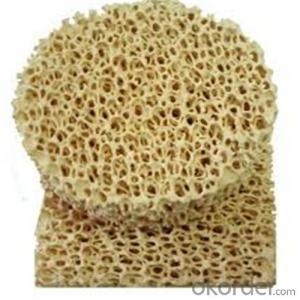

Zirconia/Alumina Ceramic Foam Filter for Iron Foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Alumina Ceramic Foam Filter for Iron& Steel Foundry

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Material: | PU foam (polyurethane foam) | Size: | Customized | Mesh: | 10 ppi to 60 ppi |

| Property 1: | Mend structure of crystalloid | Property 2: | Reduce foreign matter | Property 3: | Stable chemical property |

| Property 4: | Stable purifying efficiency | polyurethane foam filter: | polyurethane foam |

Packaging & Delivery

| Packaging Details: | carton and pallet, or as customers' requirement |

| Delivery Detail: | 30 days after receiving the downpayment |

Specifications

Alumina ceramic foam filter

1.even aperture, high porosity, proper sinter

2.high strength of anti-flexing and anti-compression

Alumina ceramic foam filter

The product, adopted good portiforium foam and high purity ceramic , effectively removes non-metal solid mixture from aluminium and aluminium alloy fusant.

Application:

For the filtration of molten steel and alloy,large scale iron casting

Product standard:China national GB/T 25139-2010

Zirconia ceramic foam filters are determined for filtering of steel and steel alloys up to the temperature of 1700 °C.

Filters are recommended especially for high quality grades of alloys.

-Drop turbulent of molten steel and alloy

-Improve accepted rate of steel casting

-Reduce foreign matter of steel casting

-Drop twice oxide flaw

-Reduce second-face flaw after machine process

Advantages:

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

Ceramic foam filters are different from aperture specifications from 10 to 45ppi, with different sizes and shapes.

Besides the general specification ,we can offer the product according to the customers requirements.

Form A Ceramic foam filter capability

Thickness mm | Aperture PPi | Volume intensity g/cm3 | Tortuous intensity in normal temperature N/cm2

| Pressure resistence intensity in normal temperature N/cm2

| Pressure resistence intensity in high temperature N/cm2

| Refractory temperature

| Air discharging capability cm3/g

| Porosity %

|

15-100 | 10-45 | 0.35-0.45 | ≥38 | ≥80 | ≥45 | ≥1800 | ≤5 | ≥85 |

Form B 25ppi capability of typical pouring of ceramic foam filter

Specification mm | Area M2

| Maximum metal volume of pouring (kg/min) | Optimum volume of pouring (kg/min) | Typical capacity of filtering (T) |

178X178X50 | 0.0213 | 57.00 | 25-45 | 4.2 |

229X229X50 | 0.0387 | 118.00 | 35-102 | 6.9 |

305X305X50 | 0.0745 | 198.00 | 90-165 | 13.8 |

381X381X50 | 0.122 | 325.80 | 130-265 | 23.2 |

432X432X50 | 0.160 | 427.20 | 210-350 | 34.5 |

508X508X50 | 0.227 | 606.60 | 280-465 | 43.7 |

585X585X50 | 0.341 | 772.20 | 370-540 | 57.3 |

Other products:

For Us:

Welcome to visit our factory~

- Q:What is the filtration accuracy of 50nm ceramic membrane?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q:Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q:What are the causes of the powder moisture in the ceramic filter?

- Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q:How much is the accuracy of 50nm ceramic membrane filtration?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q:Why should filter core be used in backwash of ceramic filter?

- Ceramic filter recoil stage is with certain pressure of clean water from the inside out washing ceramic filter plate, the outer aperture ceramic filter plate from inside is gradually reduced, such as flushing water and unclean inside contain impurities that may block ceramic filter board, other structures in the recoil stage of pollution. Such as recoil, water is not clean, you must go through the water filter cartridge to filter again, the choice of filter core, the higher the accuracy of filtration, the more clean water, but the filter is more likely to plug, scrap. Of course, the water is clean and contains little solids. The filter core is not easy to plug and even water filters can be removed.

- Q:Can the ceramic plate filter the hot air?

- The cleaning of the ceramic filter is divided into two parts: reverse flushing (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board. Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure. Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.). Other reasons such as 1,2,3 are normal, but can not be discharged from the spindle speed too fast, even the ceramic filter itself manufacturing defects, the user equipment modification and so on, are likely to lead to abnormal operation of equipment. We specialize in ceramic filter boards for many years and welcome exchanges.

- Q:The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q:What happens when the pressure on the filter plate is uneven during backwashing?

- Ceramic filter is a kind of solid-liquid separation, dehydration drying equipment, such as dehydration pulp, mortar. The backwash of ceramic filter is to flush the filter medium (ceramic filter plate) with clean water with a certain pressure.

- Q:The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q:How should the static and dynamic sealing points of the ceramic filter be leaking?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Zirconia/Alumina Ceramic Foam Filter for Iron Foundry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords