YR-4228 Full Automatic glass loading machine-Hot selling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

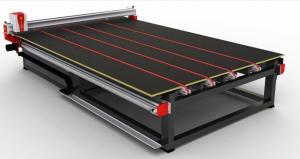

YR-4228 Full-automatic glass double-arm and single position loading machine

1. Description of Automatic Glass Loading Machine

The automatic loading & unloading system use variable frequency motor as drive source, to ensure smooth running and jitter-free. Transfer table uses chrome-plated shaft fitted with polyurethane wheel and synchronous belt. All main frame of equipment use Alufer welded and fitted with bolt. Electric control system of equipment use Schneider brand modules of electric; Program control uses imported SIMEINS programmable controller, fitted with touch panel.

Equipment System: main frame/ running system/ transfer system/vacuum adsorption system/mechanical turning system/high and low pressure control system/program control system.

Glass loading and unloading systems with suction cups.

2. Mechanical components:

1) turning wheel chain: high precision reinforced type

2) transfer idler wheel : PU

3) vacuum suction cup: double absorption structure

4) transfer/turning motor: Taiwan CPG motor

5) vacuum pump: PUXU( Sino-Germany)

3. Electric elements.

1) PLC controller: Delta

2) Transducer: Delta

3) Proximity switch: Swiss ELCO

4) Control cable: High-flexible shielded control cables

5) Contactor: Schneider

6) Pneumatic part: Taiwan Airtac

7) Pressure sensor: SMC

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:What are the types of automotive glass production lines?

- The joint venture with Shanghai Yaohua Pilkington (referred to as Shanghai yaopi, Shanghai Yaohua Pilkington and joint ventures, state-owned and listed companies), Wuhan Yaohua Pilkington (referred to as Wu yaopi, Shanghai Yaohua Pilkington and also with Wuhan local joint venture).

- Q:Problems in the mechanical processing of glass fiber reinforced plastics

- I think it is of little significance to use cutting fluid when machining frp. Because the heat of cutting is not enough, air cooling can satisfy. But there will be an environmental problem - dust flying, which is harmful to people when they are sucked in. Therefore, we used to buy a set of industrial vacuum cleaners, processing machine parts (work stations) partially closed, operators with industrial masks, quite troublesome. Have also tried to dial a special machine (milling machine) to make glass fiber reinforced plastic products. With coolant, the chip separation mechanism is specially made, which is similar to the filter of grinding machine.

- Q:What kind of equipment does the toughened glass production line include?

- Auxiliary equipment: glass cutting edge grinding machine punching machine cleaning machine

- Q:Glass mechanical grinding, grinding wheel mesh 180, belonging to the grinding edge? What is the appearance quality?

- 180 the glass of the grinding wheel of the target wheel must be opaque and visible. A washing forming section, visible grinding machine, wheel configuration: No. 1, wheel 180*, No. 2, wheel 300*, wheel 3, 400--500, 2 sets of polishing wheels (resin wheel)After tempering glass is generally not recommended for grinding 1. first in the process of grinding wheel 1, adjust properly it will break the glass and the conveyor belt are likely to scrap (we will destroy the 2 synchronous belt 2.) after tempering grinding will damage much toughened glass compressive stress layer after grinding blew the chance increased

- Q:What kinds of equipment are there in FRP production facilities?

- Paving equipment - use under special circumstances.Proportional coating equipment - if there are a number of components, heat it up in the heating molding equipment after gluing.

- Q:How do we polish the plexiglass after processing?

- Edelweiss DX it depends on your final transparency, I used to use when PC resin is first with 200 to 400 change to rough polishing, fine polishing. Transparency is ok.

- Q:How do you make plexiglass?

- Plexiglass processing is very simple, and can be processed with woodworking machines. Only use plexiglass for cutting tools and saw blades. The main machines are: material saw, planer, gongs machine, profiling machine, engraving machine, laser cutting machine, polishing machine, polishing machine, and so on.

- Q:What kind of cutting fluid is used in organic glass processing?

- SCC790 glass cutting fluid is a high-grade, glass and ceramic special synthetic glass grinding fluid, diluted with water to form a clear, transparent yellow solution.

- Q:How much does a set of insulating glass aluminum strips require?

- Look at your finances. If you want a vertical one, it's more expensiveIf it is ordinary, two machines can be about 3W

- Q:Where there is a machine for processing glass, that is, you can empty an empty wine bottle into a crystal, or a bead

- Without doing so, there can be no gains! The amount of grinding is too great, the products are not enough emery money, do not say money, wages, utilities, have to paste.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YR-4228 Full Automatic glass loading machine-Hot selling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products