wholesale H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

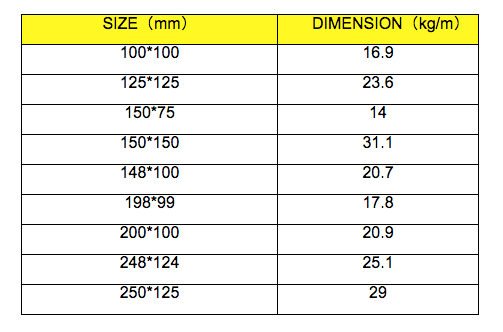

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:How do steel H-beams perform in terms of buckling resistance?

- Steel H-beams generally have excellent buckling resistance due to their shape and structural properties. The combination of a compact cross-section and the distribution of material along the flanges and web allows H-beams to withstand high compressive loads without buckling. Additionally, the use of high-strength steel further enhances their buckling resistance, making these beams a reliable choice for various structural applications.

- Q:What are the different methods of installing steel H-beams?

- There are several methods of installing steel H-beams, including using a crane to lift and position the beams into place, welding the beams together on-site, bolting the beams together, or using specialized connectors or brackets to secure the beams in position. The specific method chosen depends on the project requirements, accessibility, and structural design considerations.

- Q:How do steel H-beams compare to concrete beams in terms of construction speed?

- Steel H-beams are generally faster to construct compared to concrete beams. This is primarily due to the nature of steel as a material, which allows for easier and faster fabrication and assembly. Steel H-beams can be prefabricated off-site, allowing for efficient mass production and faster delivery to the construction site. In contrast, concrete beams require more time for construction. The process involves multiple steps, such as formwork installation, pouring and curing of the concrete, and removal of the formwork. These steps take time to complete, and the curing process alone can take several days or even weeks, depending on the size and complexity of the beams. Moreover, steel H-beams are lighter in weight compared to concrete beams, making them easier to handle and install. This results in reduced labor requirements and shorter construction timelines. Additionally, steel beams can be easily adjusted or modified on-site, allowing for faster adjustments during the construction process. Overall, steel H-beams offer significant advantages in terms of construction speed compared to concrete beams. Their prefabrication capabilities, lighter weight, and ease of installation contribute to faster construction timelines, ultimately saving time and costs in the construction process.

- Q:Can steel H-beams be used for pedestrian bridges over highways?

- Yes, steel H-beams can be used for pedestrian bridges over highways. Steel H-beams are commonly used in bridge construction due to their high strength and durability. They provide structural support and can withstand heavy loads, making them suitable for pedestrian bridges over highways. Additionally, their flexibility allows for various design possibilities, ensuring the safety and stability of the bridge.

- Q:How do steel H-beams perform in areas with high humidity and saltwater exposure?

- Steel H-beams can perform well in areas with high humidity and saltwater exposure as long as they are properly protected against corrosion. The high humidity and saltwater can create a corrosive environment that can cause steel to rust and weaken over time. However, steel H-beams can be coated with protective finishes or galvanized to enhance their resistance to corrosion. These coatings act as a barrier between the steel and the corrosive elements, preventing direct contact and reducing the risk of rust formation. Regular maintenance and inspections are also essential to ensure that any damage or deterioration is identified and addressed promptly. By taking these precautions, steel H-beams can effectively withstand high humidity and saltwater exposure in a durable and reliable manner.

- Q:Are steel H-beams resistant to rot or decay?

- No, steel H-beams are not resistant to rot or decay. Unlike wood, steel does not rot or decay, as it is not an organic material. Steel beams are made from iron with varying amounts of carbon and other elements, which gives them their strength and durability. However, it is important to note that while steel beams are not prone to rot or decay, they can still corrode over time due to exposure to moisture and other environmental factors. To prevent corrosion, steel beams are often coated with protective layers, such as paint or galvanization, which helps to extend their lifespan and maintain their structural integrity.

- Q:What are the considerations when designing for thermal bridging in Steel H-Beams?

- When designing for thermal bridging in steel H-beams, there are several considerations that need to be taken into account. Firstly, it is important to understand that steel is a highly conductive material, meaning it conducts heat more effectively compared to other building materials such as wood or insulation. This makes steel H-beams prone to thermal bridging, which is the transfer of heat across a solid structure, resulting in heat loss or gain. To mitigate thermal bridging in steel H-beams, one consideration is to provide a thermal break. This involves incorporating a layer of insulation between the steel beam and the surrounding components. The insulation acts as a barrier, preventing the transfer of heat and reducing thermal bridging. Various materials can be used for thermal breaks, such as rigid foam insulation or specially designed insulating materials. Another consideration is the overall design of the building envelope. By optimizing the insulation levels and minimizing the number of steel H-beams in areas of high thermal importance, the potential for thermal bridging can be reduced. Proper placement and sizing of insulation around the beams can also help in minimizing heat transfer. In addition, careful detailing and construction practices are crucial when designing for thermal bridging in steel H-beams. It is important to ensure that the insulation is installed properly and fully covers the steel beams, leaving no gaps or voids that could compromise the thermal performance. Proper sealing and weatherproofing of the building envelope is also essential to prevent air leakage, which can exacerbate thermal bridging. Lastly, it is important to consider the long-term durability and maintenance of the thermal solution. The chosen insulation materials should be durable, resistant to moisture, and able to withstand the potential stresses and movements of the steel beams. Regular inspections and maintenance should be carried out to ensure that the insulation remains intact and in good condition. Overall, by considering the thermal properties of steel H-beams and implementing appropriate design strategies, it is possible to minimize thermal bridging and improve the energy efficiency of a building.

- Q:What are the specifications for H steel HW, HB, HN?

- HW is a H type steel flange height and width substantially equal; mainly used for reinforced concrete frame column steel column, also known as rigid steel column; column is mainly used in steel structure.

- Q:What are the different span lengths achievable with steel H-beams?

- The achievable span lengths of steel H-beams can vary depending on several factors, including the beam's size and weight, the load it must support, and the project's specific design requirements. However, in general, steel H-beams can achieve span lengths ranging from a few feet to several hundred feet. For smaller residential or commercial projects, H-beams with span lengths of 10 to 20 feet are commonly utilized. These beams can effectively support typical loads like floor joists, roof trusses, or small bridges. In larger industrial or infrastructure projects, longer span lengths are necessary, and therefore steel H-beams with much greater lengths are employed. In such cases, the beams can be designed to span over 100 feet or even several hundred feet, allowing for the construction of large-scale structures such as warehouses, factories, bridges, or high-rise buildings. It is important to consider that achieving longer span lengths with steel H-beams may require additional structural supports, like columns or piers, to ensure the beam remains stable and can bear the load. Additionally, the involvement of professional structural engineers and architects in the design process is crucial to ensure that the chosen beam size and span length are suitable for the specific project requirements and meet safety standards.

- Q:How do you calculate the moment capacity of steel H-beams?

- To calculate the moment capacity of steel H-beams, you need to consider the properties of the beam, including the dimensions and material properties. The moment capacity, also known as the bending strength or flexural strength, is a measure of the beam's ability to resist bending forces. The moment capacity of a steel H-beam can be calculated using the following steps: 1. Determine the section properties: The first step is to calculate the section properties of the H-beam, such as the moment of inertia (I) and the section modulus (Z). These properties depend on the dimensions of the beam, including the flange width, flange thickness, web height, and web thickness. These properties can be found in structural design manuals or obtained from the manufacturer's specifications. 2. Determine the yield strength: The next step is to determine the yield strength (Fy) of the steel material used in the H-beam. This value represents the maximum stress that the steel can withstand without permanent deformation. The yield strength can also be obtained from design manuals or manufacturer's specifications. 3. Calculate the plastic moment capacity: The plastic moment capacity (Mp) is the maximum moment that the beam can resist before it starts to yield (plastic deformation). It is calculated by multiplying the yield strength (Fy) by the section modulus (Z). The formula for calculating the plastic moment capacity is Mp = Fy * Z. 4. Determine the allowable moment capacity: The plastic moment capacity is not always the limiting factor in design. Depending on the design requirements and safety factors, the allowable moment capacity may be lower than the plastic moment capacity. The allowable moment capacity is calculated by multiplying the plastic moment capacity by a factor of safety (Fs). The factor of safety accounts for uncertainties in materials, loads, and other design considerations. The formula for calculating the allowable moment capacity is Ma = Mp * Fs. By following these steps, you can calculate the moment capacity of steel H-beams and ensure that the beam is designed to withstand the required bending forces in a safe and efficient manner. It is important to consult design codes, standards, and structural engineering principles to ensure the accuracy and reliability of the calculations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

wholesale H Beam Profile with Grade A Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords