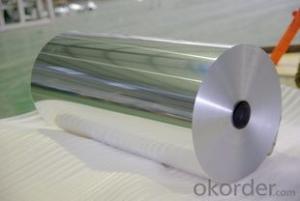

Wholesale aluminum foil, don't miss it!

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Secification:

Alloy : AA1235/1050/1060/1100/3003/8011/8006/8079/8021etc.

Temper: H14/16/18/22/24/26, HOetc.

Thickness: 0.006mm—0.20mm

Width: 200mm—1600mm(Can be slitted)

Coating : HSL/Primer

Color : Accordingto customers’ requirements

Feature:

100% safe

Environmentally friendly, recoverable and recyclable

Used for storing, packing, grilling/ baking, heating andfreezing

Customized orders available

High-temperature sterilization

Aplication:

Food Packing, Household Application, Cigarette Packing,Lamination, Medicine , Printing, Heat Sealing, Beer Packing, RoofInsulation Materials, Honeycome Materials and so on.

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

40 day after client’s deposit

- Q:ok I recently got a keurig and I chose it over tassimo because I can still use my normal canned coffee if I run out of discs however the t discs are cheaper where I live and they have some blends keurig doesn't offer that I like so I was wondering if anyone has tried opening t discs and dumping them into a my k cupI haven't been able to find the details of the inside of t discs and buying a whole pack to just open one is not vey logical to me so any help would be amazing

- the micro waves reflect off the metalit's not good but it's not that big of a deal in my opnionMetal will not explodeThe reflecting waves might cause sparks and the microwave to blow out but it's not going to cause an explosion.

- Q:Can someone explain to me what the difference a airsoft gun is from a paintball gun or a bb gun?

- VENISON OR BEEF JERKY 3 lbvenison or beef Select lean cuts of meatRemove any fat around the edgesFlank steak, brisket or round steak can be usedI use both front shoulders from deerFor greatest tenderness slice very thinly, against the grain and cut into strips, no more than 1/4 inch thickThe following recipe is for about 3 pounds of meatI don't weigh or measure, I approximateMarinate for at least 12 hours, the longer the betterAfter meat has marinated blot dry with paper towelsMARINATE: 3 tbspsoy sauce 4 tbspWorcestershire sauce 1/8 tspcayenne pepper Pinch of white pepper 1/8 tspblack pepper 1/4 tspgarlic powder 4 tbspteriyaki sauce Hickory liquid smoke (to suit taste) Hot sauce (to suit taste) Pork sausage seasoning (to suit taste) Onion powder (to suit taste) 3 cjuice drained from banana peppers Do Not use salt! Combine all ingredients, blend wellAdd meat, stir at least twice during marination.

- Q:is the freezer paper is the same as the aluminium paper?? anyone knows what other brand beside freezer paper - reynolds

- I get this stuff from the pet section called Kids and Pets, it's a red and white bottleIt has enzymes that break down the urine and make it disappearIt also works on tough stains like blood, etcYou just spray it on and let it sitThen later you wipe it down.

- Q:What get's hotter in the sun black or aluminum foil?Need to pick materials for a solar cooker, Which one gets hot and releases it to cook the food.

- For a solar cooker, black paper absorbes a lot of heat but doesnt release it aluminum foil reflects all the heat into the food hope it helped :) id go with aluminum for sure

- Q:We had our basement finished about 2 years agoToday there is a really strong odor down there, I think it may be a burnt wire smell, but I'm not exactly sureIt almost smells kinda chemicallyAnyway, we have dome lights on the ceiling down there, each with 2 bulbsThey should be 60 Watts each, however we found a 100 watt bulb in one today and the coating on the wires around it were all burntIt's been a few hours since we changed all of the bulbs, but the smell is still very strongAnyone have an idea of what it could be?Also, our light fixtures have a sheet of what looks like aluminum foil that is supposed to lie flat against the top of the fixtureIt has holes cut out where all the wires need to go throughDoes anyone know why this is in there and if it may be removed?Thank you!!!

