YR-4228 Full Automatic glass cutting line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 45 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

YR-4228 full automatic CNC glass cutting machine

Product General Description

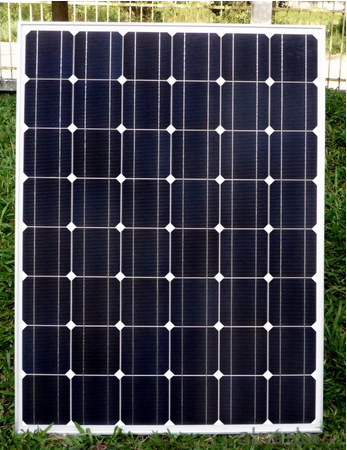

A photovoltaic (in short PV) module is a packaged, connected assembly of typically 6×10 solar cells. Solar Photovoltaic panels constitute the solar array of a photovoltaic system that generates and supplies solar electricityin commercial and residential applications. Each module is rated by its DC output power under standard test conditions, and typically ranges from 100 to 365 watts. The efficiency of a module determines the area of a module given the same rated output – an 8% efficient 230 watt module will have twice the area of a 16% efficient 230 watt module. There are a few solar panels available that are exceeding 19% efficiency. A single solar module can produce only a limited amount of power; most installations contain multiple modules. A photovoltaic system typically includes a panel or an array of solar modules, a solar inverter, and sometimes a battery and/or solar tracker and interconnection wiring.

Physical characteristic

Equipment frame: guarantee accuracy and keep the shape.

Cutting tool apron: cutting head can rotate 360 degree.

Table top: HDF board

Felt: imported felt, smooth and anti-static

Cutting oil: pneumatic input oil automatically, cutting and oil synchronization

Transfer system: Synchronized belt transfer automatically.

Mechanical parts

Table top: HDF board

Rack: KHK

Transfer belt: Barbieri

Cutting wheel: Germany Bohle

Electrical parts

Microsoft windows interface

Voltage: 380V/50HZ, equipped with transformer.

Motor: Japan YASKAWA sever motor

Approach switch: Switzerland ELCO

Control card: Italy imported TECNOS (match with Italy OPTIMA SOFTWARE)

Main electrical parts: Japan IDEC Relay, Schneider A. C. Contactor

Air proportional valve: Japan SMC

Calculate capacity automatically

- Q:What equipment do you need to produce glasses? Is the process complicated? Are there many raw materials?

- The main raw materials for glass production are glass forming bodies, glass adjusting materials and glass intermediates, and the rest are auxiliary raw materials. The main raw materials, intermediate oxide and oxide to network oxides into the glass forming network; auxiliary materials including clarifying agent, fluxing agent, emulsifying agent, coloring agent, bleaching agent, oxidizing agent and reducing agent etc..

- Q:I'd like to open an art glass processing factory. What equipment do I need?

- Find a glass art processing factory to work for a period of time, process and equipment do not know, the enemy can ever victorious, I also want to do glass processing technology, but no money, can only think of.

- Q:What are the plexiglass processing equipment?

- There are casting equipment, as well as cracking monomer recovery equipment, I do not know what you use to do. And how big is your equipment?

- Q:Do you use UV flatbed printers for glass processing?

- Converted to A4, A3, A2, A1, with 9880, 7880, 4880, 1900 and other modifications, unstable, less than 2 months scrapped, priced at between 1-4 million. The printing speed of 0.3-1.5 M / h. 6090uv printer, printing format 60cm90cm, double DX5 nozzle, the price 5.5w. The printing speed is 2-6 square meters / hour, high precision equipment business.

- Q:What are the mechanical equipments of float glass production line?

- Finished processing line: glass plate after annealing with continuous processing into the finished product line, through the shower water washing, drying, scanning, detection, slitting, cutting, breaking, and go to the side, according to different dimensions, and then by fetching device, automatic film fetching, stacking and packing paper. The cut edge and unqualified glass are broken and sent to the broken glass system by belt conveyor.

- Q:Method for making organic glass

- Paste methodCut the plexiglass into a definite shape and paste it on the surface.

- Q:How much money do you need to invest in making glass hot bending? What equipment should I buy?

- Buy finished five to hundreds of thousands of glass grinding machine and cleaning machine around sixty thousand yuan, if the initial investment of one hundred thousand yuan or so, do not count the current funds

- Q:How much does a set of insulating glass aluminum strips require?

- How do I want to do aluminum bars, this depends on the amount of money, there is no good market, it is best not to do.

- Q:Can the recycled waste glass be re processed into glass containers (such as beverage bottles, etc.)?

- In fact, most glass is pulled back to the glass plant after the smelter is made into float glass.

- Q:Organic glass (PMMA) hole thread processing, how to eliminate burr? Urgent!

- Organic glass is a popular name, abbreviated as PMMA. The chemical name of this polymer transparent material is called polymethyl methacrylate. It is a polymer compound made up of methyl methacrylate. It is a kind of important thermoplastic plastics which have been developed earlier.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YR-4228 Full Automatic glass cutting line

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 45 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products