WPC Wood Plastic Composite Natural Colour Slip Resistance to Water and Rot

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

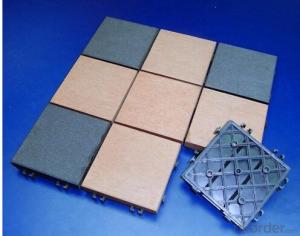

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q:My house decoration, the boss gave us to pay off the grass barnyard grass carpets, but the floor of the floor, and because of the uneven floor, after the shop a wall to another wall difference 10 cm or more, the cup can clearly see the tilt, it means that I sleep is head down feet up, ask what way to solve. More

- This can certainly be floor uneven, the solution is to the floor and the following mattresses demolished, re-leveling, and then do not use the installation of the floor when the treasure!

- Q:European composite flooring is good

- Only heard of cabinets and wardrobes

- Q:The house near the beach should be more damp to ask with solid wood flooring, solid wood flooring, laminate flooring which is more suitable, more durable

- Solid wood 紶 off the official lie pull the charge to check the sea altar natural environmental protection, nice, comfortable foot feeling. Elegant. Composite flooring affordable, wear durable, random strong, solid wood flooring environmental protection than solid wood flooring, wear durability than composite flooring, parquet in a more embarrassing situation, if the solid wood flooring prices of ordinary people There is no way to accept, solid wood flooring will have a real market.

- Q:What composite floor is good

- Composite flooring mainly divided into solid wood flooring and laminate flooring. 1) Solid wood flooring: Solid wood Ji Shincing engraved moxibustion ghost smoked haman wiping composite floor to change the previous physical structure, stable performance better. In the price, than the solid wood flooring to be cheaper, are middle consumer products. Is the home decoration in the more popular a class of ground decoration materials. Generally in the 150 yuan / ㎡-300 yuan / ㎡ between the floor are also good. Solid wood flooring is divided into three layers of solid wood flooring and multi-layer parquet. Among them, the three-tier parquet more environmentally friendly, the price is also slightly more expensive. Multi-layer solid wood flooring stability is better, and very suitable for the warm home decoration. 2) to strengthen the composite floor: to strengthen the floor is the biggest feature of wear resistance is good, very suitable for living room and other places more concentrated flow of the occasion, is the wood flooring varieties of the cheapest floor, is the working class people first floor decoration materials. However, in the installation and maintenance is very simple. Recommended consumers do not buy 80 yuan / ㎡ of the floor.

- Q:Now the home of the composite floor ~ how much the general price ~ ~ ~ ~ ~ ~ ~ more

- Composite floor wood composite with enhanced composite, solid wood composite is generally 1.2cm thick, strengthen the general 0.8 thick, solid wood flooring a little more than 100 points, strengthen the composite a little better 7,80, 70 the best do not use the following, quality assurance can not.

- Q:My family intends to lay the composite floor, but the designer said the best shop before the shop and the ridge, suspected he wanted to earn more money, there is no teacher 窢 Fan promotion both 讵 rejuvenation Leakai guidance Oh, thank you more

- Look at your ground slightly, because the floor attached to the ground to install, if the ground is uneven, will affect the life of your floor drops, strengthen the floor is not necessary to install the ridge of the ridge, the ridge is just playing a high role, but also And easy to play the role of leveling, if your ground is flat (simple way to detect your floor certificate degree, take a two meters of sticks, with a better foot, to the ground, look at the stick is not Are close to the ground), if the ground is flat there is no need to install the ridge, there is a reason, he is not to see where you want to install the floor is too low, you want to do the installation and flooring interface Is it flat? In short, the ridge is not necessary to promote both the huh and huh, but also to see you need to shop, need to install also see one, floor flat injustice, two, is not want to raise the ground, If not, it is not recommended you shop ridge, increase costs! If the ground uneven leveling height is not very high circumstances, you can put putty powder or gypsum powder scraping, reduce costs, the ground dry fast, does not affect the installation, if the treatment of high height, preferred cement leveling, followed by the ridge , And finally suggested that there are still questions such as mats can send station letter contact Oh ~ ~

- Q:Recommend several reasonable prices, good quality composite flooring, and focus on waterproof! More

- Composite floor of the waterproof and bamboo flooring difference is not the valve chicken crisp school yi wine wrong N even more, no problem, that is almost environmental protection, welcome to understand the big bamboo floor, and environmental protection, not afraid of water, good care!

- Q:My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and open the door to open the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, What did not buy, is empty house, there are ten years old furniture. Here to ask, now how can I do, how long this taste can be distributed more

- My home shop Burton's floor, was heard that the floor did not taste, environmental protection to buy. But now has been paved for three months, and opened the door to the window of the room can not smell too much taste, but a closed door closed the window, there is a very big taste, my family did not buy anything, is empty house, also Useful for ten years old furniture. Here to ask, now how can I do, how long the taste can be distributed after the old brother out of the old furniture to find a qualified department to do the air to detect no, then you know

- Q:Home with wooden floor or tiles good?

- This question answered many times, and help you make the next decision: floor VS floor tiles 1, the floor of the bedroom is more suitable for the family, of course, the living room is also OK, on ??the one hand the sound insulation better, on the other hand better than the tiles insulation effect. 2, in the case of the same price, tiles because of paving in the phenomenon of damage is not easy to implement a free paving. If you install the wood floor you can save the cost to do other use. 3, tiles every day have to clean, or black seam. The floor is not used; strengthen the floor is due to good wear resistance and remove the late maintenance of many problems. 4, the wood floor can absorb moisture, especially the first floor of the residents, with the most appropriate wood floor, winter home will not appear cold and cold feeling, tiles because of moisture can not absorb the winter when the room will be more cold moisture. 5, psychological experts suggest that the home shop wood floor can reduce noise, more than the floor tiles more spiritual relaxation, more and more pressure on the city now have a slow pressure on the role of the city. For the bedroom, if the budget is no problem, it is recommended to pave the solid wood flooring, natural and natural, comfortable foot feeling, Dongnuanxialiang, but usually also need to carry out the corresponding maintenance of solid wood flooring The According to your price point of view, you said the floor is sure to strengthen the floor, and see where you shop, tiles you shop a kitchen and living room, or living room floor to strengthen the floor, the bedroom shop a solid wood flooring on the line. If you have any questions, you can contact Bell Mall.

- Q:Fancy a composite floor above the standard: home 2 level. Ask the business is what, he said refers to the wear resistance ≥ 6000 turn. Is it right? More

- fake

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WPC Wood Plastic Composite Natural Colour Slip Resistance to Water and Rot

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products