- The foil sheet is a heat barrier and needs to stay where it isThe 100 watt bulbs have probably fried the insulation on the wires in the fixturesYou should rewire or replace the fixtures is the insulation seems brittle or looks burntThe reason for the 60 watt maximum is because of heat more than loadThe added heat from the 100 watt bulbs probably cooked the wiring.

- Q:My newly adopted jack russell mix is 10 months old, and I've only had him 3 weeksHe is scared of any and all new things and situations, and it's apparent he wasn't socializedBut he usually warms up to things after about 5 minutes of checking it outI'm having problems when I take him out to poopWhen I go to retrieve a baggie or toss a used bag in the quot;pet stationquot; ( a metal pole with a bag dispenser and a trash can) of my apartment complex, he balks and won't walk with in 20 ft of itThis happens every time, and I don't know what to doIf I try to tug on his harness to get him to move, he just tries to back out of itInvariably I end up scooping him up and walking up to it to get the job doneAny suggestions what is causing this and what I could do differently?

- Very and not for the beginnerShould be done by a qualified contractor.

- Q:Im loosing weight, 10 bs so far :) Working out everyday and and watching my carb and calorie intakeIve been eating broccoli, tuna, half a turkey and cheese sandwich and Im getting SO BORED with it.any other small easy lunch ideas ?? thanks :)

- Get your favorite veggies.broccoli, cauliflower, zucchini, onion, carrots etc and cut them up into larger/bite size piecesYou can either stirfry or bake themTo stirfry: Put 1/2 cup of water in a skillet with the veggies and cook on 7 or 8 heat til they're as soft as you likeThe water will cook out, it's just to keep the pan from getting too dry and the veggies burningOnce the veggies are to where you want themAdd 11-2 tablespoons of soy sauce for flavor and cook for another 4-7 minutesYou can also put them on a little brown rice if you'd like or mix them with stirfried chickenTo do this, you can either use 1 tablespoon of olive oil or just non-stick spray in the skillet, cut the chicken breast into pieces and cook til doneRemove the chicken from the skillet, cook the veggies as stated above and re-add the chicken when you add the soy sauce - I just had stirfried veggies (1 1/2 cup broccoli, 1 1/2 cup cauliflower and 3/4 cup carrots with 2 tablespoons soy sauce) for lunch and it was only 197.5 caloriesJust to give you an idea of how many calories something like that would beYou can also bake the veggiesFirst, after you've cut up the veggies, put them in a baggie with 1-2 tablespoons of olive oil and salt and pepper as you like and shake until well coatedMake a pouch-like thing out of aluminum foil and pour the veggies in and wrap the topBake for 20-25 minutes at 300Pull them out and open the aluminum, then put under the broiler for 5 minutes at a low heat (around 2 or so) and it'll be good to go.

- Q:My first time making some ribs and I wanted to know how long should I leave them in the oven and how high the temperature should beAlso, how often should I check up on them ?

- Not knowing what your surface looks like I don't know if this would work, but I used to have to drill larger holes in electrical enclosures and if I had to center and drill a larger diameter I would first drill the diameter hole I needed with a hole saw in a chunk of dense wood at least an inch and a half thick, then clamp the wood tightly to the surface I needed to drill using spring-jaw welding clamps, with the wooden hole centered over the existing smaller holeThe wooden hole acted as a guide to keep the drill centered as I drilled the new perimeter around the existing hole If it's a part you can remove from the vehicle and take to a machine shop, they would be able to drill it for youI would have recommended a Klein Unibit but unfortunately they only go up to about 35mm (and buying one would probably be more costly than paying the machine shop.)

- Q:I recycle and like everyone, when I recycle glass and plastics, labels/aluminum lids are also put into the same bin along with paper and plasticsDo they seperate out that paper and aluminum when recycling the glass and plastics? Or do they just recycle it all together? Does this have a negative effect on the recycling process?Thanks in advance!

- Refractory brick, also known as fire brick, is a type of specialised brick which is designed for use in high heat environments such as kilns and furnacesNumerous companies manufacture refractory brick in a range of shapes, sizes, and styles, and it can be ordered directly through manufacturers or through companies which supply materials to people who work with high heat processing of materialsHigh quality refractory brick has a number of traits which make it distinct from other types of brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholesale aluminum foil, don't miss it!

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords