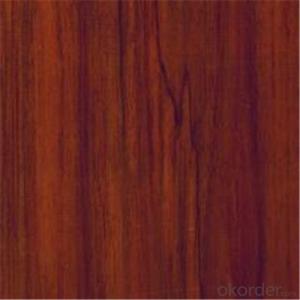

Wooden Pattern Printed Prepainted PPGL Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description of PPGI:

1. Width: 600~1250mm

2. Thickness: 0.19~1.50mm

3. Grade: JIS G3312-CGCC, CGC340-570, (G550) ASTM A755M CS-B, SS255-SS550

4. Coil Weight: 3~10Mt

5. Coil ID: 508mm/610mm

6. Chemical Treatment: Chromated (Cr 3+, 6+, 0+)

Festures of PPGI:

Building industry | Outdoor application | Roof, structural balcony, panels, window sills, window frames, gates, garage doors, rolling doors, booths, shutters, watch rooms, makeshift houses, street waiting room (booth), refrigerators, etc. |

Indoor application | Room doors, dividing walls, door frames, light house steel structures, sliding doors, screens, ceilings, toilets, interior elevator lobby, stairwayventilating duct, communication pipelines. |

Specifications of PPGI:

(1). Thickness: ≥20μm

(2). Pencil Hardness: 2H

(3). 60° specular glossiness of coating: >60

(4). 180°bend: ≤3T

(5). Impact: ≥9J

(6). Salt Fog Resistant: ≥500h

(7). Color difference: <0.8ΔE

Images of PPGI:

FAQ:

1.What about the delivery.

We can arrange the shipment about 15-25 days after the deposit.

2.What about payment term?

30% T/T deposit, balance against B/L copy.

Full T/T payment if quantity less than MOQ.

3.How much about MOQ?

Normally 100pcs,but small order is acceptable as well.

- Q:What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil can vary depending on its intended use and manufacturing specifications. However, common dimensions for a steel coil typically range from 0.15 to 3.5 millimeters in thickness, and 600 to 2,000 millimeters in width. The inner diameter of the coil can be around 508 to 610 millimeters, and the maximum outer diameter can be up to 2,000 millimeters.

- Q:How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being cut and formed into various components, such as brackets and supports. These components are then assembled and welded together to create the frame and structure of the shelving unit. The steel coils provide strength and durability to the shelving units, ensuring they can withstand heavy loads and provide long-lasting storage solutions.

- Q:ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- Look for buffing compound at the hardware store. Home depot lowe's od even Wal-mart/ There is a compound for steel and for iron. I t will not make iron real shinny but it will make it look good. This stuff is to be used with a buffing wheel but I have used it on rags and it work great.

- Q:How are steel coils inspected for defects after rewinding?

- Steel coils are inspected for defects after rewinding through a combination of visual inspection, non-destructive testing (such as ultrasonic testing), and dimensional measurements. These inspections help identify any surface imperfections, internal flaws, or deviations in size, ensuring that the steel coils meet the required quality standards.

- Q:Some stainless steel products are as shiny as chrome. Can all/most stainless steel be polished to a chrome like luster.

- The nickel and chromium content do have some effect on shine. But mostly they effect the corrosive and rust resistance property's of the stainless steel. 300 series stainless steel such as 304e or 316e will not rust like 400 series 416e eventually will. All types of stainless steel can achieve a bright shine. The key is using jewelers rouge and the correct buffing wheel. Avoid scotchbrite if you want shine. It will clean your stainless steel but it will not shine it the way you want. Miketyson26 (certified tig welder)

- Q:How are steel coils used in the agricultural industry?

- Steel coils are commonly used in the agricultural industry for various purposes, such as manufacturing equipment like plows, harrows, and cultivators. They are also used for constructing storage structures like grain bins, as well as fencing and livestock enclosures. Additionally, steel coils are used in the construction of agricultural machinery and vehicles, ensuring durability and strength in demanding farming conditions.

- Q:How are steel coils used in the manufacturing of hydraulic cylinders?

- Steel coils are used in the manufacturing of hydraulic cylinders as the raw material for creating the cylinder body. The steel is typically rolled into a coil form and then cut into specific lengths and shapes to construct the cylinder barrel. This allows for precise and durable construction of hydraulic cylinders, ensuring they can withstand high pressure and heavy loads.

- Q:How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are rolled and shaped into various structural components like beams, girders, and plates. These coils provide the necessary strength, durability, and flexibility required to support heavy loads and withstand the dynamic forces exerted on the bridge.

- Q:What are the different types of steel coil surface treatment methods?

- There are several different types of steel coil surface treatment methods that are commonly used in various industries. These methods are employed to enhance the appearance, durability, and performance of steel coils. Some of the common types of steel coil surface treatment methods include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc. The zinc coating provides excellent corrosion resistance and protects the steel from rusting. 2. Electro-galvanizing: In this method, a thin layer of zinc is electroplated onto the surface of the steel coil. It offers similar corrosion protection as hot-dip galvanizing but with a thinner coating. 3. Cold-rolled steel coil: This process involves passing the steel coil through a series of rollers at room temperature. It results in a smooth and polished surface finish, which is ideal for applications that require a high-quality appearance. 4. Pre-painted steel coil: Also known as color-coated steel coil, this treatment method involves applying a layer of paint or coating onto the steel surface. It provides an attractive appearance and additional protection against corrosion. 5. Phosphating: This treatment method involves applying a phosphate coating onto the steel surface. Phosphating improves the adhesion of subsequent coatings, such as paint or powder coating, and provides corrosion resistance. 6. Chromate conversion coating: This method involves applying a conversion coating, typically using chromium compounds, onto the steel coil surface. It enhances the paint adhesion and provides corrosion resistance. 7. Passivation: Passivation is a chemical treatment that is used to remove iron oxide and other contaminants from the steel surface. It improves the corrosion resistance of the steel coil. 8. Oiling: Oiling is a common surface treatment method that involves applying a thin layer of oil onto the steel coil surface. It helps to prevent corrosion during storage and transportation. These are some of the commonly used steel coil surface treatment methods. The choice of treatment method depends on the specific requirements of the application, such as corrosion resistance, appearance, and performance.

- Q:full discription about hydrolics used in steel melting shop with hyd valve is use in thair circit too ?

- The correct spelling is hydraulics. I haven't heard the term steel melting shop you probably means a foundry or a steel mill The most obvious example i can think of is hydraulic-operated fork lifts. Hydraulic cylinders are used to lift the forks and to tilt them upwards or downwards. The valves are coneccted to levers next to the steering wheel. Hydraulic pressure is supplied by a hydraulic pump driven by a propane or diesel engine. In some forklift designs the wheels are also not connected directly to the engine, but driven by hydraulic motors. There are also a large variety of machines used in steel mills and metalworking companies to cut and shape metal parts. for example, press brakes, plate cutting shears, stamping presses, hole punch machines, drawing presses, etc. These types all operate in much the same basic way. They use a very large cylinder or group of cylinders to apply many tons of force to different kinds of metal working tools.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wooden Pattern Printed Prepainted PPGL Steel Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 m.t.

- Supply Capability:

- 1200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords