Wood Plastic Composite Decking / WPC Board / wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of Wood Plastic Composite Decking / WPC Board / wpc decking Description

Item | WPC Project Decking-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of Wood Plastic Composite Decking / WPC Board / wpc decking

Wood Plastic Composite Decking / WPC Board / wpc decking

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

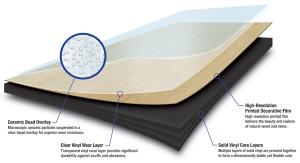

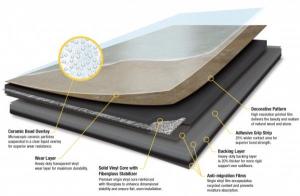

三.Wood Plastic Composite Decking / WPC Board / wpc decking Images

四.Wood Plastic Composite Decking / WPC Board / wpc decking Specification

Name | Wood Plastic Composite Decking / WPC Board / wpc decking |

Size | W*H=145*30 mm, CUSTOMIZED |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of Wood Plastic Composite Decking / WPC Board / wpc decking

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q:How long can be used for plastic floor restaurant

- Commercial flooring / plastic flooring1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factory, school, hotel, hotel4, life: 6 years to more than 15 years5, thickness: 2 mm6, color: more than 207, size: 20 meters long, width of 1.8 meters, 2 meters8, suppliers: Shanghai, Shanghai and the United States floor9, price: different thickness, different grades, different PVC content, different prices.10: Shanghai, the United States and the United States commercial floor price of 2 mm to 50 yuan per square meter installation price11, place: gray, wood12, family selection: red, blue, black, wood13, kindergarten; pink, green, yellow

- Q:Heard that there is a special plastic floor nursery? What are the benefits

- Decorative strong: floor design is a very important part of the kindergarten environmental design. Children from the first step into the park, the first to attract their attention is the color, followed by the image, the last is the text. Children are in an important period of physical and mental development and rapid development. Therefore, the kindergarten plastic floor according to the children's imagination and association of color and psychological feelings, through the floor color and pattern design, to give children a healthy, happy, positive space environment

- Q:Is it suitable for plastic floor? What's the harm?Is it suitable for plastic floor? What's the harm? Please specify. With price

- Since the plastic floor can go to the public life, it shows that it has its own unique advantages:1 elastic, comfortable, can give people a warm feeling;2 surface into the UV treatment, pollution resistance, easy to clean;

- Q:Plastic floor how to taste?

- We can Naganbu wet, dry for 2 minutes, mainly to prevent Bree water penetrated into the surface, and then take the wet cloth to clean the floor.

- Q:Today, just to shop on the EVA pad, the smell is very heavy to check it? What harm to the body

- Do not ignore the air circulation, ventilation for at least 4 hours a day, so that it can effectively eliminate harmful gases, is an effective way to prevent bacterial reproduction and increase oxygen. Floor should try not to composite floors, pure wood floors and wood floors best

- Q:Construction process of soft plastic floor

- 2.1 material:2.1.1 cement: suitable for Portland cement, ordinary portland cement, the strength of the grade should be above 32.5; different varieties, different grades of cement is strictly prohibited mixed.2.1.2 sand: medium sand or coarse sand should be selected, the mud content shall not be greater than 3%.

- Q:Plastic floor can be used indoors

- Compared with wood plastic floor: 1, fireproof performance, flame spread, anti burning cigarette burns; 2, surface hardness, scratch resistant properties than wood; 3, not easy to deformation, good dimensional stability; 4, pattern design, decorative effect, pattern selection is better than the floor; 5, with better performance, can heat welding processing, so that the seam is achieved completely waterproof, dustproof, waterproof, anti bacteria, mildew, moth effect; 6, the noise is small, can be reduced by 6-14 dB, more conducive to noise control when walking; 7, wide application range, not only suitable for Home Furnishing is also suitable for the local flow in many public places and others

- Q:Board PVC plastic floor plastic toxic

- Plastic floor is another name for PVC flooring. The main component of PVC material, PVC floor can be made into two kinds, one is homogeneous, is from the bottom to the pattern material is the same. There is a composite type, is the top layer is a pure PVC transparent layer, the following with the printing layer and foam layer. "Plastic floor" refers to the use of polyvinyl chloride materials production floor. PVC floor is widely used in all aspects of home and business because of its rich color and variety of colors.

- Q:PVC plastic floor construction costs a square meter

- 10-35 yuan with the tape [interface agent to glue the self leveling,] the specific price to see the construction site set

- Q:What is the home improvement PVC plastic floor

- Printing film: imported printing layer and the printing layer produced by the domestic production of the color and fidelity is very good, and the general production of small printing layer is prone to fade. Consumers in the purchase of the best looking for a high degree of integrity of the business to buy, so as not to fade the color of the plastic floor, the impact of beauty. Wear resistant layer: due to the different manufacturers, the quality of the wear-resistant layer is also a big difference, the poor quality of the wear-resistant layer in addition to easy cracking is also easy to shrink, resulting in the edge of the floor. Also recommend consumers to find a high degree of integrity of the business to buy PVC floor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood Plastic Composite Decking / WPC Board / wpc decking

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords