Window Grills Design for Sliding Windows/Sliding Window with Grille/grill Window

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

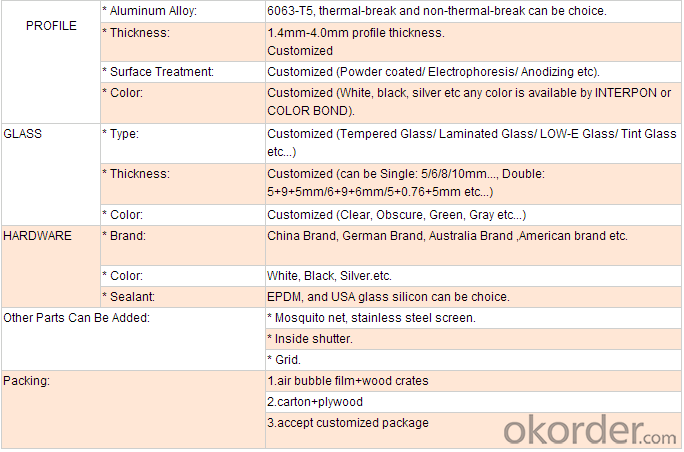

1. Profile:

A. Alloy: Aluminum 6061,6063

B. Temper: T5

C.Wall thickness: 1.2mm--2.0mm. or as client's demand

D. Surface treatment: Powder coating, Anodizing, Electrophoresis, Wood-grain with any color

E. Color: White or customized. F. Lengh: According to clients' needs.

G. Function: Security, Heatproof, Waterproof, Decoration, Airproof.

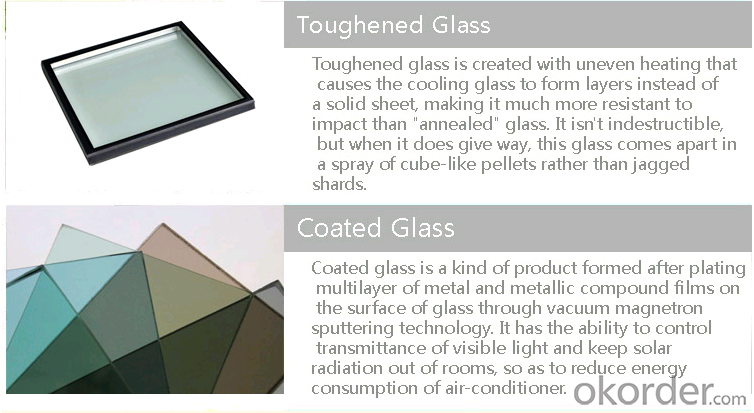

2. Glass:

A. Thickness: Double glazing glass 5mm+6A-19A+5mm.

B. Laminated glass: 5mm+0.38/0.76+5mm.

C. Any other glass thickness according to customer's requirement.

D. Special: Low-e/ reflective/tempered/float.

E. Color: According to clients' needs3. Hardware: High quality products made in China or other international brand as per customer requirment

4. Accessories:

A. Use Glass Silicone / Use Glazing Rubber.

B. Stainless steel accessories.

5. Production standard:

Make According To Customer's Detail Requirements.

6. Advantages:

A. Space saving, easy operating, easy to install and clean.

B. Good water-proof, fire proof, heat&sound insulations.

C. Economical and easy to maintenance.

D. High decay resistance.

E. High aging/ultraviolet/resistant.

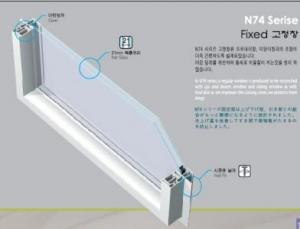

PRODUCT SPECIFICATION

Aluminium Glass Windows And Doors Advantages:

1.Broad open space.High-quality hardware system allows for smooth opening,and security.

2.Excellent sealing performance brings you more clean space,and saves energy.

3.Unique design of the drainage system can prevent entry of rain and dust.

Aluminium Glass Windows And Doors Characters:

1.Sound insulation 2.Rainproof 3.Heat insulation

4.Easy cleaning 5.Resistance wind 6.Anti-thef

7.Easy installation and durable finish 8.Rust proof nature

9.Anti abrasive properties 10.Accurate dimensions

11.Corrosion resistance 12.Overall strength

Feature

60mm profile series capable of both outward and inward opening for windows

Multi-chambered profile designed for effective thermal and acoustic insulation

Optimal wall thickness designed to ensure durability and safety for glass installation

Inboard Eurogroove designed to enhance security measures

Design optimization of reinforcement chamber for resistant performance to high wind pressure

Internally glazed for added security

Dual compression seals between the frame and sash provide optimal energy saving and ensure against water and dust penetration and air infiltration

Material formulated to undertake severe climatic conditioned regions

Glazing possibility of thickness from 5 mm to 33mm

The steps of window construction:

Aluminum or PVC (UPVC) window is being made from Aluminum or UPVC profile, window accessories and glass.

To produce an Aluminum or PVC window you have to do the following steps:

Cut the profiles (Aluminum or uPVC Profile, reinforcement and Glazing bead)

Put reinforcement profile inside the uPVC profiles

Screw reinforcement profile into PVC profile

End mill the mullions

Open holes for door handles, sash fastener channels and espagnolette

Weld uPVC profile or Crimping Aluminum profile

Clean the welded corners of uPVC windows

Assemble window

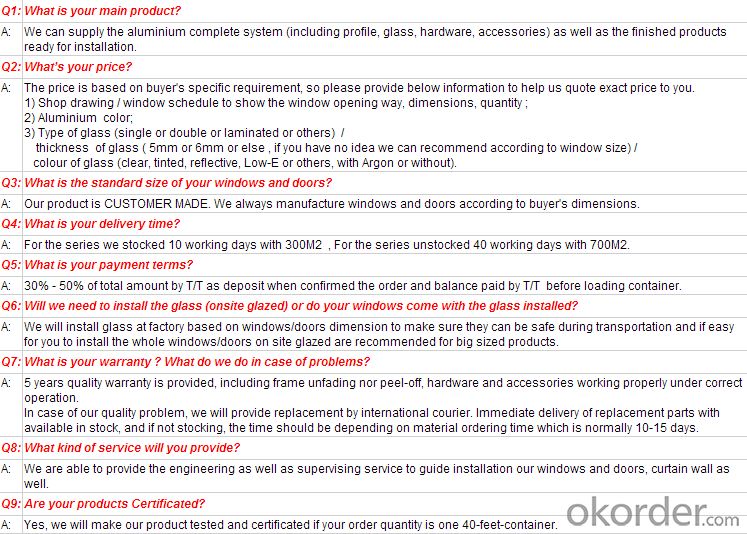

FAQ

- Q:I try to get paint of my caravan windows but it didnt work with stripper. any other suggestions.

- Mineral Spirits

- Q:I accidently put window paint on the back window of my friend's convertible. Now he says its stained, I really need to get it off. Any ideas?!

- problematic water stains are hassle-loose in city water structures . I somewhat have stumbled on in case you wash your vehicle in a degreaser, then dry with a drying fabrics like an Absorber . thoroughly do away with the water out of your living house abode windows and physique. Then use a cleanser wax in liquid style like mothers, or black ice. this eliminates the inital hardwater stain ,then use a carnuba wax like mothers or black ice. basically do small aspects of the vehicle at a time like 0.5 the hood or fender as dried wax is greater stable to do away with.the carnuba wax seals the paint from contamints and provides you an superb shine . now for the living house abode windows use a foaming window cleanser like invisable glass as this is composed of amonia and is danger-unfastened for tint.

- Q:I tried cleaning my plastic windows in my truck with water thinking if i wiped it up right away it wouldn't leave any spots but it did... I'm not trying to buy anything expensive and I was under the impression you don't use windex on plastic... Any ideas?

- If they are actually Lexan or Plexiglass the best thing i have found is Lemon Pledge furniture polish.I kid you not...the stuff works great.That's all i use on my motorcycle windshield.

- Q:When is it ok to take the plastic off my windows for summer? (the weatherization plastic that you blow-dry tight in the fall) I want some fresh air in my house but am not sure if it's the right time yet. I live in upstate NY.

- When you know you'll be comfortable in the house without the plastic on the windows. Some people are comfortable when the weather gets into the 50's, some at other temperatures.

- Q:I am looking for the plastic parts / clips that attach the glass pane to the cables of my car's window regulator. I can't find them individually. Specifically, I need them for Audi, BMW or Volkswagen (VW). Thanks

- I can find that sell the window regulator clips individually. They have them for Audi, Volkswagon, BMW and other makes as well. If you are going to fix it yourself, they also have a tutorials section, including video guides.

- Q:My windows seem to be extra drafty this year... It seems like one of them is open, but I can't find anything wrong with them. Anyhow, my heat is kicking on like every 15 minutes! I don't wanna get a $300 gas bill every month till winter is over... I'm thinking about putting plastic up on the windows --- How do I do this? What do I use?It seems so ghetto, but oh well.I live in an apartment building too btw..

- just google DIY shrink for window for information. it should help a lot ;even if you could not feel a breeze. It would be like having a thermal /multi pane window. do it to all your windows.

- Q:I'm about to move into an apartment room that I have been warned gets very cold in the winter (I live in MN). However, the person telling me this also mentioned that the windows had not been plastic wrapped the previous winter. In her opinion, however, plastic wrapping the windows would do no good because according to her quot;you can actually feel the cold coming up through the floor.quot; I think it's possible though that what she felt coming in through the floor was actually the drafts from the window sinking to the ground and spreading. Would plastic wrapping my windows eliminate this problem? Or would the room still be cold/I should request a different one? Thanks

- The glass itself? No. It needs an air barrier between the plastic and the window.. So basically you put plastic on the sill and walls, covering the window over all, and yes, that does work. I do it on my bathroom window during winter. Because it gets freekin' cold. Nobody likes taking a hot shower, then walking out of it nude in to Antarctica..

- Q:We live in an old, very poorly insulated house, and it's very drafty/cold during the winter. We've tried two-sided insulating tape that you put in the window sills, caulk strips that you put around the frame, etc. and none of it works. Is it worth the money to buy the plastic that you can put over the outside of your windows? The draft seems to be coming from where the window itself meets the sill, but also around the perimeter of the window (where the edging/molding is attached to the wall). I've read a few articles online about quot;how toquot; install plastic, but they all say that the plastic comes in kits and you need to attach it with the included double sided tape to your wooden window frame. our house is brick and there's not much of a frame outside. What little wood there is has been painted over many times, and I doubt tape would stick to it. Should I try to do it anyway? Is it worth the cost?

- Carefully remove the decorative molding from around the window.(inside) Then either stuff fiberglass insulation in the crack between the window and the jam. Or use the foam insulation in the can. Then replace the molding. A lot of people put plastic on their windows using staples

- Q:Can YOUHOOS at Yahoos give me an idea where I can find a sheetof heavy clear/ or even transparent plastic to put over my window thatnot like this cheap garbage I used from Frost King at home depot.. The last stuff came from a roll and was heavy duty and I don't need a roll of it, I'm just drawing a blank here. And this boxed up stuff sold in cheap discount stores really is garbage 1 mil junk.. Oh, and yes, this is their outdoor stuff , not the shrink indoor kit.... The window is about 4 ft x 6 ft..... 1950 era.....(hence the need for plastic ). I've got a few smaller as well... Thank You hoos....

- I am not sure why everyone is saying things like plastic and duct tape! I am sure that would not make for a beautiful awakening and definitely not much of an eye candy from inside or out! Like Carol Q was saying, you can purchase caulking, that is all good. However, you can also purchase rolls of window and door insulation strips. Works great! You can also purchase a spray bottle of foam insulation for your outlets or any cracks that you feel a draft coming from. If your windows are really outdated, you may have to go with plastic OR invest in one window at a time (if ya need) for better/thicker windows. Insulation above your room and around you room in the walls is also very important if you really want the freezing (lol) to end. Good Luck and stay warm!! ( keep your robe, hairdryer, and or electric blanket in bed at all times. lol jk.)

- Q:spruce up by stenciling on them. What sort of pre-clean should I do and what sort of paint will stick to a heavy plastic blind?

- Blind or shade? Wash with TSP if its a blind, and use any paint you want, preferably stencil paint. Forget it if it's a shade. Paint will not stick to flexible plastic permanently

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Window Grills Design for Sliding Windows/Sliding Window with Grille/grill Window

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords