Wood Plastic Decking with high quanlity in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of Wood Plastic Decking Description

Item | WPC Project Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Wood Plastic Decking

WPC/PVC outdoor decking, indoor decking, soft pvc decking, wall panel, handrail, arbor,stand colum, tray panel, keel, grilling, connection, horny line, great wall panel, buckle ceiling, square pillar, door frame, door line, door mullion, PS foam profile, Accessoreis

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

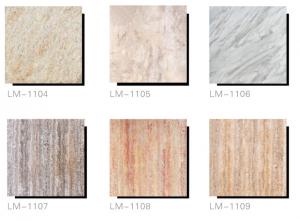

三.Wood Plastic Decking Images

四.Wood Plastic Decking Specification

Name | Wood Plastic Decking |

Size | W*H=145*30 mm |

Length | 2200mm, 2900mm, 5400mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Wood Plastic Decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q:2mm thick PVC plastic floor is generally one square meter

- PVC is soft and hard, transparent and opaque, different products, different formulations, and after the amount of plasticizer and filler no number, density difference, common hard transparent PVC is 1.34 g / cubic centimeters, opaque hard PVC to 1.7 also, transparent soft PVC to a minimum of 1.22 so, do not know the opaque.On compromise 1.5g/ cubic centimeters =1500KG/ cubic meters.2mm thick PVC square meter volume is 0.002 square meters. So 2MM PVC sheet weighs about 3KG.

- Q:Plastic floor prices, plastic floor how much a square meter?

- Plastic floor because of its variety of colors, color is widely used in various fields such as home decoration. Since the plastic floor into the Chinese market, has attracted great attention, as a kind of new material on the floor, with the compressive strength, abrasion resistance, environmental protection and sound absorption characteristics, and the plastic floor decorative effect is very good, so the development possibilities of the floor is gradually recognized by consumers.

- Q:To warm the original heat, the plastic floor above the surface of the floor to warm the heat emitted by the heat of the gas smell harmful to the human body?

- Floor leather containing lead compounds, in the use of the process, with the floor leather wear, lead content continues to spread, lead dust in the air, easily accessible to infants and young children

- Q:Domestic anti - slip plastic floor leather with moisture-proof effect

- 1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factories, schools, hotels, hotels, KTV, bars, massage parlors, beauty salons (shops), clothing stores

- Q:Plastic foam flooring is not a large mosaic floor.

- You can put in a layer of foam on the floor quilt or blanket. This is safer. Foam floor dirty or a block of cleaning, more convenient.

- Q:Worried about a long time, plastic aging, small ironExpose the floor.

- Very good, maple furniture, material is also good! The design is a combination of Chinese and western, so like a modern American, Jane, pastoral, Mediterranean, Chinese, Southeast Asian style decoration can not pick collocation, decoration! Do the old American color is also very beautiful, not easily outdated! And its furniture is also very focused on the functional and user-friendly, very practical.

- Q:What are the reasons for the price rise of PVC plastic floor

- Defects are thermally stable and shock resistant are poor, both hard and soft PVC easy to produce brittle during use. General PVC is not containing the relevant national standards allow the use of two (2 - ethylhexyl) adipate plasticizer (DEHA), DEHA in the high temperature (over 100 degrees Celsius) easily released, after contact with human health hazard.

- Q:The advantages of plastic floor tile

- Plastic floor than the floor brick advantages are: green, super thin, super wear-resistant, high elasticity and strong impact resistance, strong anti slip 6, 7, 8 fire retardant waterproof, sound-absorbing noise, antibacterial properties, acid and alkali corrosion resistance, easy maintenance etc..

- Q:Board PVC plastic floor plastic toxic

- PVC floor "refers to the use of polyvinyl chloride material production floor. Specifically to the polyvinyl chloride and its copolymerization resin as the main raw material, filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet substrate, the coating process or by rolling or extrusion process and.

- Q:PVC plastic floor glue thickness can be used for welding

- Coil and sheet, so there are two kinds of glue:

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Decking with high quanlity in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords