Woven Polypropylene Geotextile with White Color

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Woven Geotextile Description:

Woven geotextile mainly uses polypropylene(PP),polyethylene(PE) as raw materials. After extruding.It has long term corrosion resistance in the soil and water with different PH;Due to its excellent microbiological degradation resistance. The material is light and soft, so it is convenient to transport and install.

PP Woven Geotextile Application :

Road Construction .

Embankment on soft soils .

Slope Reinforcement .

Reclamation and breakwater .

Earth/Rock dam and irrigation infrastructures .

Railway and airfield construction .

Sport and athletic field

Anti-weeds

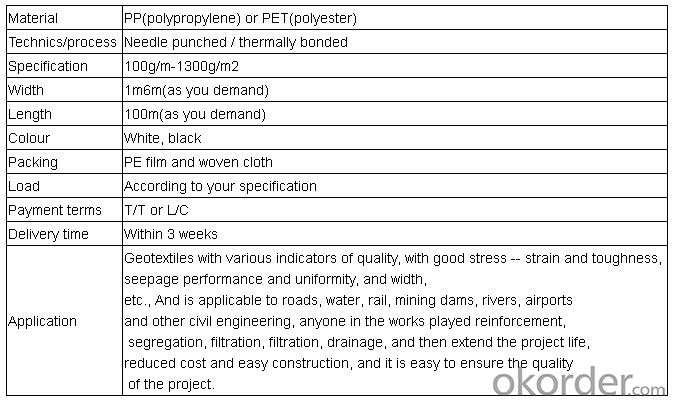

PP Woven Geotextile Specification :

Applications:

Water conservancy:

1.) sea wall, river bank, lake bank project

2.) River bottom protection, diversion and irrigate work

3.) Reservoir anti-leakage and delete danger and reinforcement

4.) Fence mud and land

5.) Soft body drainage

6.) geotextile sand flushing bag, land flushing bag

7.) emergency flood fighting

Road works:

1.) soft base reinforcement

2.) side slope protection

3.) Anti-reflective layer of pavement seam structure

4.) drainage system

5.) green belt for insulation

Railway works:

1.) railway foundation bed reinforcement,

2.) embankment slope reinforcement and protection 3.) Waterproof and drainage layer for tunnel inner wall 4.) geotextile drainage blind ditch

Air port works:

1.) runway base reinforcement 2.) parking apron and road surface structure 3.) airfield and drainage system

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:What are the advantages of using geotextiles in green roof design?

- Geotextiles offer several advantages in green roof design, including effective water drainage, erosion control, and protection of the roofing membrane. They also provide filtration and separation of soil layers, enhancing the overall stability and longevity of the green roof system. Additionally, geotextiles help in retaining moisture, promoting plant growth, and reducing maintenance requirements.

- Q:How do geotextiles help with soil reinforcement in geogrid applications?

- Geotextiles help with soil reinforcement in geogrid applications by providing additional support and stability to the soil. They act as a barrier between the soil and the geogrid, preventing soil particles from passing through the geogrid's openings. This helps to distribute the load more evenly across the geogrid, reducing the stress on the soil and preventing soil erosion. Additionally, geotextiles can improve the friction between the soil and the geogrid, enhancing the overall reinforcing effect and increasing the geogrid's load-bearing capacity.

- Q:How do geotextiles affect air quality?

- Geotextiles do not directly affect air quality. However, they can indirectly contribute to improved air quality by preventing soil erosion and reducing the release of dust particles into the air.

- Q:How are geotextiles affected by chemical exposure?

- Geotextiles can be negatively affected by chemical exposure, as certain chemicals can degrade the material and reduce its effectiveness. The specific impact will depend on the type and concentration of the chemical, as well as the composition and quality of the geotextile. Regular monitoring and selection of chemically resistant geotextiles can help mitigate the potential damage caused by chemical exposure.

- Q:How do geotextiles help in preventing soil erosion in vineyards?

- Geotextiles help prevent soil erosion in vineyards by acting as a protective layer. They are placed on the soil surface, acting as a barrier that prevents the topsoil from being washed away by rain or irrigation water. This helps maintain the integrity of the soil structure, retains moisture, and reduces the impact of wind erosion. Additionally, geotextiles promote better water infiltration and drainage, reducing the risk of runoff and soil erosion.

- Q:Is the filament geotextile the same as the tensile strength of other acupuncture nonwoven fabrics?

- Filament geotextile than acupuncture geotextile tensile strength 3 - 5 times

- Q:The outside of the blind tube is not to be with the geotextile 1 effect will be better?

- Plastic blind ditch is a new geosynthetics, is composed of plastic core wrapped outside the filter composition. At present the plastic core has several different cross-sectional shape rectangular, hollow rectangular, circular and hollow circular species structure of the plastic blind ditch products. Pass the water to see the original tie & gt; & gt;

- Q:Geotextile detection sampling, how many meters

- General a square meter can be, I professional production

- Q:What are the different types of geotextiles?

- There are several different types of geotextiles, including woven geotextiles, non-woven geotextiles, and knitted geotextiles. Each type has unique characteristics and is used for various applications in civil engineering and construction projects.

- Q:How do geotextiles help in groundwater protection?

- Geotextiles help in groundwater protection by acting as a barrier that prevents the infiltration of pollutants into the groundwater system. They are used in various applications such as drainage systems, landfills, and erosion control, where they provide filtration and separation of soil particles, ensuring that only clean water enters the groundwater.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

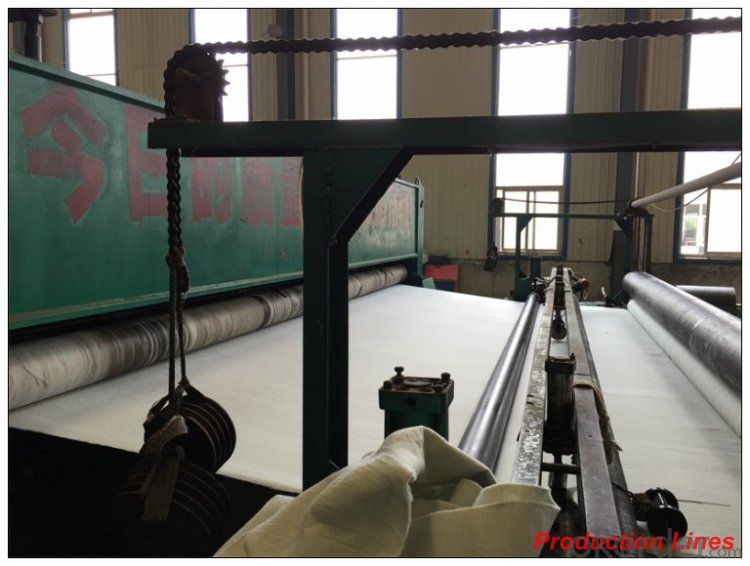

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Woven Polypropylene Geotextile with White Color

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords