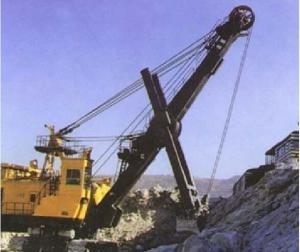

WP-6 Long Beam Excavator for mining on sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 3 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

WP-6 excavators are based on our WK-10B model; the changes introduced in its design mainly include elongation of its crane arm length, and a reduction of bucket volume from 10m3 into 6m3. They are suitable for railway transportation at opencast mines for deep extraction loading. Our WP-6 excavators meet international standards of quality.

Technical Spec. of WP-6 Excavator | |||

Normal bucket volume | 6m³ | Main motor | 750kW |

Length of boom | 22m | Max. Excavating radius | 24.25m |

Length of bucket stick | 13.2m | Max. Excavating height | 23.4m |

Traveling speed | 0.69km/h | Max. Dumping radius | 21.1m |

Max. Lifting force | 686kN | Max. Dumping Height | 17.7m |

Max. Pushing force | 392kN | Excavating depth | 3.6m |

Max. Crawling angle | 12° | Working weight | 498t |

Average bearing pressure | 255kPa | Theoretical productivity | 640m³ |

We have established a new production base in the Binhai New Area of Tianjin to facilitate the transportation and export of large-sized equipment. Our second wheel production line is currently under construction. We have also established production lines for wheels, axles and wheel sets for use at speeds above 200 km/h.

We are now turning our focus to international markets which we are certain can benefit from our high quality products and service. As we are constantly innovating and improving, we have no doubt that we will meet and even exceed our customers’ expectations.

- Q:I am doing a project in which I am facing a problem to calculate the fuel efficiency of the excavator (runs with diesel). could you please suggest any method or any instrument which will be helpful for me. (as I mentioned I got to measure in fuel consumption in certain period of time)thanks

- I used to drive tractors for a living, here is what i did. Fill up the fuel tank. Write down the hour meter of the excavator. Run the excavator. Fill the fuel tank from a service tank with a flowmeter on it. Check the hour meter again. Divide the fuel used by the time ran and bingo you have fuel used per hour.

- Q:engine

- TROLL ALERT - JOINED TODAY sry SENSor, I stole your job.

- Q:I am having a conversation over e-mail with a guy who says that Piltdown Man was being taught at the college level in the 1970's despite having been debunked 20 years earlier as a fraud. Is this true? Is there a good reason for it if it is? Can some one find me evidence of this?

- No. It was under suspicion for a long time, even before it was debunked in 1953. By the 70s it was old news.

- Q:A)regional political changesB)the better training excavators are receiving C)better pay for paleoanthropologistD)none of these

- A B and C

- Q:My family own a large landscaping and irrigation company and were thinking of buying a mini excavator for removing trees and planting bigger trees i.e. palms and such. We also install irrigation up to 4 inches of Pvc pipe and repair all kinds. Also French drains. If anyone has anything else I would love to know your opinions! All comments are welcome negative and positive. Thanks!

- If you're moving live trees of any substantial size, you need a hydraulic tree-spade, not an excavator, but you already knew that, since your family owns a large landscaping and irrigation company.

- Q:How large is the capacity of the 60 crawler excavator?

- Excavator bucket excavator digging machine is 60, according to the different brands with bucket capacity is different, like Komatsu PC60 bucket 0.28 and 0.37 two, with 60 of the 0.2 Party's Hitachi 60 is the 0.22 party, the Volvo 60 is the 0.22 party, the 0.2 party is Futian leiwo, Xugong 60 is the 0.23 party what to say is not the same, I was doing the excavator bucket, ripper to understand these, refer to it

- Q:HOW TO BECOME AN ENVIRONMENTAL CONTRACTOR EXCAVATION IN TEXAS?

- Well, to become an environmental excavation first you have to be land. Oh, I think you mean excavator. Then you'd need excavation experience and excavation equipment (backhoes and such). You'd probably need certification of some kind. For government jobs (the most common) you'd probably need to bid on a project, and they take the best bid. Texas government sites should have specific information on this. Knowledge of soil types, environmental habitats, erosion control, etc. would be useful.

- Q:How is the grade of excavator driver's license classification?

- Excavator driver's license is a special machinery operating permit, an operating permit on the line, but also on behalf of the certificateGo to the excavator school or go to the local labor bureau or the safety supervision bureau.

- Q:It's from manual for Volvo excavator: signal lamp for Igensatt Luftrenare; om lampan lyser medan motorn ar igangmaste luftrenareelementet bytas eller rengoras. ???

- I okorder /

- Q:I'll be 16 on April 12th. 2009... I don't have a license or permit for driving yet, because I haven't decided to read the booklet yet. I live in Hampton, VA and I wanna get a job for the summer in the Excavator/Dozer area, I have operated many tractors and such before, and know it can be very dangerous and know how to be safe, but is there anybody out there that will hire me?

- Good luck with that. You will be competing with people like me that have years of experience. You may want to find something in your area that does apprenticeship programs. Also, I'm kicking myself for not going into the union (Local 3) Spend a little time and money now, and make ship loads of money later.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WP-6 Long Beam Excavator for mining on sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 3 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords