Wholesale 201 Stainless Steel Sheet Embossed Sheets Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Stainless steel which can be produced in different chemical, physical and mechanical properties, have high corrosion and heat resistance, mechanical strength, manufacturing ease, aesthetic appearance hygienic and long lasting properties.

STANDARDS

ASTM A240/A240M,ASME A240/A240,EN 10088-2, EN10028-7,JIS G 4305

| Decoration Stainless Steel Sheet / Plate | |

| Size | Thickness 0.02mm-3mm, Width and Length can be customized |

| Grade | SUS 201, 202, 304L/H, 316L/H, 321/H, 317/H, 347/H, 310S, 430, 409/L, 31803, 32750, 32760, etc |

| Standard | JIS,EN,ASTM,AISI |

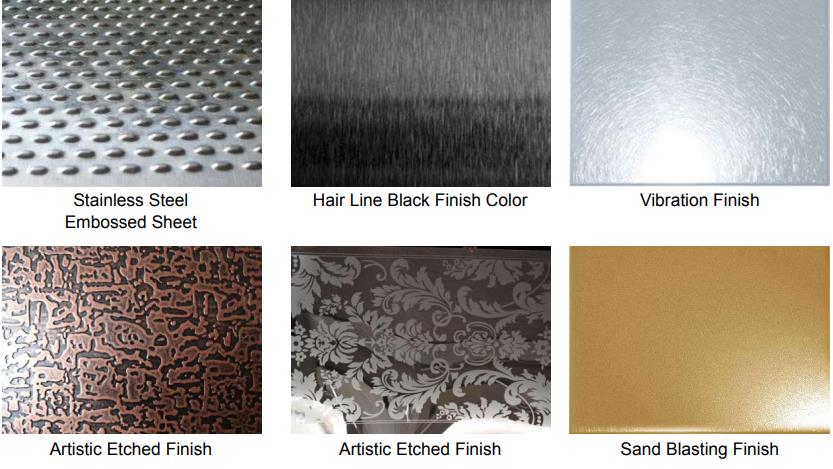

| Finish | 2B, HL, NO.4, BA, Mirror, Embossed, Colored, Vibration, Sand blasting, Artistic etched etc. |

| Application | Elevator, Carbin Decoration, Building Decoration, Architectural Decoration, Kitchen Decoration |

Stainless Steel Sheet Series

Stainless Steel Polished Sheet (8K Mirror, Hairline, Grit 240,320)

Embossed Stainless Steel Sheet

Etched Stainless Steel Sheet,

PVD Colored Stainless Steel Sheet,

Perforated Stainless Steel Plate

Chequered Stainless Steel Sheet

Packaging & Shipping

Application

Kitchen, Subway, Hospital, Door, Frame of Door, Structure, Machine, Pipe, Utensil, Internal Decoration of Elevator.

- Q:What is the difference between stainless steel sheets and stainless steel plates?

- The main difference between stainless steel sheets and stainless steel plates lies in their thickness. Stainless steel sheets are typically thinner, with a thickness ranging from 0.4mm to 6mm, while stainless steel plates are thicker, with a thickness starting from 3mm and going up to several inches. Additionally, stainless steel plates are often used for structural purposes or heavy-duty applications, while stainless steel sheets are commonly used for decorative purposes, cladding, or smaller projects.

- Q:How do you prevent scratches or dents on stainless steel sheets?

- To prevent scratches or dents on stainless steel sheets, there are a few measures you can take: 1. Handle with care: When handling stainless steel sheets, be cautious to avoid dropping or dragging them against rough surfaces. Use gloves or protective gear to minimize the risk of scratches caused by sharp objects or tools. 2. Clean with soft materials: To prevent scratches during cleaning, use soft cloths or non-abrasive sponges. Avoid using steel wool or harsh cleaning agents that can damage the surface. Additionally, always wipe in the direction of the grain to maintain the stainless steel's appearance. 3. Use protective films or sheets: Applying a protective film or sheet to the stainless steel surface can provide an extra barrier against scratches or dents. These films are typically adhesive and can be easily removed once the stainless steel sheets are installed. 4. Store properly: Store stainless steel sheets in a clean and dry environment to prevent scratches or dents caused by contact with other objects. Avoid stacking sheets directly on top of each other without any protective barrier in between. 5. Invest in edge protectors: Stainless steel sheets are often susceptible to dents or scratches on their edges. Using edge protectors or corner guards can help prevent damage during handling, transportation, or storage. By following these preventive measures, you can significantly reduce the chances of scratches or dents on stainless steel sheets, ensuring their longevity and maintaining their pristine appearance.

- Q:What is stainless steel AB board, please?

- The BA board is not used for drawing purposes, if it is drawing, put fine timber to petty use is wasted.

- Q:Can stainless steel sheets be used in outdoor environments?

- Yes, stainless steel sheets can be used in outdoor environments. Stainless steel is highly resistant to corrosion, making it a suitable choice for outdoor applications where exposure to moisture, humidity, and other environmental elements is likely.

- Q:How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, there are a few common methods you can consider: 1. Adhesive: Using a high-strength construction adhesive specifically designed for metal bonding, apply it to the backside of the stainless steel sheet. Press the sheet firmly against the wall and hold it in place until the adhesive cures. This method is suitable for smaller, lightweight stainless steel sheets. 2. Screw fasteners: Drill holes through the stainless steel sheet and into the wall at regular intervals. Use stainless steel screws that are appropriate for the thickness of the sheet and the wall material. Insert the screws into the holes and tighten them until the sheet is securely attached to the wall. This method works well for larger and heavier stainless steel sheets. 3. Magnetic mounting: If the stainless steel sheet is magnetizable, you can use magnets to attach it to a metal wall. Place strong magnets on the backside of the sheet, aligning them with the corresponding magnets on the wall. The magnets will hold the sheet in place, allowing for easy installation and removal. 4. Panel mounting systems: Some manufacturers offer panel mounting systems specifically designed for stainless steel sheets. These systems typically consist of brackets or clips that attach to the backside of the sheet and then hook onto a track or rail system mounted on the wall. This method provides a secure and visually appealing attachment solution. When attaching stainless steel sheets to a wall, it's important to ensure that the wall surface is clean, dry, and properly prepared. This will help optimize the adhesion and prevent any potential issues. Additionally, always follow the manufacturer's instructions and guidelines for the specific method or product you are using.

- Q:What type of welding rod is used for 304 stainless steel plate welding?

- A102 is Cr19Ni10 stainless steel electrode titanium calcium type coating, corrosion resistance of the deposited metal has good mechanical properties and resistance to intergranular, has excellent welding performance and anti porosity property, anti cracking, red medicine Pinai. A107 is a Cr19Ni10 stainless steel electrode with alkaline coating. The deposited metal has good mechanical properties and intergranular corrosion resistance. Therefore, they are aimed at 304 development of welding electrodes.

- Q:Can stainless steel sheets be used for filtration applications?

- Yes, stainless steel sheets can be used for filtration applications. Stainless steel is known for its corrosion resistance and durability, making it an excellent choice for filtration systems. The sheets can be formed into various filter elements, such as screens, discs, or cartridges, to suit different filtration needs. Stainless steel sheets offer high mechanical strength, allowing them to withstand high pressures and temperatures without deformation. Additionally, stainless steel can be easily cleaned and sanitized, making it suitable for applications where hygiene is crucial, such as in the food and beverage industry. Overall, stainless steel sheets are widely used in filtration applications due to their excellent performance and reliability.

- Q:Can stainless steel sheets be used in construction projects?

- Indeed, construction projects can make use of stainless steel sheets. Stainless steel, a versatile and sturdy material, finds widespread application in various construction scenarios. Its reputation for corrosion resistance renders it suitable for outdoor and high-moisture settings. Buildings often employ stainless steel sheets for roofing, wall cladding, structural elements, and decorative aspects. Moreover, they serve interior purposes like countertops, backsplashes, and elevator panels. Furthermore, stainless steel sheets come in diverse finishes and textures, enabling customization and enhancing aesthetic charm in construction endeavors.

- Q:How do you remove adhesive residue from stainless steel sheets?

- To remove adhesive residue from stainless steel sheets, you can use various methods such as applying rubbing alcohol, vinegar, or a commercial adhesive remover. Start by soaking a cloth or paper towel in the chosen solution and gently rubbing the residue until it loosens. If needed, use a plastic scraper or your fingertips to carefully scrape off the remaining adhesive. Once all residue is removed, clean the stainless steel surface with warm soapy water and dry it thoroughly.

- Q:What is the elongation percentage of stainless steel sheets?

- The elongation percentage of stainless steel sheets can vary depending on the specific grade and thickness of the material. Generally, stainless steel sheets have a moderate elongation percentage, typically ranging from 40% to 60%. However, certain grades of stainless steel with higher nickel content, such as austenitic stainless steel, can exhibit greater elongation percentages, often exceeding 60%. It is important to note that elongation percentage is a measure of the material's ability to deform plastically before fracturing, indicating its ductility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholesale 201 Stainless Steel Sheet Embossed Sheets Plates

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords