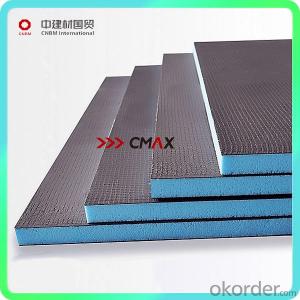

XPS Extruded Polystyrene board for factory workshop with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | 1200 | Density: | 30-50kg/m3 | Compressive strength: | 150kpa-900kpa |

| Material: | polystyrene resin | Highest Working Temperature: | 75° | Heat conductivity: | 0.028w/m.k |

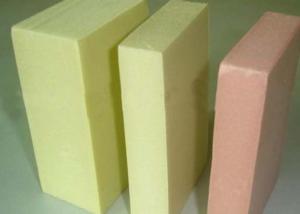

| Water absorption: | <0.3%< p=""> | Normal color: | pink,red,grey and blue |

Packaging & Delivery

| Packaging Detail: | PE film bag |

| Delivery Detail: | 15 days |

Specifications

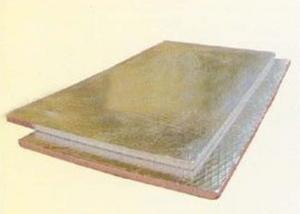

our xps sandwich panel is low water absorption,high hardness,good anti-corrosion and high-quality enviormental protection

High quality XPS extruded polystyrene board for factory workshop

XPS main Character

Low water absorption,high hardness,good anti-corrosion,long life-used and high-quality enviormental protection.

The raw material is polystyrene foam, which is formed by extrusion molding.

Brief Description

1. customization can be discussed

2. general thickness :available from 10mm to 70mm(special for 80mm120mm)

3. width: :available from 450mm to 1200mm

4. length: available from 1200mm to 1300mm

5. general density :available from 32kg to 50kg per cubic meter,

6. thermal conductivity :0.028w/mk

7. oxygen index:28

8. compressive strength:150kpa to 900kpa

9. water absorption:<0.3%< p="">

Certifications

CE certificate;GBT2800-2001;ISO2008-2001;ISO14001-2004

- Q:How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Air-conditioned room can not have flammable gas, in order to avoid explosion and fire do not frequent switch air conditioner, because the compressor starts when the current is running a lot of times the current, easy to burn the compressor motor 3) Do not put things on the outdoor unit of the air conditioner to avoid air conditioning noise. It is a great persecution for the air conditioner. The temperature of the general air conditioner is adjusted to 26 ° C to 28 ° C. , To avoid excessive power consumption next to the air conditioner must not be twitching Fengqi gong bite astringent ax to have a high temperature heat source, so as not to heat the panel deformation

- Q:What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q:How to distinguish between good and bad insulation board insulation board

- Your main source of high temperature in the room is the west of the glass and the south of the window you can in the west and south from the glass 20_50 cm hanging curtains so much of the heat was blocked the roof available 60 * 60 gypsum board ceiling that Economic effect and good ceiling 15-18 yuan per square

- Q:Steel structure rock wool sandwich wall panel what the amount of this set

- Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The First play expansion bolts, do insulation, can say the details of the point. There is that you can use .7 inside the expansion of the screw, to Fu Fu Huang Peng, You can also use welding, then a long screw, is also very simple.

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- Think of the safety data directory to compare the trouble to compare JGJ59-2011 check the information bar

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- The interior design of the ceiling, to determine the location of the tuyere, and then design the HVAC professional with the design, after the design, you will find some outlet can not be arranged, or the ceiling must increase the outlet, and then install the factory twisted class defended straight gambling astringent leopard Adjusting the ceiling to adjust the drawings. In other words, this is the process of two professional cooperation with each other, but mainly based on the decoration ceiling map.

- Q:Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q:25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q:Sound insulation and polystyrene insulation board which sound insulation better?

- Can be considered ultra-fine inorganic fiber spraying, this insulation material is sprayed up, not limited by the shape of the building, the speed is still fast

- Q:Why extruded board (XPS board) is the best insulation board material

- Rong Sheng this section is quite good, the appearance of fashion, quiet, energy saving, computer temperature control, insulation effect is good

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

XPS Extruded Polystyrene board for factory workshop with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords