X-over sub for for conversion and connection of drill stem component in petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Xover sub acts for conversion and connection of drill stem component in petroleum, natural gas and geology drilling work. It is one of the main tools in connect the upper tool and the bottom Hole. It is used mainly for connecting of upper drill tools and lower drill tools during drilling operations when upper and lower buckle type failed to connect during drilling operation.

2.Features:

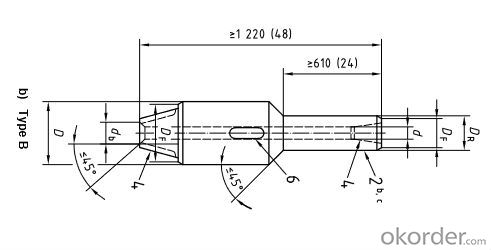

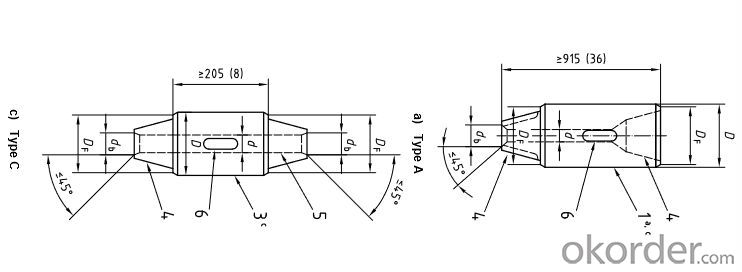

3. The basic structure of the X-over sub

Variety | name

| Upper link

| Lower link

| Type

|

1 |

| Kelly

| Drill pipe joints

| A or B A或B |

2 | drill pipe Cross-over sub

| Drill pipe joints

| Drill pipe joints

| A or B A或B |

3 | Transition Cross-over sub | Drill pipe joints

| drill collar

| A or B A或B |

4 | drill collar Cross-over sub

| drill collar

| drill collar

| A or B A或B |

5 | Borehole Cross-over sub

| drill collar

| drill collar

| A or B A或B |

6 | Faucet Cross-over sub

| Faucet

| Kelly bar

| C A或B |

7 | Salvaging Cross-over sub

| Kelly

|

| C

|

Drill pipe joints

| Fishing Tools

| C |

4.Pictures

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:I need regular manufacturers' agents (with authorized certificates and large scale agents)

- I am Nanjing Yi million strong bearing Co., Ltd. (Jiangyin Office)I am mainly responsible for regional sales in Jiangyin, Zhangjiagang, Jingjiang and so onWe are regular dealers. Here are our certificate of authorization.

- Q:Bearings into the sand, to dismantle the wheel, there are other ways?

- If the bearings are not replaced, the bearings can be cleaned by kerosene, and then the grease is sealed again.

- Q:Yoyo how can I wash the bearings without gas?. What other materials can I use?

- Thinner, acetone, chloroform, banana water, kerosene.

- Q:where can I buy other GPS drilling accessories? I have some GPS rigs.

- With so many rigs, you can buy it directly from Wuhan Jintai Geological Engineering Machinery Co., ltd.... They have all rig accessories, very, very complete. You can call them 400

- Q:What model is used more? What are the prospects for development? Does the price have an advantage?

- There are many manufacturers of this kind of bearings, mostly in ShandongShandong bearing price is very strong, quality is guaranteedInterested, contact information to see personal data

- Q:A winter hand is out of the question, always pull the beginning of a circle when no problem, after feeling a little strength are not, pay attention to the following 2: 1, the legend of the hand is slipping should take a one-way bearing cleaning, I remove the bubble in alcohol and with ultrasonic cleaner washing, the result is really good for a moment, the next is not good; also for the one-way bearing, when the hammer is likely to change in the same phenomenon. 2, this is a method I find, is the first at home to the engine oil pump, the pump to the obvious rich and even a little bit when misfire, hand is good, get out after the fire down soon start pouring fuel, normally is not a one-way bearing can not enter fuel? Late into the fuel hand puller is obviously not slip like a long time don't see is what reason, solution!

- Is the quality of bearings, the size is not standard, because the axis tolerances are limited, resulting in a loose tight. Replace the bearings of better quality.In principle, the general transition fit, one-way needle, this structure is too simple, and the accuracy is not high, the domestic small factory product quality is not stable.A one-way bearing is a type of bearing that can be turned freely in one direction and locked in another direction. One-way bearings, also known as overrunning clutch, but according to different industries, the role of different naming.

- Q:What's the bearing fillet of the 7003C? Do other bearings have the same fillet?

- The other bearings don't have the same fillet, and the bigger the bearing, the bigger the fillet.

- Q:FAG bidirectional thrust angular contact bearing 234416M.SP can be replaced by other manufacturers?

- Japan NSK Code: 80TAC20XLJapan NTN code name: 562016SKF code name: 234416TN9/SPDomestic HRB Code: new code name: 234416. Old code name: 2268116

- Q:A bearing assembly that can withstand greater torque (other requirements are not required and the axle is cantilevered)

- Torque? Bearings are not used to bear torque, mainly to bear axial or radial load

- Q:Can I use other types of bearings instead? What's the model instead of the bearing? Thank you

- Hello, please check the model of this bearing in detailThere is no PN307 modelWith RN307, cylindrical roller bearings, bore 35Then consult me

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

X-over sub for for conversion and connection of drill stem component in petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords