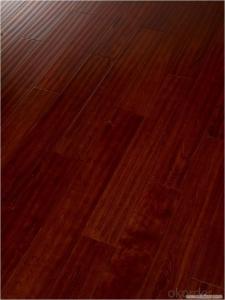

Yongsen Indoor Matt Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Material properties

Diffuse porous wood, heartwood and sapwood yellowish white, the difference is not obvious. Sapwood pale. Growth wheel is not obvious. The tube hole is slightly under the naked eye, and the number is small, and the body is slightly larger. The axial parenchyma tissue is not visible under the naked eye, and the magnifying glass is obvious. Wood ray magnifying glass is obvious. No ripple and intercellular canal.

Wood with a gloss, no special smell and taste, straight texture, fine structure, even a little; weight of wood basic density 0.49g/cm3, air dry density 0.59 g / cm3), dry shrinkage, moderate intensity. Wood drying performance is good, fast drying, cracking, deformation is small; the poor resistance to corrosion, preservative, good performance. Wood sawing, planing and other processing easy, smooth surface, good adhesive properties.

2、Product Characteristic

Advantages: paint is soft, and not dazzling, floor slightly flaw can not see, a long time often go to the place and go a little place is not obvious.

3、Parameter

Material: fiber skin jade

Origin: Zhejiang

Style: Modern

Standard: ISO90001

Applicable scope: bedroom

Pattern: Wood

Special purpose: wear resistant

Plate finish: good

Surface shape: paint

Residual depression: no

Formaldehyde release rate: E1

Resistance: good

Wear layer thickness: 3cm

Abrasion resistance: good

Fading (stage):1

Floor thickness: 18mm

Colors: yellow, red

Specifications: 910*115*18

4、Reference pictures

- Q:And where's the best place to shop for either hardwood floor in Toronto?

- Solid hardwood requires special tools to install and most likely will require a professional installer. With click engineered floating floors, less specialized tools are required for installation, making it easier for the do-it-yourselfer.

- Q:I have engineered wood flooring glued to a slab on grade sub floor. We want to remove this and install a thin profile (that is rated and acceptable for concrete sub floor installation) hardwood flooring. However, the cost and hassle to remove the existing engineered wood flooring is more than the new hardwood itself. Could I simply add an additional layer of plywood on top of the existing engineered hardwood (to get the correct height for nails) and treat this as my sub floor, ready for new installation?

- How old is the building your living in. That could give you a clue if they are hardwood. If the building is 50 years old or more then it's a good chance that they are hardwood. You can buy hardwood flooring cleaner at Home Depot. Check out the seams where the flooring butts together. If you are able to visibly see and or slide something very thin into the seam like a razor blade then it's hardwood if not then it's most likely laminate.

- Q:All my boards are in 3ft lengths. Do I need to cut them to various lengths before starting? What lengths should I cut them in? Does it look weird having a 3ft borad then a 8 inch board? Please help!

- If you don't want glue(Chemicals,formaldehyde)in the house you can use a rubber membrane on top of the concrete beneath the wood. It will give you a more solid floor than just floating it.Home depot has a product its a green roll membrane.

- Q:Can I use Liquid nails (subfloor or HD) to glue down 3/8 thick engineered hardwood flooring? If so what are the disadvantages vs urethane flooring glue? And if not, why? The manufacturer's directions say the floor can be installed over wood sub flooring via nailed, glued or floating (with glued joints). Urethane flooring glue runs $40 per gallon/(40sq ft) at both Lowes and Home depot. Liquid nails would be much cheaper and simple to use. The room is small at only 130sq ft. thanks

- Liquid Nails Subfloor

- Q:The home with linpai white oak flooring, usually used in the study, was half a year down IKEA's wheel chair chair went on the ground found there have been many small pits, the surface of this one area is not so bright. Don't know is not suitable for soft wood or roller, and remedy measures?

- The renovation of the floor is the floor surface for grinding, putty, paint, polishing wax, to restore the old floor light, prolong the service life, as follows:1: the floor of the grinding, grinding machine should be used in turn 40 and 80 mesh and 120 sandpaper (mesh is larger, the smaller the particle sand paper burnish leaves, the scratch is not obvious) grinding three times, then the putty leveling floor, then to the floor paint or color processing. Because the texture of the wood surface is natural, can not change the color, can only adjust the depth of the floor color.2: re painting, the general need to brush the floor primer, two finish. If the surface after polishing the floor there are flaws, it is necessary to brush the paint several times according to the situation. Once the paint is completely dry before brushing the paint again. So the floor renovation generally takes 4 days.

- Q:We bought a house with engineered oak hardwood floors that look to be 3mm thick. We're trying to determine if we can refinish them or if we just need to replace them, but we're not sure how to tell if they have am aluminum oxide finish. Is there a way to tell without knowing the manufacturer or any other related info?

- Not so much, no. There's no test that you can do at home that can tell you if these engineered floors have an aluminum oxide finish or another type of modern finish. But unfortunately, chances are it's AO. Most engineered floors, especially those that aren't super expensive (so floors bought through THD and etc.) are AO.

- Q:Can anyone tell me the best quality engineered hardwood flooring. We have two energetic dogs who wrestle a lot. If you have any experience please respond. Thank you

- Your aluminum oxide finish ( available on most prefinished wood now )is one of the tougher coats now .. I haven t heard of many scratching complaints. Keeping their nails trimmed is always a big help. GL

- Q:What is the difference between laminate flooring and ten solid wood flooring

- How to choose a good home:Choose the floor according to their actual situation, the following to introduce you to some of the knowledge of the floor.Classification of composite flooringCurrently on the market there are two main types of composite floors: one is a solid wood composite floor; the other is to strengthen the composite floor. These two types of composite floor has its own different characteristics, in the use and maintenance requirements are also different.

- Q:Im getting ready to install Pergo engineered hard wood floors. It is going to lay over concrete floor. What is the diffrence between floating it or glue down. Whats better?

- pergo is not installed with glue so your answer is right there it is installed over a pad

- Q:I dont have a way to measure the thickness of the top layer but can you tell from this picture? and can this be sanded? My dogs have destroyed the surface and I'd like to refinish it when I put the house up for sale.

- If your floor is TRULY engineered flooring and not laminate then the other answers are incorrect. Engineered flooring has a thin layer of wood (1/4 or less) bonded to a manufactured substrate. You CAN lightly sand it at least one time to remove light wear and superficial scratches. But if it is deeply damaged you will be out of luck. It is impossible to tell from the poor photos you posted what you actually have so I would recommend that you call a professional flooring refinisher to evaluate what might be possible in your case. Don't try sanding it yourself. It looks like you have some scraps of it in the photos. Take some medium grade sandpaper and try sanding the scraps deeply and see what happens. If it is laminate the woodgrain finish will vanish with very little sanding. If it is wood you will get some fine sawdust and the grain will continue in the lower layer. Again, the job is one for a pro, not yourself. In fact, your photos look more like laminate so this may be an impossible project from the get go. Why do you believe it is an engineered floor? Did you have it installed yourself?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Yongsen Indoor Matt Solid Wood Floor

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products