Wood Plastic Outdoor Decking in Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Engineered Flooring | Place of Origin: | Beijing, China (Mainland) | Brand Name: | CMAX |

| Model Number: | CMAX S140H25A, CMAX S140S25C | Technics: | Wood-Plastic Composite Flooring, Wood-plastic composite flooring | Name: | Wood Plastic Composite |

| Dimension: | 140X25CM | Length: | 2.2m,2.9m,5.8m,or customized | Color: | light grey, dark grey,chocolate,ipe,teak, yellow, black,other |

| Surface: | Sanded,Brushed,Embossed,Original skin,Grooved | Composition: | 60% wood/bamboo powder,30% HDPE,10%chemical addItives | warranty: | 10years |

Packaging & Delivery

| Packaging Details: | Unit Wrap, Carton and Pallet |

| Delivery Detail: | 15 days upon confirmed order |

UV resistant Waterproof Co-Extrution Wood Plastic Composite, WPC with CE

Advantages

1. Recyclable, Eco-friendly, saving forest resources

2. With the look of the natural wood, but less timber problems

3. Moisture/water resistant, less rotten, proven under salt water condition

4. Barefoot friendly, anti-slip, less cracking, less warping

5. Requires no painting, no glue, low maintenance effort

6. Weather resistant, suitable from minus - 40 to 60 centigrade degree

7. Termites and insects resistant, and moldy-proof

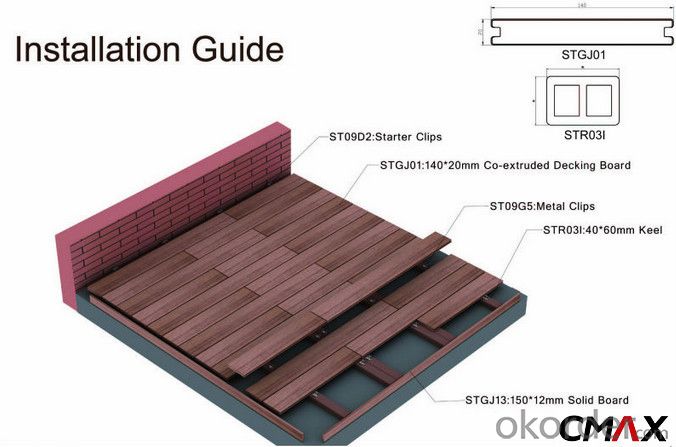

8. Easy to install and clean

Specifications

Component | 30% HDPE(Grade A recycled HDPE) 60% bamboo/wood fiber component 10% chemical addItives New material capped outside |

Design | Solid decking/Hollow decking |

Length | 2.2m,2.9m,5.8m or customized |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors ( IPE,Walnut,graystone,Cedar,Rosewood) or customized |

