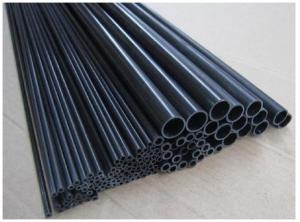

Woven 3K Square Carbon Fiber Tube Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction for Carbon Fiber Tube

♦These 3K Carbon Fiber Tubes Carbon are made of pure carbon fiber with beautiful twill weave

♦ Available in different colors and sizes.

♦ Customized specs are accepted.

2.Typical Features

♦ Low weight

♦ High strength

♦ High temperature resistance

♦ Abrasion resistant

♦ Good toughness

♦ Resistant to aging

♦ Anti static

♦ Conduction of heat,etc.

3. Technicial Process

Winding forming technology is a kind of products molding method to use presoak tape to roll on winding

machine with heat , he principle is making the fabric soften and making the resin of fabric molten by the hot roll

of winding machine,under a certain of tension, in the operation process of the roller, with the aid of friction

between the roller and the core mold to make the tape rolled continuonly on the core until reach the needed

thickness, then after cooling of the cold roll to finialize the disgn,take it off from the winding machinek,and put it

into the curing oven to curing, remove the core mold after curing and the products is finished .Winding pipe

has the advantage of high strength , high straightness ,and can make tapered tube the

4.Photos

- Q:Please let me know the features of fire blankets?

- I bake a lot! Especially during the holidays so I've used a variety of pans for every kind of cookie etc I've found that the cheapy aluminum ones work the best! To keep them from being ruined- I've been using SILPATS which can be found at BED BATH AND BEYOND, Linens and Things and even TARGET They are a bit expensive but, so worth it! It's silicone/fiberglass flexible mat that not only protects you cookie sheets but, is completely NON-STICK so cookies cook evenly and slide right off the sheet It also cools quickly for multiple batchesIt's also GREAT for rolling pie dough onto and cooking meats and other things They retail for around $20 a piece Just don't cut on them I have 5 that I use in my kitchen for the past 6 yrs I simply love them I get my baking pans for around $2-3 dollars a piece. Good luck

- Q:cant really figure it outcan you?

- no real way to stop them from stealing them but you're best chance would be to install a paging type alarm system so that it will notify you when the alarm goes off, install motion lights where you're car sits, get a dog any size will do as long as it will bark, go to harbourfreight web site and buy a security camera i think they still have them for $40.00, they are b/w with night vision and sound they hook to you're TVs A/V inputs, but the night vision is kinda weak after 20 feet, talk to you're neighbours see who stays up at night and who's home during the day and set up you're own neighbourhood watch, try to park you're car close to you're bedroom window, because they will use a cordless sawzall to cut out the converter, so welding wont help and trying to make a plate to cover it would only increase you're chances for a fire, most scrape yards pay between 10 and 40 dollars for converters depends on the type, the reason is for the honey combs inside of it, its some type of ceramic material, what its used for i have no ideal, but they want the guts out of them badly. I've heard roomers of the honey combs being used for some type of medical research, again its just a roomer. other than locking it up in a garage i guess you could air bag you're ride and set it on the frame when you're not driving lol would be alot harder to get to it that way . best of luck and i would get a good alarm and camera with sound, and try to park close to you're bedroom, if you do catch them in the act i wouldn't confront them keep you're distance, call the cops which will take a hour for them to show I'm sure and yell what do you think you're doing to my car or something like *^*%^*^*%^ away from my *(^%(^% car you ^*%$*^%lol, from a safe distance,

- Q:PVC pipe joint leakage how to do?

- Solution of water leakage in sewer pipe:1, if the water is PVC, will be able to buy a PVC pipe to pick, put the tube cut broken, the first set of interface end into the pipe, the other end of the cut position coincides with a hole in the interface of Qi Ping, making it just to straighten. Then send directly to this end, the two ends have a certain cross then distance (length) and then put it down, with lateral water pipes and the two in the PVC at both ends of the inner side direct glue.2, you can buy waterproof tape to repair the water pipe, it is entangled with the line, and then mortar, waterproof agent and cement on it.3, can not handle, it is better to find a professional company.

- Q:I'm still in the process of getting used to an electric stove. I'm planning on frying meatballs in canola oil and I'm wondering what heat setting I should use. I need it to be hot enough to actually cook the ground beef but not too hot because our smoke detectors are super sensitive. Thanks!

- Whose owns the smoke detectors? Where are you? If you OWN the residence, you are probably not even required to HAVE smoke detectors. In that case, you can do anything you want tot them. If you rent an apartment, or the detectors are not in your residence, you could be guilty of destruction of property ans potential liable for any injuries resulting from the detectors not working.

- Q:The difference between expanding, clamping sleeve and welding pipe joint

- Flaredfitting: flaredfitting medium: oil, water, gas and other non corrosive or corrosive medium pipe joint with steel pipe specifications and flexible pipe welding, has the characteristics of reliable connection, good sealing performance, so it is widely used in oil refining, chemical industry, light industry, textile, metallurgy, national defense, aviation, shipbuilding and other systems; also suitable for hydraulic transmission of various mechanical engineering, machine tools and other equipment pipeline.

- Q:Okay, so I recently found out that I'm moving back to the US from south east Asia. My BFFaeaeaeae lives there and it's terrible being away from her! We see each other ever Christmas and Summer and practicality live at each other's houses when I'm home. She always asks when I'm moving back but since i never dreamed that it would happen before college, I've always told her that it's not going to happen.But,Now it is going to happen and I need a FUN way to surprise her with the information! I thought about writing her a letter and then sending it so that when she opens it she's surprised. I'm sure there's an even crazier way to break the news! So, i need ideas!Thanks!!!D

- A DOZEN QUESTIONS?? Do you want us to do your homework? Read it yourself, ask your teacher if you have questions. Pay attention in class instead of thinking about a party, TV show or whatever! That's how you LEARN! You won't learn ANYTHING if someone else does your homework!

- Q:I need to know an example of a problem astronauts faced in space preferably 2 examples but one will do. For example, to product the international space station requires a large amount of money. The solution was that by pooling together money, countries are able to achieve more than they could by themselves.

- Sharkbite connectors are the easiest connectors, you just push on. Good luck

- Q:I know about the tent and sleeping bags. But for fire and food and going to the bathroom etc

- yes it is cause it keeps your hands safe i am a nursing assiant and i have to gloves all the time

- Q:Even though his face looked more messed up GSP was clearly outstriking Shields for at least 3 or 4 of the 5 rounds and was never in danger of losing. After 4 rounds of futility why didn't Shields or his corner try a different gameplan? Would have made for a much more entertaining fight.

- Pump performance drops off sharply with increases in the Total Dynamic Head. TDH is the sum of the static head (height of discharge) and the dynamic head (resistance of pipe and fittings). Only small pumps are measured in GPH instead of GPM. 125 GPM (7500 GPH) is not a small pump. Their instructions call for a 18 dia. basin 30 deep. I would not go less than 24x36 for a basin on that size pump. If the basin is too small, the pump will short cycle, and even with internal temperature protection, it could burn out in a few days of short cycling. Be sure to put some holes into the bottom of the basin even if you are filling it from a drainage pipe from the side, as water pressure from the ground will float the basin up out of the hole. The weight of the pump is not enough to hold it down, in most cases. Be sure to drill a 3/16 hole in the pipe between the pump and check valve, preferably just above the pump discharge outlet, to prevent an airlock from damaging the shaft seal. It also needs a dedicated 15 amp circuit, with nothing else plugged into it. Personally, I would go with a Zoeller model 292, for that application, but the price would be much higher for a pump of Zoeller quality. They also have excellent technical support.

- Q:Why is the water purifier of the PE pipe and quick connector contact after the start of Water Leakage, can be pulled out after turning and then inserted into the PE pipe does not leak, what is the reason ah, who knows?

- The main technology of water purifier is derived from two kinds of ultrafiltration membrane and RO reverse osmosis membrane. It is a small water treatment equipment for water purification. The water purifier is usually used as a small filter for household use.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Woven 3K Square Carbon Fiber Tube Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 watt

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords