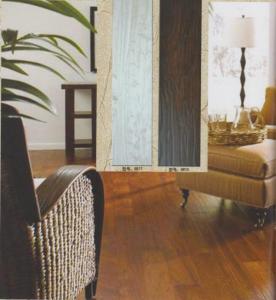

wood plastic composite wpc decking floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

WPC Decking Details:

| Minimum Order Quantity: | 1000 Meters | Unit: | m | Loading Port: | China Main Port |

| Supply Ability: | 20000 Kilograms per Day 24Hours | Payment Terms: | TT or LC | | |

Product Description:

Introduction of WPC Decking

1. Green ecological, Innovative technology, Lifestyle

2. Elegant nature wood grain texture and touch, with wood scent

3. Elegant and detailed shape design

4. Resistant to cracking and splitting

5. Water-proof, moldy-proof, prevents rotting and moisture, anti-acid, alkali and pest resistance

6. Environmental friendly, fully recyclable and no other hazard chemical

7. Safe to use for many years

8. No painting, no glue, free maintenance

9. Anti-slip, less crack and warp, barefoot friendly

10. Good weatherability, suitable from -40°C to +60°C

11.Easy to process install and clean

12.UV resistance, Fade resistant Durable

13.Dimension stability against moisture and temperature

14. High quality with competitive price.

- Q:Please refer to the ceiling for the floor, or the floor, how does its ownership confirm?

- I think the house actually buy the space ... ... that is, the interior of the building should be free of their own ....... I also feel a little pull but it seems like this ..... As if you can split your room alone? You do not have this flower open lamb satin bar and so cut the right to slush, but the room is your Arab, this thing, that is such a meaning, the concept of space I think The most suitable for the floor should be the top, because the first floor and the top floor of the situation

- Q:what should you use on a cement floor that has been painted with paint. spray paint gloss finish or floor wax. ?

- you can get wax for concrete floors...Lowes, Home Depot...just ask them...you need a polisher (one of those rotary ones.)

- Q:Our common room tile floor has kind of a dirty/worn look to it (might be grout?), and it's not really being taken care of by mopping. we're looking for an industrial-type way to clean it. what is the difference between floor stripping and polishing (and the machines involved)? and what would be better for our purposes?THANKS!

- The process of stripping a floor is to remove all the build up wax that accumulates in time . Polishing is to shine the wax that you apply to it , you can polish with a floor polisher every day if you wish to take scuff marks off and dust at the same time . I have always used paste wax when I polished my floors and stripped them down with Varsol You can purchase a floor polisher that serves dual purpouse ,it comes with felt pads for polishing and scrubby pads for stripping. You can also rent a machine for this type of job Home Depot rents them out.

- Q:I want to know how tall a building is by knowing how many floors are in it.I know this may vary from building to building, so specifically, how tall were the floors in the World Trade centers (twin towers)?

- Not only do floor height (which is measured from top of floor to top of floor) vary by building, they also vary from floor to floor, based upon slab thickness, the purpose of the floor, and the location of the floor within the overall tower in terms of which story it is. Per Wiki, the height to the last floor was 1355ft, with 110 floors, which averages out to be 12.32 (or 12 feet, 4 inches) per floor, which sounds about right to me.

- Q:Are unlevel floors always a sign of some sort of structural damage( framing, floor joysts etc) ? Or are there other causes? If so, what are they?

- usually it is caused by shifting foundations or support columns. Alot of times the foundations were never strong enough to hold the weight especially the center support columns. the exterior walls hold up and the heavy wieght of the house sinks the undersized support column that probably has no footing into the ground.

- Q:I am getting ready to lay some laminate flooring. I am going to replace the bueatiful parquet flooring the previous owners left in the dining room and the linoleum tiles placed over the linoleum sheet floor in the attached kitchen!! (The previous sentence was written with sarcasm!!) I have removed the parquet and both layers of linoleum, and was left with the subfloor covered in dry glue where the parquet was and what looks like floor leveler where the linoleum was. The glue for the parquet is some what even but coarse, the "floor leveler" is cracked and big pieces are missing sporadically around floor where it came up with the flooring.I was wondering how even the floor has to be for the laminate? I am going to be putting down padding, but want to make sure I don't have boards that sink when you walk on them. If you do recomend me removing the filler and the glue, what do you think I should use?Thanks.

- The click and lock laminate flooring can go over a floor or subfloor with irregularities. I locks together as a sheet, and is a floating floor. You must be certain to use the underlayment, or it will squeak like crazy, and make certain that ALL the joins are true, with NO gapping or you will have huge problems down the road. If you have two pieces that absolutely won't join smoothly, even with tapping, put them aside and place them with a different sheet. No amount of hitting and yelling will make them work together.

- Q:I'm building a house on Sims 2. Once i completed the walls for level 1 of the house, i moved up to the second level to build there but for some reason the floor tile grid is not complete. I can't build the walls as the floor has gaps in it. Does anyone know why this is? and how can i prevent it?

- It's both that you just should not have a wall at the first ground, you'll be able to placed a kind of columns within the construct mode to position help on your second ground. Or it is that you just constructed a staircase there. Hope I helped! :)

- Q:My family to buy a light yellow wooden floor of the house is a white door is also a white floor to eat hungry thirsty 丨 Chicken check the blood of the foot of the skirting is a white look good? The seller is recommended close to the floor of the color than the floor deep I am more inclined to white is not know good or not

- And the same as the floor and the door can be the same ah.

- Q:Composite floor a package is the number of square meters

- Under normal circumstances, 810 ^ 130 ^ 12 specifications of the floor is 20 a pack, a package is 2.106 square meters 1215 ^ 165 ^ 12 specifications of the 10 a pack, a package is 2. square meters 1215 ^ 195 ^ 12 specifications hides Compiled drink makeup table Taibo 10 a pack, a package is 2. square meters

- Q:How thick must the floor be over the joists? Does the thickness include the floor covering (tile)?

- I'm not a contractor or am I familiar with anything regarding New York but I am familiar with floor installation. I do know however that floor covering be it tile carpet or whatever does not include the thickness of the floor. I would also imagine that most building codes for floor thickness, would be at least 1/2 inch plywood over the floor joist. Also with ceramic tile,it is not recommended that it is installed on only one layer of plywood over the joist.You need 2 sheets or installed over the existing wood plus a cement board

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

wood plastic composite wpc decking floor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products