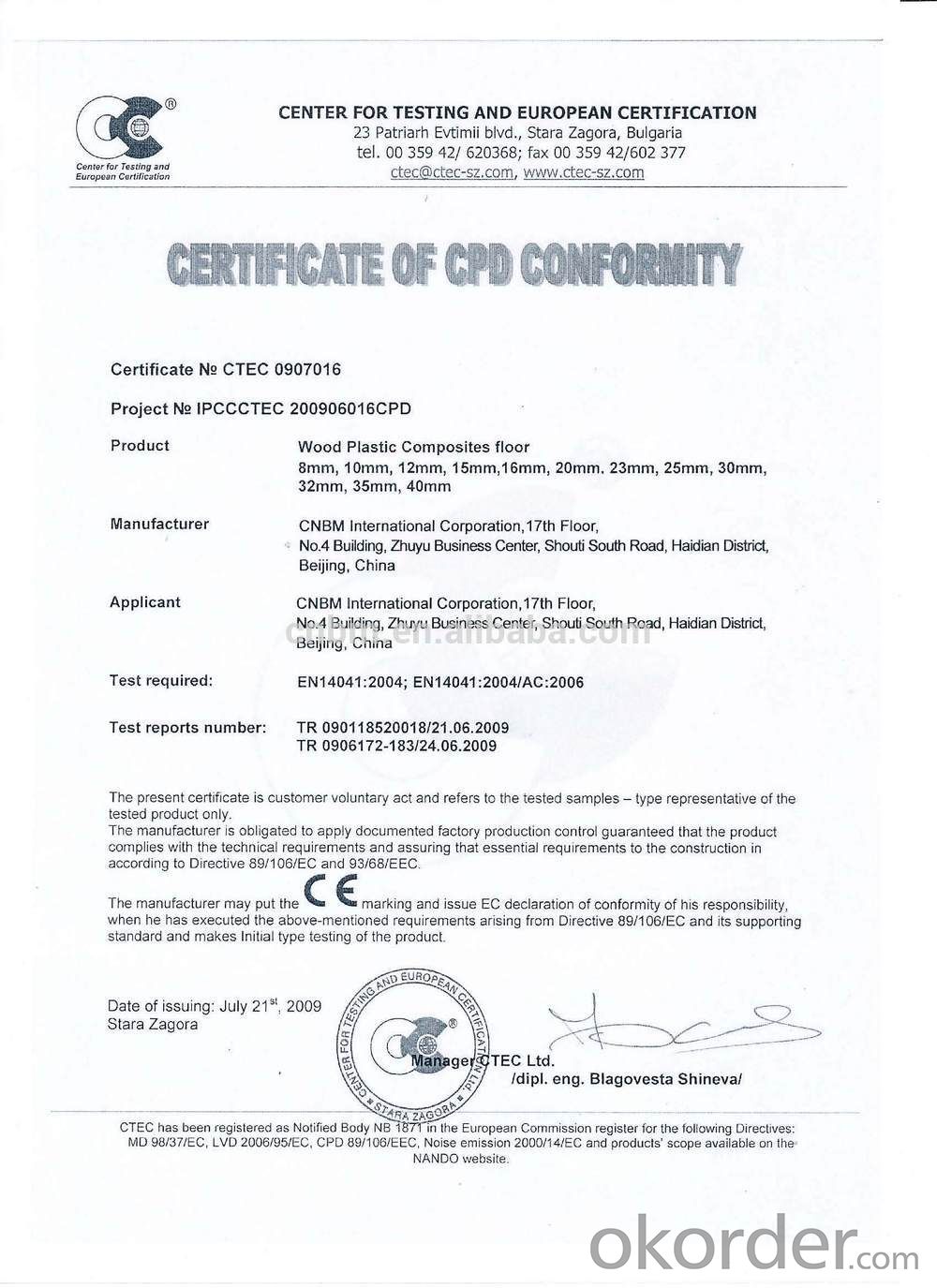

Cerfiticate | ISO9001, ISO14001, CE, FSC Certificate, etc. |

productive process

Certifications

Installation

Company Information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

Since 2004, the trading volume of CNBM International has been doubled in 5 successive years owing to the support of superior corporations and effort of all staff. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target.

In line with the business, CNBM International launched E-business platform Okorder.com.

Our goal is to transform CNBM International into the global leading brand in building materials industry within 3 to 5 years through innovation and reform, by strengthening the overall management of supply chain, developing and cultivating both domestic and overseas market, improving the procedure and information system, enhancing the ability to organize resources and to provide value-added services under a professional team and a learning organization.

With the advantages in Cement, Composite Materials, New Building Materials and Engineering, we mainly concentrate on coal, steel and construction equipments and give priority to solar and wind energy development simultaneously utilizing our competitive position on traditional building materials to achieve sales revenue of RMB10 Billion in 2013.

CNBM International is highly recognized by its business partners and clients all over the world and has obtained rapid development under the spirit of win-win. We will carry on the mutual beneficial, innovative and revolutionary trading structure as we did before, create value for our employees, share holders and clients and benefit the whole society in our future development.

- Q:Parents because of the order of the decoration of the house and noisy, my mother foolishly write the first letter of the first floor, brush the wall, the father said first shop wood flooring, I think the wood flooring easy to paint, so would like to ask, specific Order in general. (My house 137 square feet) more

- Oh, my mother is right. Generally in the pipeline and the installation of the line, the interior decoration sequence, should be uphold the truth from top to bottom. Can be so explained, the operation of the paint is the most dirty, if the first to do the ground, the finished product insist on the closure of the Mongolian Feng Feng phthalate care is critical, or is likely to cause secondary rework. Home ceiling is relatively simple, but the process of chip, or will cause pollution to the wall. So, avoid reversing their interrelationships. (This opportunity, you can give my father a lesson, (* ^ __ ^ *))

- Q:Please say it? The The

- Solid wood flooring is all the whole body of solid wood, usually processed for the whole piece of wood, but also through the finger-shaped long and horizontal fight width. Solid wood composite flooring is generally divided into three layers of solid wood composite and multi-layer solid wood composite, which three layers of solid wood panels, buffer cork core board, balance the bottom plate Layer composition, in the foot feel the closest to the solid wood flooring and a very good solution to the deformation, the European application of OKorder children's high-twisted chestnut thighs for the Lou more; multi-layer solid wood composite is laminated on the substrate substrate solid wood From the solid wood flooring is not easy to deformation, more applications in North America; if it is geothermal, it is recommended to choose a dedicated multi-layer parquet.

- Q:What is the difference between multi-layer solid wood flooring and solid wood flooring and laminate flooring?

- This question is a bit complicated, simply say it solid wood flooring is the main material of wood to do the wood, so the natural texture, foot feeling good. Many solid wood is the surface of a wood is also a base composition of Dan grass grass Ji Yu wasteland factory. Strengthen the floor is mainly the substrate, the surface paper (both imported paper, imitation wood texture, there are other different colors) on the top attached to wear into. Wear-resistant in more than 6000 rpm as good anti-UV wear is not easy to wet, do not fade, good care.

- Q:Does anyone have any experience with painting a wood floor white? How did it come out and how long did it last? Did it get dirty very fast?

- I have painted some floors in my time. They can hold up if done properly. Any floor gets dirty depending on any number of factors. If you choose to try it here is the answer I provided to a similar question . Sanding first is the best way to start. Make sure you vacuum with the brush attachment on your vacuum cleaner and then wipe with a tack cloth or a clean white cotton rag dampened with paint thinner or mineral spirits. If you cannot deal with the dust wiping with a deglosser will work (check your local hardware/paint store). As suggested an oil base primer is the next best step (although there are some quality latex primers on the market). A topcoat of either an oil base or latex floor and porch paint is recommended (they come in colors including white). The oil base will take the wear better. The latex finish will eventually wear down leaving an eggshell like finish. Some people prefer this look. If you use latex you can put a polyurethane clear coat over it to add durability. However, it will also make the floor slicker, much like wax. Be careful how you clean your floor. Paint normally takes thirty days to cure and should not be cleaned the first week. After one week a mild soap and water cleaning is alright. Solvent and abrasive cleaners should never be used.

- Q:What is the width of each piece of composite wood flooring?

- Composite flooring is generally 125MM, large board is 165MM

- Q:1) Show that, for any real number x, the expression "ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] always equals either floor(x) or ceiling(x). In what circumstances does each case arise?I think it equals floor(x) when x is negative and ceiling(x) when x is positive, but I can't do the general proof.Background information: Floor of a real number x = the largest integer less than or equal to xCeiling of an real number x = the smallest integer greater than or equal to x-floor(x) = ceiling(-x)if x is an integer then floor(x)=ceiling(x)

- If x=2k, k∈?, ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = ceiling[2k + 1/ 2] - ceiling[k + 1/4] + floor[k + 1/4] = = (2k+1) - (k+1) + k = 2k = x = floor(x) = ceiling(x). ---------- If x=2k+1, k∈?, ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = ceiling[2k + 1] - ceiling[k + 1/2] + floor[k + 1/2] = = (2k+1) - (k+1) + k = 2k = x = floor(x) = ceiling(x). ---------- If 2k < x ≤ 2k+1/2, k∈?, = 2k+1/2 < (2x+1)/2 = x+1/2 ≤ 2k+1 = ceiling[(2x+1)/2] = 2k+1 and k+1/4 < (2x+1)/4 = x/2+1/4 ≤ k+1/2 = ceiling[(2x+1)/4] = k+1 floor[(2x+1)/4] = k Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+1) - (k+1) + k = 2k = floor(x). ---------- If 2k+1/2 < x < 2k+1, k∈?, = 2k+1 < (2x+1)/2 = x+1/2 < 2k+3/2 = ceiling[(2x+1)/2] = 2k+2 and k+1/2 < (2x+1)/4 = x/2+1/4 < k+3/4 = ceiling[(2x+1)/4] = k+1 floor[(2x+1)/4] = k Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+2) - (k+1) + k = 2k+1 = ceiling(x). ---------- If 2k+1 < x ≤ 2k+3/2, k∈?, = 2k+3/2 < (2x+1)/2 = x+1/2 ≤ 2k+2 = ceiling[(2x+1)/2] = 2k+2 and k+3/2 < (2x+1)/4 = x/2+1/4 ≤ k+1 = ceiling[(2x+1)/4] = k+1 floor[(2x+1)/4] = k Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+2) - (k+1) + k = 2k+1 = floor(x). ---------- If 2k+3/2 < x < 2k+2, k∈?, = 2k+2 < (2x+1)/2 = x+1/2 < 2k+5/2 = ceiling[(2x+1)/2] = 2k+3 and k+1 < (2x+1)/4 = x/2+1/4 < k+5/4 = ceiling[(2x+1)/4] = k+2 floor[(2x+1)/4] = k+1 Then ceiling[(2x + 1) / 2)] - ceiling[(2x + 1) / 4] + floor[(2x + 1) / 4] = = (2k+3) - (k+2) + (k+1) = 2k+2 = floor(x).

- Q:Ok so my stupid friend which i really like and are best friends was trying cocaine and some dropped on the dirty floor and there was like cigarette ash and everything and it was a granite tile floor type and he chose to sniff it off of there can he get diseases like aids/hiv from there? im scared for him but hes just crazy and stupid,

- If this is for real, then absolutely yes, you have a disease.It's called Obsessive Comulsive Disorder, or OCD. There is a genetic component, but it is treatable--usually with anti-anxiety meds, sometimes with the newer antidepressants,in combination with therapy/councelling--particularly coginitive behavioural therapy.I think some good results *can* be had with therapy alone , too. I don't know where you are, but a good GP will immediately recognise what you are talking about. Also a TONNE of info on the net. Go--go now, and channel some of that drive into finding some help for it. That is not any way to live! Bless, and good luck:)

- Q:My dog urinated on our laminate wood floors and how the floor seems to have lifted, almost like air bubbles along the seams of the flooring. It looks horrible and I feel like these floors should be resistant to water and other liquids. Can anyone help?

- This Site Might Help You. RE: Can you fix warped laminate flooring? My dog urinated on our laminate wood floors and how the floor seems to have lifted, almost like air bubbles along the seams of the flooring. It looks horrible and I feel like these floors should be re...

- Q:I have laminate flooring through out my apt. including my bathroom. Well, my toilet overflowed and I need to disinfect the floor. I do not own a steam mop. Is there a cleaner I can use that will disinfect and not harm the floor?

- Get some laminate floor cleaner at a home improvement store. It usually contains alcohol. I like to apply it with a Rubbermaid Reveal mop. They sell them at Walmart and other places. You put your own cleaner in the reservoir and it has a pump handle to spray it on the floor (like a swiffer wet jet). Instead of disposable pads, it uses a washable microfiber pad.

- Q:Is dance flooring that plastic floor stuff, linoleum??Is it the same thing, or something else?Because I want to buy some cheap floor that is suitable for dancing on, maybe even the same as the ones they have in dance studios.Do you know:a) What dance floor is?b) Can you buy it cheap?c) Is there any flooring similar?d) Where can you buy them from?Thank you xx

- My girlfriend and I do ballroom dancing. The best floorings we have danced on are clean and recently waxed wood flooring and marble. Most dance studios I visited before signing up for lessons for us had parquet wood floors for their dance floors. Likewise for most halls that were rented for weddings we've attended. The marble floor of one hall was really nice to dance on as well, but the cost may be prohibitive since marble isn't cheap. The thing about clean and waxed wood floors is that it allows the women's feet to pivot for turns-- it is neither too slippery nor too sticky. Parquet floors, in my humble opinion, are not pretty. However they are only slightly more expensive than a good linoleum floor where I am at and you can make the dance floor any size you like easily since they are a floating floor. I have never had the opportunity to dance on linoleum, but if I think back I remember them being more sticky than I would prefer. If the floor is too sticky then it can put too much torsion on the girls ankle which is the case when you have a dirty unwaxed wood floor as well. I think the linoleum in all the kitchens I've ever been in were to 'soft' and gave too much traction. We did dance on the cheap, hard vinyl composition you see in schools, hospitals, and department stores once. It was okay-- good even. I can see that commercial stuff being usable-- and it is ultracheap.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Outdoor Decking in Best Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords