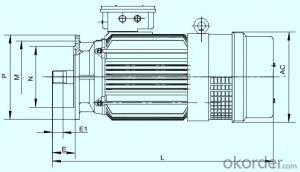

YTDVF Variable一Frequency Three一Phase Asynchronous Motor for Tower Crane Amplitude Mechanism

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview

the motor is a variable-frequency, three-phase asynchronous motor exclusively designed for the tower cranes and other similar amplitude mechanisms. It is applied to the

amplitude mechanisms in very harsh working conditions such as construction site or open pit quarry

Features

With introduction of spline output shat, it has good mechanical bearing capacity and excellent assembly performance;

Motor installation interface has the same size with original tower crane (POITAIN series), making it easier for switching and upgrading of old products

The motor is a variable-frequency motor featuring a wide range of speed regulation, small starting current, big starting torque and overload ability;

A thermal protection component is buried into the in stator winding and wired into the motor temperature protection control system, making motor more safer and reliable;

New brake (national utility model ZL201101881732, ZL201120188164.3) with higher safety and reliability this reduces the maintenance time and cost compact structure, small volume, lightweight as well as high reliability, so it can be braked quickly and positioned accurately. It is suitable for frequent starting and raking

- Q:I should have paid more attention in school physics lessons!

- Some countries in South America use Direct Current and if USA products are used there one must use transformers as you do here in the USA when using a battery oparated gadjet to a wall socket.This very Laptop I am using to communicate with you is battery operated and I have it plugged up to the wall to recharge as we speak(or type) and between the AC plug and my Laptop is a small rectangle that is transforming the AC current from the wall socket into DC current to the battery of the Laptop.

- Q:I have a 1/2 hp ac motor connected to a gear box it slows down when I put a paste product in a mill that I am using to produce some pellets, just want to know if I would be better off with a dc motor for more torque?

- Change it into a series motor that can take either AC or DC. Series motor provides maximum torque compare to other type of moter.

- Q:I've seen on facebook page of some technical institute that Tesla was NOT the first to build the AC motor, do you know who was first then?

- 3 PHASE synchronous motor was made first by Friedrich August Haselwander in 1887. 3 PHASE cage induction motor was built first by Michael Dolivo-Dobrowolsky in 1889

- Q:My AC stopped working a few months back, got the HVAC guy to come out and he said that the fan motor had gone out on one of the units (we have two) so he replaced it but ever since he did that , the AC will trip at the circuit almost everyday, sometimes a few times a day. When I looked at the old fan motor vs the new one, it looks as if the new one is higher HP 1/4 vs 1/6 and also more AMPs 1.8 vs the old at 1.0. or my other guess is that the shut of switch next to the ac units , one of them looks a little melted and the metal plate is slightly turned due to it. ( not sure if that is the correct name for it but it has a plastic handle that you can pull to shut of the AC unit right there). Any help would be appreciated. Thanks

- make sure he installed a new fan capacitor when he installed the new fan motor. The tech sounds like a hack if he replaced the motor with a different amps.

- Q:Why does the current in an AC Induction motor start to go up when the voltage is dropped off?

- Because the induction motor is a constant power device. If the voltage goes down, the current goes up to maintain constant power.

- Q:This is probably a really dumb question, but I have a motor that says SINGLE-PHASE 115 VAC @ 50/60 Hz on the side with two wires coming out of it. If I just wire it to a plug will it run on a 120V home circuit?

- The motor frame needs to be grounded for safety. This can be using the ground pin in a 3 wire cable and plug, plus the other two for active wires.

- Q:2003 Cadillac ext. can not control my blower motor on the ac?

- If the blower will only run on high, it's a bad resistor. If the blower doesn't run at all, it's a bad blower motor.

- Q:my group of hot rodders was sitting around the shop discussing building a electric car we are all looking for a plan next week we are meeting to discuss the plans we will be using when we draw up are cumulative ideas we will come up with the best ideas,hopefully. we are craftsmen at are hobby(lifestyle) but normally making a auto go fast 4 dollar gas has changed our thought pattern .if you have any ideas, with all your help my plans could be best. Thanks to all. lets get opec.

- I do not know of any electric vehicle that can go farther than 50miles before it needs to be recharged. The big draw back for this mode of transportation is the limited capacity of the batteries. This may be overcome within the next few years.

- Q:i have a 95 nissan oickup and i cant get the blower motor to work it works if i straight wire it but as soon as i put back n and hook up nothing the ac compresser still works fine just the blower ant blowin could it be the blower motor resistor

- Check fuses and relays.

- Q:My washer is acting up sometimes it will go into spin cycle sometimes it won't I have torn it down and can see the motor and can make the problem come back by cycling the lid (so the motor turns on and off until finally it doesn't come on again). The motors has 5 wires going to it. I put a multimeter on the two termianls that had 120 volts going to them and when I check continuity between the terminal and ground (case of the motor) there is one terminal that when the motor is working properly there is continuity but when the motor is 'stuck' there is no continuity.Does this mean the motor has a deadspot? What is the best way to diagnose if the motor is bad? which of the 5 wires should I check.The washer is WJSR2070B2WW

- May be a bad relay or the cycle motor has a short or gone bad

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YTDVF Variable一Frequency Three一Phase Asynchronous Motor for Tower Crane Amplitude Mechanism

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products