Wpc Interlocking Decking Tiles from Chinese Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

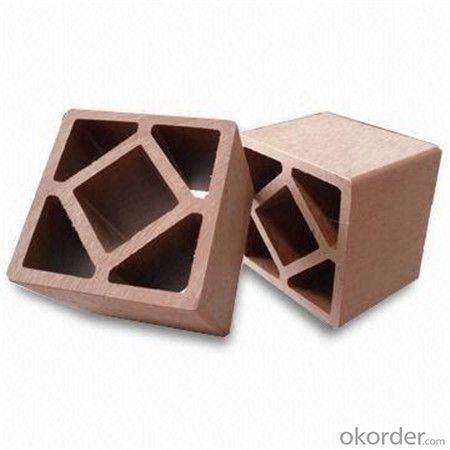

Structure of Wpc Interlocking Decking Tiles

| Company introduction: | As a professional manufacurer of composite wood plastic decking, we are specialized in producing& promoting environmental friendly composite wood plastic outdoor decking for years. Our sales network covers all over the world, and we've been proved as a trusted supplier to all our customers. For all the buyers who choose our products, you have our guarantee on both quality& service. |

| Material: | 60% bamboo/wood powder 30%HDPE |

| Features: | 1. Waterproof& fire resistant; 2. anti UV/ Fungus/ Insect/ Slip. 3. Tested mechnical performance 4. True-to-nature wood appearance 5. Recyled, easy installation& low maintance,long lasting life span. |

| Available finish: |

Brushed (Smooth), sanded or grained

|

| Colors Available: |

White,Black, Brown, Gray& Teak or customized

|

| Applications: | Home& Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground and so on. |

| Certificates: |

CE&ISO&SGS

|

| Size: | 150*25 mm |

| Finish: | grooved&sanded&grained |

Main Features of Wpc Interlocking Decking Tiles

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

Picture show of Wpc Interlocking Decking Tiles

Specification of Wpc Interlocking Decking Tiles

Name | Wpc Interlocking Decking Tiles |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

FAQ of Wpc Interlocking Decking Tiles

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q:What plastic floor

- Worry。 Its characteristics are stone, tiles and other incomparable.

- Q:What is a plastic floor?

- Due to its rich color, color variety and are widely used in home and commercial aspects, such as indoor homes and hospitals, office buildings, factories, schools, public places, supermarkets, commercial, stadiums and other places. The thermal conductivity of the PVC floor is good, the heat dissipation is uniform, and the thermal expansion coefficient is small, relatively stable.

- Q:The home is all ceramic tile or plastic floor

- Unwanted。 In winter, you can carpet in the bedroom. I hope my answer can help you

- Q:Wood floors and wood floors in the outdoor anticorrosion materials?

- Anticorrosive wood floor, is the common wood preservative treated as commodity processing, common wood floor in embalmed after the performance is greatly improved, reached the anti-corrosion, mildew, moth, anti termite effect. Nowadays, the antiseptic wood floor is one of the most widely used wood. For the open wooden floor outdoor environment, and can be used directly with environment water and soil contact, is the preferred material for outdoor wood flooring, flooring, outdoor landscape wooden platform, terrace floor, outdoor boardwalk and other outdoor wooden pergola.

- Q:Domestic anti - slip plastic floor leather with moisture-proof effect

- 1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factories, schools, hotels, hotels, KTV, bars, massage parlors, beauty salons (shops), clothing stores

- Q:What are the hazards of plastic floor

- Plastic floor leather, although difficult to burn, self extinguishing, but at high temperatures, will decompose harmful gases, excessive inhalation, suffocating

- Q:PVC plastic floor can be used as a kitchen operating room, right?

- 1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factory, school, hotel, hotel

- Q:Is the plastic paper between the wood floor and the closet

- It doesn't matter, it doesn't matter, because the floor is damp

- Q:Can the plastic stair step of the cement in the home spread the plastic floor

- Need to do cement self leveling. If the surface is flat, can be installed directly

- Q:What is the difference between plastic floor composite floor

- PVC floors and wood floors: wood floors can be broadly divided into three categories: solid wood flooring, solid wood flooring and laminate flooring. The wood floor is natural materials, synthetic materials have irreplaceable advantages, non-toxic and tasteless, comfortable, warm in winter and cool in summer

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wpc Interlocking Decking Tiles from Chinese Factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords