrete inclined roof beams or do. Here we use multiple beams, and the waterproof, thermal insulation, in tile. Anyway, many shortcomings is wood, attic space basically scrapped, there is a fire started...I would also like to use concrete flat top, that is, do not let, more depressed.If I can use wooden beams, waterproof SBS, hanging plastic extruded board?The construction of plastic extruded board in inclined roof beams hung strong? Construction is not difficult?As well as the 8X11 meters of the roof, 30 degrees slope, sloping roof concrete cost about? I feel modeling and cloth reinforcement are very troublesome, expensive cost estimation

- You can put the beam properly after the play flowers on top, which is the slope of the wall, so that you can

- Q:What is the building template support

- (1) the material of the template support: high performance cold rolled steel, thickness of 2.5 mm to 2.7 mm, the new material is characterized by: corrosion resistance, elasticity, strong deformation.(2) the specification of new steel building formwork support:

- Q:86335 template support, what is the concept of those advantages

- In the case of the construction industry, after 20 years of this industry, dedicated to technical analysis and improvement. After painstaking research, invited the domestic industry elite Magi to discuss, repeated demonstration, combined with the actual measurement through the practice of technical staff, spend long time hard work. Finally invented this new type of digital steel template support combination structure, so far spent ten years of painstaking research on the huge sums of money technology finally succeeded. To fill the gaps at home and abroad (with our understanding of the current international and domestic architectural template combination structure has not been any new structure), and won the national invention patent.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ZNSJ brown film faced plywood malaysia plywood

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

- Option:

- 1220*2440*12

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords