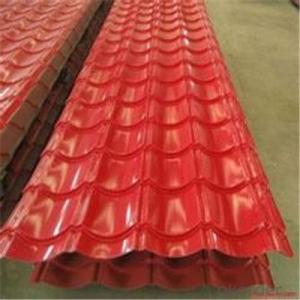

Zinc Coating Galvanized Corrugated Steel Iron Zinc Roof Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of Corrugated Iron Sheet:

1) Capacity: about 15,000 tons per month for sheet product.

2) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer's request

3) Thickness: 0.13mm-0.5mm

4) Width: 400mm-1000mm

5) Length: We can adjust the length according to your request

6) Zinc Coating Weight: 60g/m2-275g/m2

Specifications of Corrugated Iron Sheet:

Standards: GB, JIS3312 and ASTM

Materials: SGCC, Q195-Q235B, SPCC, DC01, DX51D+Z and more

Thicknesses: 0.23-1.0MM

Widths: 600-1200mm

Zinc coating: 80 to 275g/m²

Features of Corrugated Iron Sheet:

Spangle: Regular spangle, minimized spangle and zero spangle

Hardness: Full hard, normal

Color: RAL, or other series

Surface Protection: PE, PVC, PVDF, SMP, HDP, etc.

Min trial order 10 tons each thickness, 1x20' per delivery.

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q:How do steel sheets perform in marine environments?

- Steel sheets are well-suited for marine environments because they possess high strength and corrosion resistance properties. The presence of saltwater and high levels of moisture in these environments can cause significant damage to many materials; however, steel sheets are specifically designed to endure such conditions. Corrosion resistance is a key factor contributing to the performance of steel sheets in marine environments. Typically, steel sheets are coated with zinc or other protective coatings like epoxy or galvanized coatings, which act as a barrier against corrosion. These coatings prevent direct contact between the steel and saltwater, reducing the risk of rust and deterioration. Moreover, the high strength of steel sheets makes them highly durable in marine environments. They can withstand harsh conditions such as waves, strong winds, and impact from debris. This strength ensures that steel sheets maintain their structural integrity and offer long-term performance. Furthermore, steel sheets are known for their fire resistance, which is crucial in marine environments where safety is a top concern. Steel has a high melting point and does not contribute to the spread of fire, making it a reliable choice for marine applications. Nevertheless, it is important to note that even with their excellent performance, steel sheets may still require regular maintenance and inspection in marine environments. This includes monitoring for signs of corrosion, repairing or replacing damaged coatings, and addressing any potential issues promptly to ensure continued performance. In conclusion, steel sheets are a reliable option for marine environments due to their corrosion resistance, high strength, and fire resistance. They can withstand the challenging conditions of saltwater, moisture, and impact, making them an ideal material for various marine applications.

- Q:Are steel sheets suitable for wastewater treatment facilities?

- Indeed, steel sheets prove to be a fitting option for wastewater treatment facilities. The advantages they present render them a commendable choice for this specific purpose. Primarily, steel sheets exhibit a high level of resistance against corrosion, a crucial characteristic in wastewater treatment facilities where the presence of harsh chemicals and corrosive substances is prevalent. This resistance to corrosion guarantees the long-lasting and durable nature of the steel sheets, consequently diminishing the costs associated with maintenance and replacement. Furthermore, steel sheets have the ability to endure elevated temperatures and pressure, rendering them suitable for a wide array of processes involved in wastewater treatment, including filtration and separation. Additionally, steel sheets possess the quality of being easy to clean and sanitize, an imperative factor in upholding hygiene standards in wastewater treatment facilities. They can be effortlessly washed and disinfected, effectively preventing the proliferation of bacteria and other harmful microorganisms. Lastly, steel sheets are environmentally friendly as they can be recycled, thereby reducing the environmental impact of wastewater treatment facilities. In conclusion, steel sheets offer the requisite strength, durability, and resistance to corrosion, making them an apt choice for wastewater treatment facilities.

- Q:What is the process of polishing steel sheets?

- The process of polishing steel sheets typically involves several stages such as grinding, sanding, buffing, and finishing. Initially, the steel sheets are carefully ground to remove any imperfections or surface irregularities. Subsequently, sanding is conducted using different grits of sandpaper to refine the surface further and achieve a smoother texture. Following sanding, buffing is performed using various polishing compounds and a rotating wheel or pad to bring out a shiny, reflective finish. Finally, the steel sheets are thoroughly cleaned and inspected before being considered polished and ready for use in various applications.

- Q:Are steel sheets suitable for playground equipment?

- Yes, steel sheets are suitable for playground equipment. Steel is a durable and strong material that can withstand heavy use and provide a safe environment for children to play. Steel sheets can be used to construct various playground equipment such as slides, climbing structures, and swing sets. Additionally, steel is resistant to weather conditions, making it a suitable choice for outdoor playgrounds. The material can be easily molded and shaped into different designs, allowing for creativity and customization in playground equipment. Overall, steel sheets are a reliable and long-lasting option for playground equipment, ensuring the safety and enjoyment of children.

- Q:How do steel sheets compare to glass sheets?

- Steel sheets and glass sheets have distinct properties that make them suitable for different applications. Steel sheets are known for their strength, durability, and resistance to corrosion, making them ideal for construction, automotive, and industrial purposes. On the other hand, glass sheets are transparent, allowing light to pass through, making them well-suited for windows, mirrors, and decorative elements. While steel sheets provide security and structural integrity, glass sheets offer aesthetics and visual appeal. Ultimately, the choice between steel and glass sheets depends on the specific requirements and intended use of the material.

- Q:Are steel sheets magnetic?

- Yes, steel sheets are magnetic.

- Q:Are the steel sheets resistant to vibration or shock?

- Steel sheets are generally resistant to vibration and shock due to their high strength and durability. Steel is known for its ability to withstand external forces like vibrations and shocks, thanks to its rigid nature. This allows steel to effectively absorb and distribute energy caused by vibrations or shocks, preventing any significant damage or deformation. In various industries, such as construction, automotive, and aerospace, steel sheets are commonly used because their resistance to vibrations and shocks is crucial. However, it's important to consider that the exact resistance of steel sheets to vibration or shock depends on factors like thickness, steel quality, and the specific magnitude and frequency of the vibrations or shocks.

- Q:Can steel sheets be laminated with other materials?

- Yes, steel sheets can be laminated with other materials. Lamination is a process of bonding two or more materials together to create a composite material with enhanced properties. In the case of steel sheets, they can be laminated with other materials such as plastics, polymers, wood, or even other metals. This process is commonly used to improve the strength, durability, corrosion resistance, or aesthetic appearance of steel sheets. Laminated steel sheets can be found in various industries, including automotive, construction, aerospace, and furniture manufacturing.

- Q:What are the benefits of using pre-painted steel sheets?

- There are several benefits to using pre-painted steel sheets in various applications. Firstly, pre-painted steel sheets offer enhanced durability and longevity compared to other materials. The paint coating on these sheets provides a protective barrier against corrosion, rust, and weathering, ensuring that the steel remains in excellent condition for an extended period of time. This makes pre-painted steel sheets ideal for outdoor use, where they are continuously exposed to harsh environmental conditions. Secondly, pre-painted steel sheets offer a wide range of color options and finishes, allowing for greater design flexibility. Whether it's for architectural purposes, interior decoration, or industrial applications, the availability of different colors and finishes enables the creation of aesthetically pleasing and visually appealing structures or products. Additionally, pre-painted steel sheets are easy to maintain and clean. The paint coating makes them resistant to stains, dirt, and grime, making them easier to keep clean and requiring less maintenance over time. This makes them an attractive choice for applications where cleanliness and hygiene are essential, such as in the food and beverage industry or healthcare facilities. Furthermore, pre-painted steel sheets are highly versatile and can be used in a wide range of industries and applications. From roofing and cladding to automotive parts, appliances, and furniture, pre-painted steel sheets provide a reliable and cost-effective solution for various purposes. They can be easily fabricated, cut, and formed into desired shapes and sizes, making them suitable for diverse manufacturing processes. Lastly, pre-painted steel sheets are environmentally friendly. The paint coatings used on these sheets are typically formulated to be low in volatile organic compounds (VOCs), reducing their impact on air quality and human health. Additionally, the durability and longevity of pre-painted steel sheets contribute to a longer lifespan, reducing the need for frequent replacements and minimizing waste. In conclusion, the benefits of using pre-painted steel sheets include enhanced durability, a wide range of design options, easy maintenance, versatility, and environmental friendliness. These advantages make pre-painted steel sheets a preferred choice for many industries and applications.

- Q:What are the different surface protection methods for steel sheets?

- There are several surface protection methods for steel sheets, including galvanizing, powder coating, painting, and epoxy coating. Galvanizing involves applying a layer of zinc to the steel surface to prevent corrosion. Powder coating is a process where a dry powder is applied electrostatically and then cured under heat, creating a durable and protective coating. Painting involves applying a liquid paint to the steel surface, providing a barrier against corrosion. Epoxy coating is a type of paint that is specially formulated with epoxy resins, offering excellent adhesion and chemical resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Zinc Coating Galvanized Corrugated Steel Iron Zinc Roof Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords