Z36 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

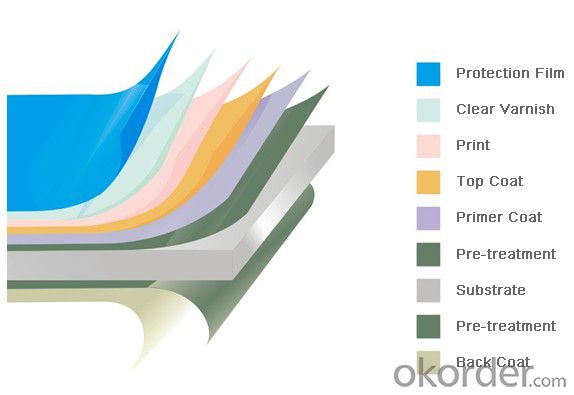

Structure of Z36 BMP Prepainted Rolled Steel Coil for Construction

Description of Z36 BMP Prepainted Rolled Steel Coil for Construction

Galvanized steel, galvanized steel coil, galvanized steel sheet, gi, gi coil, gi sheet, hdgi, hot dip galvanized steel coil, galvanized sheet, gi sheet price, zinc sheets, galvanized sheet metal prices, zincked sheet, galvanized strip, price of zinc sheets, zinc strip sheet, galvanized sheet metal fence panel, corrugated galvanized steel sheet, galvanized roofing sheet

Main Feature of Z36 BMP Prepainted Rolled Steel Coil for Construction

We have two production line of pre-painted steel coil And two lines for the galvanized steel coil, total yearly output is about 500000mt. In Order to meet our customers new requirements, We also can manufacture the special Products, such as Printed, Filmed, Pressed, Matte steel coil and the full hard G550 Galvanized steel and galvalume steel.

Applications of Z36 BMP PPGI Prepainted Rolled Steel Coil for Construction

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Z36 BMP Prepainted Rolled Steel Coil for Construction

Product | Z36 BMP Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Z36 BMP Prepainted Rolled Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q:What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

- Q:Is steel harder than iron or is iron harder than steel?Please explain... and help!Thanks

- steel is harder than iron Iron is a chemical element. It is a strong, hard, heavy gray metal. It is found in meteorites. Iron is also found combined in many mineral compounds in the earth's crust. Iron rusts easily and can be magnetized and is strongly attracted to magnets. It is used to make many things such as gates and railings. Iron is also used to make steel, an even harder and tougher metal compound. Steel is formed by treating molten (melted) iron with intense heat and mixing it (alloying) with carbon. Steel is used to make machines, cars, tools, knives, and many other things.

- Q:I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- Well, I know the water at this restaurants where they use metal pitchers taste a bit off to me. There's nothing wrong with the water, but I think the metal pitcher throws off the flavor. Could be the same with the metal bowl and the dog. Plastic is only a problem at hiding bacteria if it gets scratched up badly (which isn't as likely to happen with water as long as the dog doesn't chew it. You can also put the plastic crock bowls on the top shelf of a dishwasher for cleaning as the heat kills most germs.

- Q:What are the different types of steel finishes for coil protection?

- There are several different types of steel finishes for coil protection, including galvanized, aluminized, painted, and coated finishes.

- Q:How are steel coils used in the manufacturing of industrial valves?

- Steel coils are used in the manufacturing of industrial valves as they provide the necessary material for constructing the valve bodies and other components. The steel coils are processed and shaped into the desired form, ensuring the valves are durable and can withstand high pressure and temperature conditions.

- Q:I've seen on TV that stainless steel laminate sheets can be purchased and and used to cover appliances to give it a faux stainless steel look. They mentioned it was important to not have any bubbles (of course) and to work slowly. It's easy to do on a dishwasher, but what about the fridge? The handles are in the way? Do you have to take the handles off? Can anyone find a tutorial for me?

- There okorder appliance paint 2. What you are referring to really is not laminate steel sheets, it's actually more along the lines of shelf liner paper looks like steel with sticky back film that you peel and stick. Place against product and begin to peel down slowly using squeegee or credit card to smooth out bubbles.Sheets can be purchased rangingin size on OKorder for $9.99 + dependent on size. Called stainless steel appliance film can buy a roll for $60.00 on OKorder (normally sells for $100.00) one roll will cover 3 average sized kitchen appliances. Hope this helps!

- Q:How are steel coils used in the manufacturing of agricultural sprayers?

- Steel coils are used in the manufacturing of agricultural sprayers primarily for constructing the frames, supports, and structural components of the sprayers. The high strength and durability of steel make it suitable for withstanding the harsh conditions and heavy loads associated with agricultural operations.

- Q:Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their appearance, protect them from corrosion, and improve their durability. The paint or coating helps to create a barrier between the steel surface and the environment, preventing rust and extending the lifespan of the coils. Various methods and materials can be used for painting or coating steel coils, depending on the specific requirements and intended application.

- Q:I want to replace the old refrigator within the next 6 months........ Is the trend to buy a stainless steel refrigerator? Some magazines and internet sites are pointing me that direction. What are the pro's and con's ? I like the color bisque, or cream-color as well, or better, than stainless steel. What would be the reasons to buy stainless steel...is it becoming the most popular color ?

- I think it's just the popular choice at the moment like avocado green was the hottest thing in the 1970s. I bought a Whirlpool Sateen. It has the look of stainless steel, but magnets will stick to it. There is no functional difference.

- Q:is broken steel the only fallout dlc that will raise the level cap from 20 to 30? also do i have to complete the main quest to play it? which fallout dlc do you think would be the best to get?

- Yes, Broken Steel is the only DLC that raises your level cap. Yes, you have to complete the main quest to play it. It's kind of a prologue to the events of the ending. If you don't have the DLC and complete the game it just ends and you can't play it anymore. With the DLC you'll be able to continue playing. As for which one to get, that's your preference. Most people like the Broken Steel because it has to do with the main story and it raises the level cap - so that's the one I'll suggest to you. I also think The Pitt and Point Lookout are worth getting as well. Mothership Zeta is the one I liked least. I thought it was kind of stupid, to be honest. Operation Anchoarge is a simulation and it's pretty fun, but I don't think it's worth the $9.99.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Z36 BMP Prepainted Rolled Steel Coil for Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords