WPC Decking Wood Plastic Composite Anti-water, Anti-insect, Recycled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of WPC Decking :

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

Description Main Features of the WPC Decking:

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

indoor wpc flooring

deck wpc solid

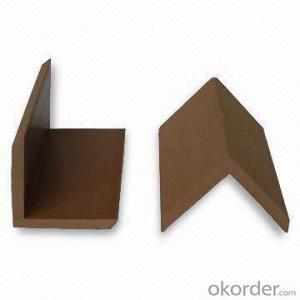

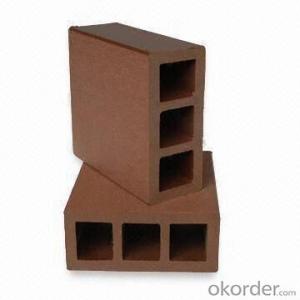

WPC Decking Images:

WPC Decking Specicication:

FAQ of WPC Decking :

1> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

2> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

3> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

4> How to buy and concerned terms?

*MOQ – 300m2 per item

*Lead time—2 weeks

*Departure port—Shanghai

*Package-- PE film, carton box or 2pcs.bundle, treated pallet

5> Certificates and Quality guarantee

*Certificates – CE&ISO 9001 complied

*Warranty—10 years

*Quality guarantee—test report for each order under the strict management system.

6> About CNBM and It’s WPC products

China National Building Material Corporation (CNBM), long history since 1984 is one of the top

fortune 500 corporation and central enterprise with total assets of more than $20 billion and

120,000 staff.

- Q:Is it necessary to glue the composite floor?

- In general, the quality of the floor have been better waterproof treatment, but can not guarantee the full waterproof; Second, the floor itself has the nature of wood, so the floor wet expansion and contraction, that is, when the wet will swell, dry Will shrink; for glue and do not glue, completely look at your own ideas, I tell you about, glue and do not glue the benefits and disadvantages. 1. glue: to prevent the entry of water, put an end to the deformation of the floor, but if there is a piece of floor damage, would like to change, then it is impossible, because the plastic, the floor has been formed as a whole, If you do not glue the floor, then the floor would like to replace any one of the floor, are relatively easy to replace, but the above said, To be good, the room can not be too wet, or easy to deformation. To sum up, if I use the floor at home, I may be plastic, because the glue after the floor is more stable, but that is very environmentally friendly glue, because the glue is water-soluble glue, there is no harmful substances, you Look at yourself. Have their own good, but also like not playing plastic. Hope to help you, hope to adopt!

- Q:How to choose a solid wood flooring

- How to choose a solid wood flooring

- Q:We are putting in maple floors and are considering engineered wood. Trying to research the engineered floors, I see alot of positives and not the negatives - yet there must be some! Any opinions?Also - would one be easier to install than the other?If it matters ... This is for the 1st floor our our house in South Eastern MA (about 6 miles from the ocean). Thanks

- The negatives are that the engineered wood floor can be refinished MAYBE once. Solid hardwoods can be refinished quite a few times before needing to be replaced. Most engineered floors can be installed as a floating floor, which is relatively easy for a DIY project. Hardwoods need to be nailed down. Engineered wood comes prefinished. Hardwood comes either way. The factory finish is the way to go. I have an engineered oak floor in my living room/dining room, and it's held up well to my daughter and 2 dogs. Hope this helps.

- Q:This question is also under remodeling.I'm considering installing Thomasville's Walnut engineered flooring, or solid Bamboo flooring from home depot throughout my upstairs. I would appreciate hearing from anyone that has installed either of these products.Specifically, do either of these floors dent and scratch easily? I have three cats, two children and my massage business in my home.Does one of these outshine the other? Does either hold up as well as any other product you might have experienced? Do you know of anyone who has used these? They are similar in price, so that is not a factor. Thanks and I look forward to input anyone can provide!Additional details: It looks like all the interlocking floors come pre-finished. All the others I'd have to stain and poly myself, correct? Since I don't build homes, I'm going for a balance between easy install and quality. Thanks!

- i know the solid abmboo would be the way to go for me...its a great product

- Q:If you want to shop on the original floor with laminated flooring what needs attention?

- 1, the original floor is a tile or composite floor, if the tile can be directly shop, but in the kitchen and bathroom joints to seal, to prevent moisture into. 2, if it is on the floor and then shop, to ensure that the original floor smooth, dry, because a number of the bottom floor deformation, the upper floor will be deformed. At the same time also consider the floor increased, the door should be shortened, the composite floor and the original tile floor of the convergence problem. (1) Solid wood floor flatness: If it is very narrow old wooden solid wood flooring, if there is uneven treatment. Such as loose, fixed firmly; if it is Alice, you can planing. Or simply remove one or two pieces, because the smaller area, does not affect the composite floor pavement. If it is wide board, to plan to deal with good. (2) check whether the sound of solid wood flooring, what causes, loose keel or loose floor. (3) keel integrity. Check the keel is loose, there is loose, to re-reinforcement; check whether there is rot, if the decay of aging, replace the new keel. Because the joint effect, if the keel is not good, will have a new composite floor impact. (4) all with more than a few years of solid wood flooring, in the floor before the composite floor, it is best to use the United States solid nail keel reinforcement.

- Q:Home decoration to shop composite floor, in the decoration of the city to see a very bright surface of the composite floor, the effect and the wax on the same as the solid wood flooring, and even bright. Called mirror floor. Do not know this floor can not buy, what exactly what the surface painted, so bright. How about the wear resistance, will not be a long time there is irreparable wear marks. Who is the home of the power ridge ding boge hi gong but the fence of this floor, please come to a proposal. Thank you More

- Wear resistance is not good, bright just used okay, with some of the time is not so bright, it is best to consider matt, because the time will not have much change, wear marks are not very clear, This is a good friend to tell me what you think about

- Q:How to take care of composite floor

- Upstairs to answer? Strengthen the composite floor basically do not need special care, because the strengthening of the composite floor of the surface is aluminum oxide, is a chemical composition, the general stains will not be invaded, only need not to use the drip on the OK The How to take care of the words, there is a building materials supermarkets to strengthen the floor of the oil can be considered, but it is nothing more than the top ten scrapped version of the calcium version of the water to shock the floor to polish a little more clear, no practical effect, so no need to spend this Money! Do not strengthen the composite floor must not wax, especially solid wax, if hit, the floor will become very flower and blurred, it is not easy to clean up! Counterproductive! I can be responsible for the above answer!

- Q:what is the primary differences between 5/16 and 3/8 engineered flooring - besides thickness?

- The thickness, the width and the length is about all there is to it /except the finish and or color

- Q:What is the general price of composite flooring?

- See the brand and the quality of the thickness. General no-name, about 60 yuan have. But the thickness is relatively thin. Mid-range needs 80-100 or so. If the brand of trace tube carved moxibustion to smoked pavement compound floor, in addition to special promotions, generally need 120 yuan a square. Good need more expensive

- Q:My house is a guest, and the middle is separated by curtains. The election of the bed, wardrobe, are white, above the embellishment of the frender of the spoons of the pity, Light color? Specific point is the best. Questions added: the top of the wall is white more

- Choose what color of the wooden floor depends mainly on the windows and doors and the color of the wall, the wall and the window and window cover is white, then very casual, and what kind of color wood flooring is not ugly, white with a good color. If the window and window sets of color is red, then the wood floor will try to choose the color of the deep point, so from the community feel more comfortable. There is an important factor is how your home floor, how to light. Good lighting on the random, the light is not good to try to choose a shallow warm color of the floor. After all, or to a little harmony and the top of the wall are white, furniture is white. So that the color composition of the home has been a lot of light, I recommend a dark color of the wood floor, so from the visual look is more comfortable. For example, a balloon if you do not catch it, then he will fly away. We are the same, the family of what are white, it should be a little deep choice of wood flooring, so that you can put the entire tone pressure. Another point to note is that your home on the floor, if the light is not good for the wind, then you can not use too heavy color, this point you own grasp it. Ha ha

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WPC Decking Wood Plastic Composite Anti-water, Anti-insect, Recycled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m

- Supply Capability:

- 20000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords