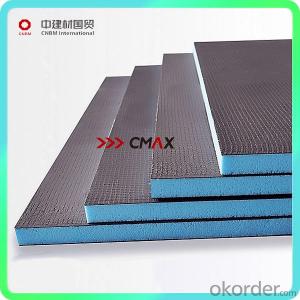

XPS Extruded Polystyrene board,XPS Insulation board, Styrofoam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | xps 250 | Thickness: | 25mm-60mm | Color: | Light yellow / Blue /Green |

| Width: | 600mm / 1200mm | Length: | 1200mm-3000mm(or any) | Edge Shape: | SL SS T&G |

| Surface: | Withskin / Roughing / Embossing |

Packaging & Delivery

| Packaging Detail: | Poly Bag |

| Delivery Detail: | 5-15 Working days |

Specifications

XPS extruded polystyrene board,XPS Insulation board, Styrofoam

1. Without any CFC/HCFC/HFC

2. Eco-friendly

3.25mm-50mm

Feininger XPS Foam Board:

XPS extruded polystyrene board,XPS Insulation board, Styrofoam

Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

Lightweight: volume optimization and easy to handle

Resistance to deformation

Resistance to impact

Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape

100% ozone friendlyRecyclable: Polyfoam can be 100% recyclied

Technical Data Sheet:

Item | Unit | Property Index | |||||||||||

With Skins | |||||||||||||

X150 | X200 | X250 | X300 | X350 | X400 | X450 | X500 | ||||||

Compressive Strength | KPA | ≥150 | ≥200 | ≥250 | ≥300 | ≥350 | ≥400 | ≥450 | ≥500 | ||||

Water Absorption, | %(by volume) | ≤1.5 | ≤1.0 | ||||||||||

dipped in water for 96h | |||||||||||||

Moisture Permeability, 23°C±1°C,RH 50%±5% | Ng/(m.s.Pa) | ≤3.5 | ≤3.0 | ≤2.0 | |||||||||

Heat Insulation | Heat Resistance Thickness25mm 10°C 25°C | (m2·K)/W | ≥0.89 ≥0.83 | ≥0.93 ≥0.86 | |||||||||

Heat Conductivity Average Temp. 10°C 25°C | W/(m·K) | ≤0.028 ≤0.030 | ≤0.027 ≤0.029 | ||||||||||

DimensionalStability 70°C±2°C, 48h | % | ≤2.0 | ≤1.5 | ≤1.0 | |||||||||

- Q:How to distinguish between good and bad insulation board insulation board

- Class flexible management refers to the class teacher in the student's psychological and behavioral laws on the basis of the use of non-mandatory way, in the minds of students to produce a potential persuasive, the use of the class teacher's own positive factors to influence and guide students

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- Use the wall connection, set the location, the number of construction sites in accordance with the development of specific programs to determine. But also must meet the "construction of fastener type steel pipe scaffolding safety technical specifications JGJ130-20 lack of reminders of the United States and the United States and the United States and the United States and the United States and the United States, Note: . different erection mode, different height, the vertical spacing, horizontal spacing, each wall with a specific coverage area requirements. . pay attention to the standard is JGJ130-. do not use JGJ130-2002 old standard, the old and new standards on the wall with a little different provisions.

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- The key indicator of good or bad weight is the weight, that is, the weight per cubic meter. Big enough.

- Q:Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Metal hose is an important connection in engineering technology, from the corrugated flexible tube, mesh sets and joints combined. China in 1993 issued a national standard "corrugated metal hose general technical conditions" (GB / T-93). Metal hoses are made of austenitic stainless steel or according to the material required by the user. It has excellent softness, corrosion resistance, high temperature resistance (-235 ℃ ~ + 450 ℃), High pressure (up to 32MPa), in the pipeline can be connected in any direction for temperature compensation and absorption of vibration, reduce noise, change the direction of media transmission, to eliminate the pipe or between the pipe and mechanical displacement between equipment, Lan metal corrugated hose for a displacement, vibration of the various pumps, valves and other flexible joints is particularly applicable. Metal hoses use two kinds of bellows, one is a spiral corrugated tube; the other is a ring bellows. Spiral bellows The spiral bellows is a tubular shell with a corrugated spiral and has a helix angle between adjacent two corrugations. All corrugations can be connected by a helix. Ring bellows Corrugated tube is corrugated closed ring shaped tubular shell, wave and wave from the ring ripple in series. The ring bellows is machined from a seamless pipe or welded pipe. By the processing mode, compared with the spiral corrugated pipe, the length of a single tube is usually shorter. The advantage of the ring bellows is good elasticity and small rigidity. If you need to provide detailed advice, please call 0317-, Xinlong bellows will be happy to serve you.

- Q:The traditional ceramic insulation board, the existing thermal insulation coating in addition to the process and the construction period there are similarities and differences there are differences? Which energy-saving building is better?

- Because the middle of the lap will lead to fasteners, fasteners can not withstand such a large force, and the top can withstand

- Q:Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- Flexible waterproof casing for Shanghai Geng high international 薨 uan arm for the seismic fortification requirements of the area, the pipeline through the walls to withstand vibration and pipe telescopic deformation, or a strict waterproof requirements of the building (building) buildings

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- 25 thick extruded polystyrene plastic insulation board 35kg / m3

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- Flexible ducts for rigid piping and ducts for gas pipelines for drainage pipes

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q:25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- 2 fastener type steel pipe stent construction must be prepared before the construction program

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

XPS Extruded Polystyrene board,XPS Insulation board, Styrofoam

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords