World-Beating Solar Cells-25 Years Life Time-17.6% Effiency

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction of Solar Cells

A solar cell, is an electrical device that converts the energy of light directly into electricity by the photovoltaic effect, which is a physical and chemical phenomenon. It is a form of photoelectric cell, defined as a device whose electrical characteristics, such as current, voltage, or resistance, vary when exposed to light. Solar cells are the building blocks of photovoltaic modules, otherwise known as solar panels.

Introduction of our Company

Our core business is the design and manufacture of III-V epitaxial material used in cellular phones and other wireless devices, and the design and manufacture of solar cells and solar sheets for a variety of applications, including unmanned aerial vehicles (UAVs), spacecraft, and terrestrial collectors.

Founded in 2000, we are well equipped to conduct its business. The company occupies a 30,000 square foot facility in Niles, a northern suburb of Chicago, Illinois. The facility contains a clean room and device fabrication and test laboratory. We own all the tools and equipment necessary to grow, fabricate, and test epitaxial material and solar cells and sheets. The company owns a set of metalorganic chemical vapor deposition (MOCVD) tools capable of high volume production. We also possess the tools and equipment required to fabricate and test semiconductor device structures and solar cells.

We are dedicated to producing quality products to meet customer needs. We are an ISO 9001-certified company. Production begins only after we are sure that all required customer specifications have been met. In order to ensure the quality of our products, we employ sophisticated quality control processes.

We prides itself on the quality of its employees. Some members of our technical staff are among the world’s foremost experts in the growth and processing of GaAs- and InP-based electronic devices and solar cells. Our staff supports customers, not only during the product development period, but also during production in order to enable continuing improvements in final product performance and yield.

We also performs contract research and development. Since 2003, we have been a prime federal contractor on more than thirty programs to develop solar cells, transistors, and lasers. A key result of this innovation has been the development of the epitaxial lift-off (ELO) process, which uses in its line of solar cell and solar sheet products. We have also supported other companies in the performance of their research and development programs. Many of the innovations developed at our have been incorporated into commercial products.

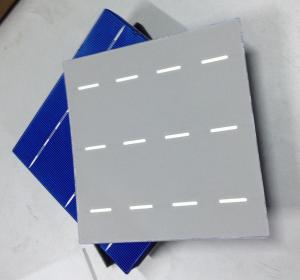

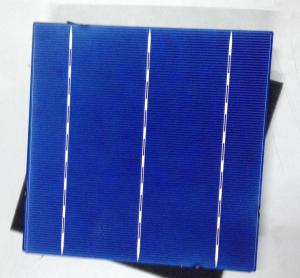

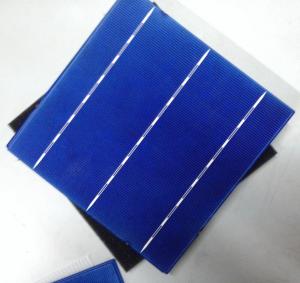

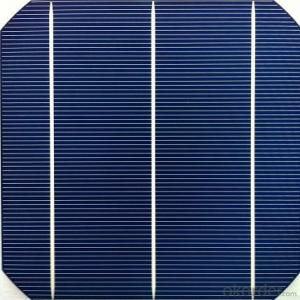

Specifications of Polycrystalline Solar Cells

Format : 156 mm × 156 mm ± 0.5 mm

Thickness: 210 μm ±40 μm

Front (-) : 1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride)

Back (+) : 2.5mm wide soldering pads (silver) back surface field (aluminium)

Efficiency (%) | Pmpp (W) | Umpp (V) | Impp (A) | Voc (V) | Isc (A) |

18.00% | 4.38 | 0.528 | 8.291 | 0.631 | 8.869 |

17.80% | 4.33 | 0.525 | 8.252 | 0.629 | 8.821 |

17.60% | 4.29 | 0.532 | 8.053 | 0.633 | 8.541 |

17.40% | 4.23 | 0.528 | 8.092 | 0.624 | 8.632 |

17.20% | 4.19 | 0.524 | 7.992 | 0.62 | 8.458 |

17.00% | 4.14 | 0.52 | 7.972 | 0.623 | 8.5 |

Advantage of Polycrystalline Solar Cells

1. Tire-1 Solar Cells’ Manufacturer Quality Guarantee. With a complete and sophisticated quality government system, our Quality Management have arrived world’s leading place. Customer can receive Tire-1 Cells Maker’s Quality Standard Products.

2. Trusted Warranty. We can supply trusted after-sales service to our customer. If our cells are found not in conformity to the specification of manufacturer, or should the inspected quantity found in shortage, or should the packing found damaged, the buyer has the right to claim to the seller. The claim, if any, should be presented to seller within 30 days after cargo's arrival date to the port, together with related inspection report and photos issued and provided by a reputable independent surveyor such as SGS.

3. World’s Leading Manufacturer Equipment. We imported the newest and leading production equipment from abroad. Advanced equipment can guarantee the stable quality of cells. Auto production line can also save labor cost which will further cut our production cost.

4. Bulk supply: With the production capacity of 500MW, we can produce large quantity every month. This can satisfy most customer requirement.

Usage of Polycrystalline Solar Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; our solar cells have passed IEC Certification. With high and stable quality, our cells can greatly improve the performance of Solar Modules.

Applications of Polycrystalline Solar Cells

Assemblies of photovoltaic cells are used to make solar modules which generate electrical power from sunlight, as distinguished from a "solar module" or "solar panel". A solar array generates solar power using solar energy.

Packaging & Delivery of Polycrystalline Solar Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid of water, sunshine and moist.

Factory Picture of Solar Cells

Package Picture of Solar Cells

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. What’s price per watt?

A: It’s depends on the quantity, delivery date and payment terms of the order. We can talk further about the detail price issue. Our products is high quality with lower price level.

2. Can you tell me the parameter of your solar cells?

We have different series of cells with different power output, both from c-si to a-si. Please take our specification sheet for your reference.

3. How do you pack your products?

We have rich experience on how to pack the panels to make sure the safety on shipment when it arrives at the destination.

4. Can you do OEM for us?

Yes, we can.

5. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The perfect time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:Can solar cells be used for telecommunications infrastructure?

- Yes, solar cells can indeed be used for telecommunications infrastructure. Solar cells can generate electricity from sunlight, which can be used to power various telecommunications equipment such as cell towers, base stations, and repeaters. This renewable energy source helps reduce dependence on traditional power sources, increases energy efficiency, and can even enable telecommunication services in remote or off-grid areas where grid power is unavailable.

- Q:How about the solar cell 156mm Mono-Crystalline?

- If you are getting this kind of solar cells-Mono Solar Cell measure by 156mm, the light intensity is 1000W/㎡, 25 ℃, AM1.5

- Q:How many solar cells are there in a solar panel?

- 20?

- Q:What is the difference between a solar cell and a solar panel?

- A solar cell is a single unit that converts sunlight directly into electricity, while a solar panel consists of multiple solar cells connected together to generate a higher amount of electricity.

- Q:Solar water heater plate can be directly converted into electrical energy?

- batteries: generally lead-acid batteries, small micro-system, can also be used nickel-metal hydride batteries, nickel-cadmium batteries or lithium batteries. The role is to light when the solar panels issued by the energy stored to the need Time to release again.

- Q:Can solar cells be used in farming or agriculture?

- Yes, solar cells can be used in farming or agriculture. They can be employed to power various agricultural equipment, such as water pumps, lighting systems, and irrigation systems. Additionally, solar cells can be installed on the roofs of farm buildings or on open fields to generate electricity, which can be used to power farm operations or sold back to the grid. This allows farmers to reduce their reliance on traditional energy sources, lower their operating costs, and contribute to a more sustainable agricultural industry.

- Q:How do solar cells perform in high pollution areas?

- Solar cells perform less efficiently in high pollution areas due to the reduced amount of sunlight reaching the cells. The presence of pollutants in the air, such as dust, smog, and particulate matter, can block or scatter sunlight, decreasing the overall solar irradiance available for conversion into electricity. This lowers the energy output and effectiveness of solar cells in such areas.

- Q:What is the impact of hurricane-force winds on solar cell efficiency?

- The impact of hurricane-force winds on solar cell efficiency can be significant. These strong winds can cause physical damage to solar panels, such as breaking or dislodging them from their mounts. This not only affects the overall functionality of the solar system but can also lead to a decrease in energy generation. Additionally, high winds can result in the accumulation of dust, dirt, or debris on the surface of the solar panels, reducing their ability to absorb sunlight and convert it into electricity. Therefore, it is crucial to ensure proper installation and maintenance of solar systems in hurricane-prone areas to minimize the negative impact on efficiency.

- Q:How do solar cells convert sunlight into electricity?

- Solar cells convert sunlight into electricity through a process called the photovoltaic effect. The cells are made of semiconductor materials, usually silicon, that absorb photons from the sunlight. These absorbed photons excite the electrons in the material, allowing them to break free from their atomic bonds. The freed electrons then flow through the cell's material, creating an electric current. This current can be harnessed and used as electricity to power various devices and systems.

- Q:How are solar cells different from solar panels?

- Solar cells are the individual units that convert sunlight directly into electricity, while solar panels are a collection of these cells that work together to generate a larger amount of power.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

World-Beating Solar Cells-25 Years Life Time-17.6% Effiency

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords