Zibo Factory Refractory Ceramic Fiber Blanket for EAF Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zibo Factory Refractory Ceramic Fiber Blanket for EAF Made In China

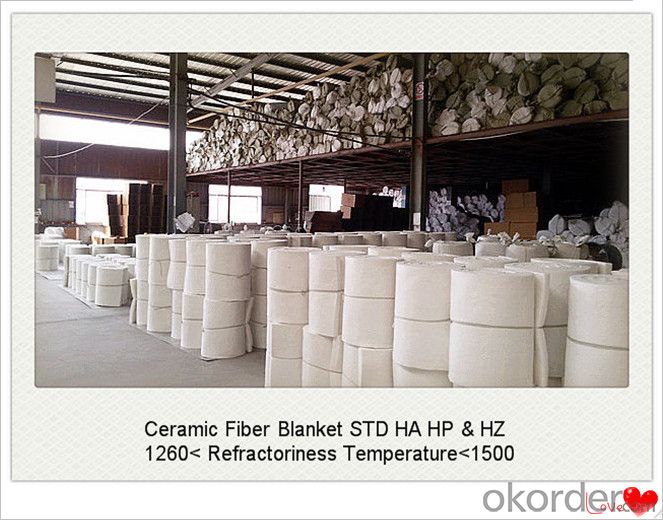

About Ceramic Fibre Blanket For Steel Factory

Ceramic Fibre blanket is ideal thermal insulation material, fire-proof material and sound-absorbing material. Ceramic fiber blanket has even texture and smooth surface.

Packaging & Delivery

Packaging Details:1.carton with inner PVC bags carton size:460*460*620mm 1*20FCL load 225cartons , 1*40FCL load450 cartons 1*40HC load 525 cartons 2.woven bags with inner PVC bags: 1*20 FCL load 225bags, 1*40 HC load 620bags

Delivery Detail:10-15 days after deposit

Characteristics of Ceramic Fibre Blanket For Steel Factory

1. low thermal conductivity ,low heat capacity

2. excellent heat stability and thermal shock resistance

3.good performance of thermal insulation, fire-proof and sound-absorbing

4. ultimate tensile strength

5. no delamination

Applications of Ceramic Fibre Blanket For Steel Factory

1.Industrial furnace, heating devices, high temperature pipe

2.High building fireproof ,sound-absorbing and thermal insulation material

3.Thermal insulation material for the electricity boilers, gas turbine and nuclear power.

4.Wall linings of the chemical high-temperature reaction equipment and heating equipment.

5.Thermal insulation for the furnace door and roof.

Images

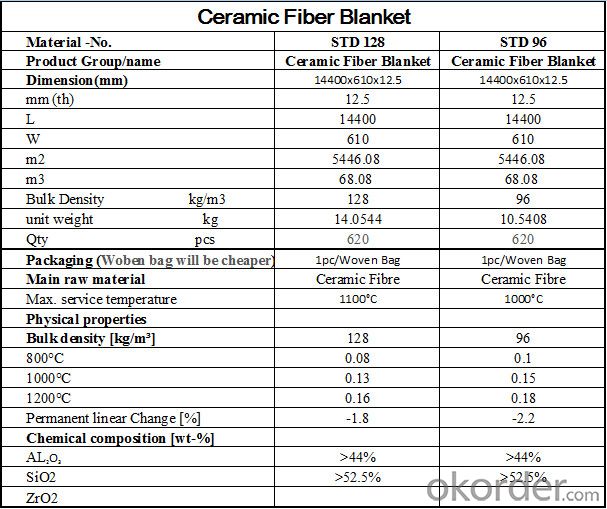

Technical data of Ceramic Fibre Blanket For Steel Factory

FAQ

Q1:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q2:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q3:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

- Q:what is the best kind of food to eat to fill you up.

- Take your hanger to the hardware and ask for some wire of that gaugeProbably a 16 or 14 will do.

- Q:ok so l8ly ive been under a ton of stress and stuffi lost a lot of weight, just a lot has been going on(i doNT hav an eating disorder or anything just fyi, its from the stress.) well i havent bee sleeping very good (about 40 hours that past weeks) i have been eating healthy and stuff, but idk i just feel like my energy level is at 0last week at cheer i almost got hurt bc i just couldnt find the energy to get my backhandspring and backtucks like i usually do, in other words i pretty much fell, wen im normally really good at themi have cheer in 2 hours, and i dont feel like my energy is very goodi have to go, long story, is there anything i can eat or drink to get energy? something healthy not like candy and sugarthanksim 14 btw.p.s please dont say 'you need to stay home and sleep' i have been doing my best to sleep everyday after school and i feel like i cant sleep its weird but yathank you for your time

- You absolutely can use your disposable aluminum trayOil it well with olive oil, and watch your crust, so it doesn't burn on you, since the aluminum is quite thin and doesn't heat evenly but can get very hot, unlike a thicker, dedicated pizza baking vesselEnjoy!

- Q:She seems to get bloated a lot and she doesn't have a bowel movement everydayAnd when she does, they smell abnormally bad and I'm afraid her digestive tract may be backed upI want to put her on a high fiber diet to get it movingAny suggestions on some high fiber foods I can regularly implement or any child friendly 'digestive tract cleansing' supplements?Thanks!PSPlease only give suggestions other than bring her to the doctorShe is already going todayBut I wanted to hear some first hand knowledge/suggestions from other moms and dads as well.Thanks!

- Give her a PBJ on wheat bread for lunchMy son lives on the basic sandwich, and it's healthy and fillingTry spinach with ranch to dip it in (All my kids loved it when there was something to dip stuff in) give her less juice and more waterCut out the juice completely if you canReplace it with fresh fruit - cut apple with peanut butter or cut up pearYou can cut it in baby blocks and make a little tower or think of other ways to make it interestingMy son and I will sometimes ding our orange slices in a toast before we have a who-can-eat-it-first raceAlways start any meal with the stuff you don't think she'll eat and don't let her see anything else for an hour.

- Q:i have really thick, frizzy, and poofy hair and i need a straightener that will leave it shiny and silkywhats the best kind? also it needs to be under 45 bucks thanks

- You save a lot, but it is a lot better using blown in fiberglass than celluloseFiberglass doesn't settle like cellulose doesIf you blow in twelve inches of fiberglass, ten years from now you will still have nearly twelve inches of material whereas with cellulose it will settle down to a lot less, so you need to add to it to save money again.

- Q:to make an adult blanketI want to use a super bulky yarn (lions brand home town) and a medium yarn togetherThe pattern would be: row 1- knit one, purl one until end of rowRow 2- purl one, knit one until end of rowRepeat rows one and two until desired length.Oh, and I will probably use size 19 needles.or do I need circular needles? Do you use circular the same way? Never tried them.Any help would be great.

- The best thing to do is to consult a doctorOr go to a pharmacy and ask for medicine to relieve constipationFor now, you should drink lots of water asap.

- Q:the hair im going to put on mine is yarnhow do it keep it onif i have to use glue what glue holds it on the best?????

- Hmm 98.6 is normal body tempYou should recheck thatMaybe you are getting a cold.

- Q:I Have made a list of materials that are at my disposal, but do not know what to do with themPlease Help!List:Paper, Pens/Pencils (colored/not), Shoe boxes, Tape, Candy, Eraser, Tech Deck, Trading Cards, Blankets/Clothing/Pillows, Toys, Suede Protector, Hats, Shoes, Broken Nook, Pencil Sharpener (Electric), Wooden Board, Yarn, Baseballs/Softballs, Mini Baseball Bats,Paintball stuff, Alarm Clock, Scissors, Myself.If you can, respond ASAP please! Thanks, Eddie

- Polishing Aluminum Fuel Tanks

- Q:Does anyone know of a type of yarn that won't break under stress ?? I weave and when I pull the yarn to make the warp I need to make it tight and most of time the yarn breaks :( Ive tried rug yarn before but it was too weakThank you in advance.

- Lining a baking pan with foil won't hurt your oven.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Zibo Factory Refractory Ceramic Fiber Blanket for EAF Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products