Wood Plastic Composite Outdoor Exterior Deck for Landscape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood Plastic Composite Decking- Hollow Decking

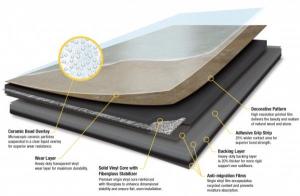

1.Description of Composit Decking

1.Item:RMD-53

2.Sizes: 140*25mm, 150*25mm, 225*30mm, 135*27mm, 120*25mm, 160*25mm, 100*25mm, 295*24mm,also we can make us customer request.

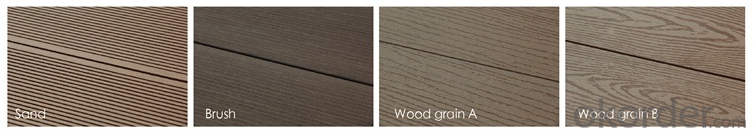

2.Surface Treatment of Composit Decking: smooth, sanded, brushed, wood grain

3. Component of Composit Decking

50% wood fibers + 40% HDPE + 10% chemical additives

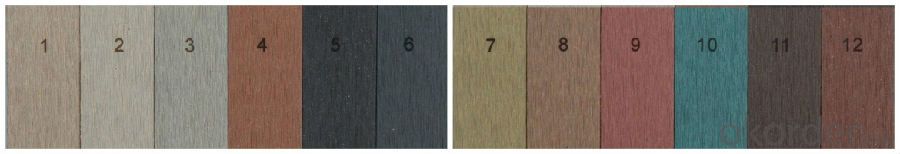

4.Color of Composit Decking

Black, coffee, brown, gray, redwood and more

5.Production of Composit Decking

6.Application of Composit Decking

Courtyard, Villa garden ,Private yard,Roof ,Balcony ,Dock,Swinning pool

Garden,Lawn,Balcony,Corridor,Garage, Pool and Spa Surrounds,Boardwalk,Playground

7.Features of Composit Decking

·Looks and feels natural wood

·Eco-friendly, high-recyclable, green material

·No cracking, warping and splitting

·Water/moisture-proof, corrosion-resistant

·Low maintenance and no painting

·Easy to install, clean

·Weather-resistant, suitable from -40 ℃to 60℃

·High degree of UV and color stability

Certificate by CE ,SGS,ISO, INTERTEK

Warranty 5 years!

Free Samples are Available!!

- Q:There is a layer of plastic on the floor of the room

- The ground cushion treasure is a new type of lightweight sheet made of polystyrene resin and other additives. The utility model has a continuous uniform and dense surface layer and a closed cell structure, and the wall of the honeycomb structure has the same thickness. Therefore, the utility model has the advantages of superior thermal insulation performance, good moisture resistance, long durability, high compression resistance and good sound insulation effect. And it is non-toxic environmentally friendly products.

- Q:Is it suitable for plastic floor? What's the harm?Is it suitable for plastic floor? What's the harm? Please specify. With price

- Since the plastic floor can go to the public life, it shows that it has its own unique advantages:1 elastic, comfortable, can give people a warm feeling;2 surface into the UV treatment, pollution resistance, easy to clean;

- Q:Free glue self-adhesive stone PVC floor leather plastic floor glue floor toxic

- Basic non-toxic, some domestic manufacturers can not guarantee the return material

- Q:What is the difference between plastic floor and floor leather? What is the wear resistance of plastic floor? How to distinguish the quality of plastic flooring?

- Floor leatherThese two kinds of materials due to the very simple and inexpensive, had a few years ago, the rage. But because of tile retrofit and composite wood flooring, floor leather is so beautiful as before. Now choose more for rent and borrow a house, but it does not mean that the floor has come to an end: a new type of floor leather has been published, it is similar to the marble and granite pattern, color is more diverse, texture is better than the traditional floor leather, but it is more than and 100 yuan the price per square meter is not so ", so the family decoration amiable and easy of approach" is not very much in.

- Q:With this plastic floor mat bed can not? Will not have any impact on people

- Good insulation, but not breathable, it is best not to use directly on the bed! It's better to use a sponge mattress!

- Q:What a pig with plastic floor to sell, how much money

- Advantages of polypropylene K8303:Good mechanical properties, high heat resistance, long life 5-8 years, chemical stability.The surface smooth high strength, good toughness, corrosion resistant parts of piglets in farrowing crate deformation, bearing capacityThe utility model has the advantages of strong force, long service life, no fear of flame, and the use of a flame sterilizer.

- Q:The family is decorated with the plastic corrugated pipe buried in the floor tiles under the good?

- Well, the principle of the circuit is to change the wall and the top surface. Do not go to the ground, there is danger to go after the wire is to go down, only the water pipes have to go to the ceiling and ground debate

- Q:What are the hazards of plastic floor

- The utility model relates to a plastic floor leather, which belongs to the soft floor, which is made of polyvinyl chloride resin as the main raw material, and is added with appropriate auxiliary agent.

- Q:PVC plastic floor glue thickness can be used for welding

- Coil glue and sheet glue, glue abbreviation: PVC floor, sports floor, plastic floor,

- Q:Wood floor plastic liner on the above or below

- We can, but generally we have put the word above.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Composite Outdoor Exterior Deck for Landscape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords