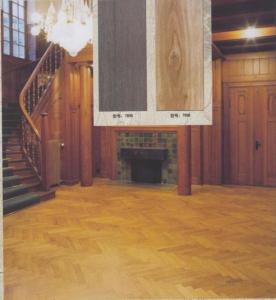

Wood texture wpc decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood-Plastic Composite (WPC) floor accessory is manufactured from a combination of plastic, natural fiber and some additives using special equipments. It mixes natural fiber and plastic perfectly to keep the natural impression of wood but with rich colors of plastic. It has gradually replaced wood and plastic, getting widely used in more and more fields.

For our wpc decking floor, there are many kinds of types, such as TW-K01(150 x 35 mm)TS-01(150 x 25mm), TH-07(140 x 30 mm), TS-A01(90 x 20mm),TH-16(133 x 24 mm, solid design) etc..

1. Material: 50% natural wood flour; 35%~40%HDPE, 10%~15% additives

2. Color: cedar, grey ,red pine, coffee, brown, nature wood etc.

3. Usage: outdoor, garden, summer house, villa, pool surrounds, exterior floor, seaside walk board etc.

4. Normal length: 5.4 meters/pc, can also be cut according to the requirement of customer.

5. Surface treating methods: Brushing, groove, sanding, embossing etc.

6. CE Approved

7. Advantages:

Keep the excellent character of plastic | Have the properties of wood | Produce fire-new WPC |

weatherproof | easy to cut, fix and glue | Can be recycled with 100% |

no crack, split, warp, or splinter | easy to tenon , drill and nail | No sting of wood |

High dimensional stability | Natural feeling0 | Requires less routine maintenance |

Resistance to insects | Resistance to UV | Is environmentally friendly |

easy to manufacture manifold profiles | innocuous | Multicolor, and needn't to painting |

- Q:Sun Yanzi singing the song lyrics I have a big house, there is a large landing windows, the sun spread on the floor, but also warm my quilt song is what ah

- Is the day of the "perfect day" album in the same name title song "perfect day" lyrics: I want a big house has a large floor window sunshine sprinkled on the floor also warm my quilt I want a big The house has a lot of rooms a room with the fastest web a room a lot of guitar a room with my nice clothes a room a friend and his lover a room a room I do not know what to put about us Do not sleep at night daytime thinking in the bed puppy running in the house to spend the perfect day through the perfect day

- Q:Hi I would like to clean my room's floor with dettol. But I don't know how to use it. It is a bottle and there's dettol liquid inside there. I'm thinking to mix with water and then use cloth to clean the floor. How many dettol drops should use for 1 litre of water?

- if you have a wooden floor that's been varnished use only cold water to clean it. If you have a shiny tyle or type type floor like kitchen or bathroom you can use windex on it and it will shine super nice. Otherwise if the floor is not plastic but is the old type tile then use joy liquid detergent on your kitchen floor then use Johnson & Johnson liquid wax on it.

- Q:My bro bought a house and some of the floors are not even. (He got no basement.) What can he do to make the floors straight without investing too much money?

- A good tile installer can use self leveling or pull mud if its radical.

- Q:how do you take up linoleum on a wood floor with out damaging the wood

- Not damaging the wood just can't be avoided, but you can minimize the damage by working slowly and carefully. Start by removing the linoleum with a pry bar such as a wonderbar. If the adhesive is strong, then you will have to tap the end of the wonderbar with a rubber mallet to scrape up the lino. Be sure to wear a respirator since that old glue may contain asbestos fibers. Once the lino is removed, you can go after the adhesive. Keep in mind that any adhesive remover you put on the floor will seep into the wood, and prevent future adhesives from sticking. It can also interfere with how you stain the wood. Boiling water seems to be the method of choice to loosen the glue. It's applied in small amounts, and then the softened goo can be scraped it off with a putty knife. After the bulk off the goo is off, your floor can be lightly sanded. editted to add that while a heat gun can also work, it's not recommended if you plan on staining the floor. If you are not experienced with heat guns, you can scorch the floor and discolor it permanently.

- Q:I am looking at putting down flooring thoughout my home.I am curious to know which is the best the laminated flooring or the snap together flooring.I have carpet down now in most of the rooms with the exception of the bathrooms kithchen and utilitie rooms.

- My center sister spoke of as on the instant, and informed me that my older brother has Alzheimer's and is going to be institutionalized. Charlie and that i been estranged on the grounds that adolescence, something we renewed approximately ten years in the past. something in my lizard suggestions needs to be happy that he's suffering, and concurrently i think responsible for having that impulse. the only sturdy memory I even have of Charlie is as quickly as we've been youngsters and for Christmas we bought one yet another plastic cannons which shot wood shells. We used them to shoot the glass balls off the Christmas tree. My father had a manner of announcing Merry Christmas that made it sound like he had in basic terms cursed you. It felt like Dad had come domicile returned.

- Q:How to quickly remove the glue on the floor

- There are special in addition to glue spray, you go to the building materials supermarket to find (do not get hard, damage the surface)

- Q:Flooring paved, but the place where the wall is seated, how to solve the dust

- If you do not want trouble can only wipe every day. If you are not afraid of trouble, then need to be removed and re-installed. Open the floor and then use a vacuum cleaner to suck out the ash. After cleaning up the dust and then do the installation. Flooring, wall joints can be used glass glue 1. along the gap coated with glass glue. 2. glass glue is dry, with your fingers along the gap evenly. 3. Fingers wipe, with a wet towel to the surrounding excess glass glue can be.

- Q:I slip when i do roundhouse, front, jump kicks on WET FLOOR.Solutions to this??

- it sounds like you need more fleibility in youre legs and hips. when you kick as high as you can youre muscles stretch like a rubber band wanting to snap back. with more flebility you can handle more tension. as keep youre balance as youre first priority. like my coach always said when youre off balance thats when bad things happen

- Q:Is the color of the angle to be the same as the door or the floor? How to choose the color will look beautiful? More

- According to my years of experience in contact, home improvement of the base line color, the basic and the floor color is similar. Consistent with the floor is basically impossible, because the household open sauce satin and other pimple advised to slip for their not to support. Do not contrast too much, otherwise you will regret it.

- Q:I'm in the upstairs area of a building and when I lift weights the floors squeak horrindously. I'm only here for a few weeks and I'd like to know if there's a mat or something that I can put on the floor.

- the reason why the floor squeaks is because the subfloor has come loose from the joists. You can add more screws to the the flooring in the loose spots, that usually does the trick. Tool Belt Diva

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood texture wpc decking

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords