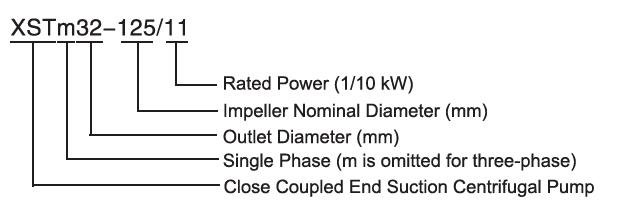

XST Series End Suction Centrifugal Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Our water pump had a leak in one of the pipes which kept making us Los the prime. I've replace the piping so it no longer leaking but I can't get I to work. The pump runs but the water doesn't move-. The pressure says it is at 50 but nothing. Also its a sahllow well pump jut bought last sprig.Any ideas? Sorry for the bad grammar new to this tablet.

- The pressure says it is at 50 which means there is water at that point or you have a faulty gage(happens all the time with those gages). Replace the gage and then you can determine if the pump is pumping and if there is a clog after that point in your line, which is actually quite common when one works on these systems., if it isn't pumping, could be a bad foot valve, pump, well ran dry, needs to be primed, ect...

- Q:Why can't sprinkler system and hydrant system share water pump in fire fighting system?

- The design code of sprinkler system GB 50084 - 2001 (2005 Edition) stipulates that the sprinkler system shall be provided with an independent water supply pump, that is, the water pump shall not be shared with the hydrant system. The aim is to ensure the reliability of the water supply and prevent interference.See the code for design of automatic sprinkler system, GB 50084 - 2001 (2005 Edition), 10.2.1 and the corresponding provisions of the following interpretation.

- Q:Can someone please post a picture of how to find a Water Pump on a 1992 Dodge Spirit with a K2.5L Engine, it would be much appreciated. :)

- not a bad idea to post your question in the boating section, considering that us boaters are smarter than most, but you'll probably have a better chance of resolving your problem if you post it in the automotive repair section.

- Q:How can I be sure the water pump is the problem before spending $ on repairs. 97 civic overheating.?

- i can't b sure 1 replace thermostate 2 same time reverse flush with good chemical,,,entire system 3 you got to realise after 13 yrs original radiator may be gone,,,water pump gone for sure,,,hoses cant last over 6/8 yrs; 4 other things,,,tuned up,,,bad running will heat it up ,,,,50/50 coolant/water...clean and full

- Q:i want to change the water pump on my on a 70 hp (70C) nissan outboard motor and i never pulled a lower unit, not sure what to expect thanks for any help

- hi you need to get the workshop manual for your motor. You can go to the library I am sure they will have one. The basics though... make sure you have a lower unit gaskey set, a full water pump rebuild kit and the correct impellor. You need the manual so that you can locate the correct bolts to loosen and the procedure for disconecting the gear shifting mechanism. With the manual its an easy job. without.. its kind of pot luck if you have never done it before. I have changed impellors and water pumps on many different boat motors and i have aways used the manuals. Even now I would still use the manual as a reference to change the impellor and water pump housing in my Johnson even though i have done it before. The manual will probily cost about $25 but it will save you hundreds in the long run as you will be able to trouble shoot other problems.

- Q:I have a 1995 Jeep Grand Cherokee 6 cyl while driving home the other day my check engine light came on ,then I noticed my battery was loosing its' charge ,then I noticed my temperature gauge rising very fast.I stoped to see what the problem was.The vehicle had over heated and the serpentine belt was partially off Iet it cool down then I put water in it and drove it home which was about a quarter of a mile.I noticed no problems with the fan hitting the water pump pully until I put the belt back on .My water pump pulley appears to be off line how do I fix this?

- your water pump bearing is probably worn out, unfortunately if this is the case replacing the water pump is the only option take the belt off again grab the fan if you can wiggle it forward and back its no good if its ok go to the belt tensioner, Its the next most likely culprit if it get out of line it will throw the whole thing out of whack good luck

- Q:We have an electric sump pump. Battery pumps will only work for two or three days. I want a manual pump that will pump a lot of water. We cannot waterproof the basement because it costs over $10,000. Where can I find a manual pump? Carrying water out in buckets is too slow and exhausting. We carried 80 five gallon buckets out last time the electricity was off for a few hours.

- There okorder ... They are typically installed as back up to the electric powered one and will only come on when the electric has failed. they use a siphon action that is supplied by water flowing through a pipe so they use a lot of water but as long as your house has water pressure they will keep the basement dry. When the electricity comes back on they shut off because their float switch is activated at a higher level that the electric ones.

- Q:If there were no water at the discharge of a pump and then you had just fed water through and measured the pressure of the gauge...would that be a different pressure if the whole system (both inlet and outlet) were continuously filled with water?

- 1.If there is no water at the discharge of the pump then there can be no pressure. 2. If there is water at the discharge of the pump, but the pump is not running, then there will be a pressure in the system. 3. If the pump is running, the pressure in the system will be higher than at 2.) above becuse it takes additional pressure to move the water through the piping. The flowing water requires additional pressure to get thru the piping system.

- Q:The water pump in my 2001 PT Cruiser needs to be replaced and I'm wondering how much I'm looking at. I know it would vary and I know it's supposed to be labor-intensive but I thought I'd ask on here before I call my mechanic. We are trying to figure out if we should just go ahead and look at getting a new car. Thanks for any help!

- JUST HAD MINE DONE. FINAL COST $750. LABOR INTENSIVE OVER $400 IN LABOR AT $48 AN HOUR.GOOD LUCK

- Q:replaced water pump and thermostat, flushed, opened bleeder valve had long life red colored original coolant, no visible leaks obstruction, when became hot on highway, accelerated quickly and temp back down to norm, eventually after 3hrs driving o.heated stopped and got towed home, new water pumps fins/pulley not turning as freely as old one, no leak out of inspection hole, hoses good shape.2001 2.2l ohv sunfire, air cond.

- Check the bearings on the pulley / pack some grease in there. Hope some help !

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

XST Series End Suction Centrifugal Pump

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords