Whole Aluminum Formwork System For Large Area Slab Formwork System

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

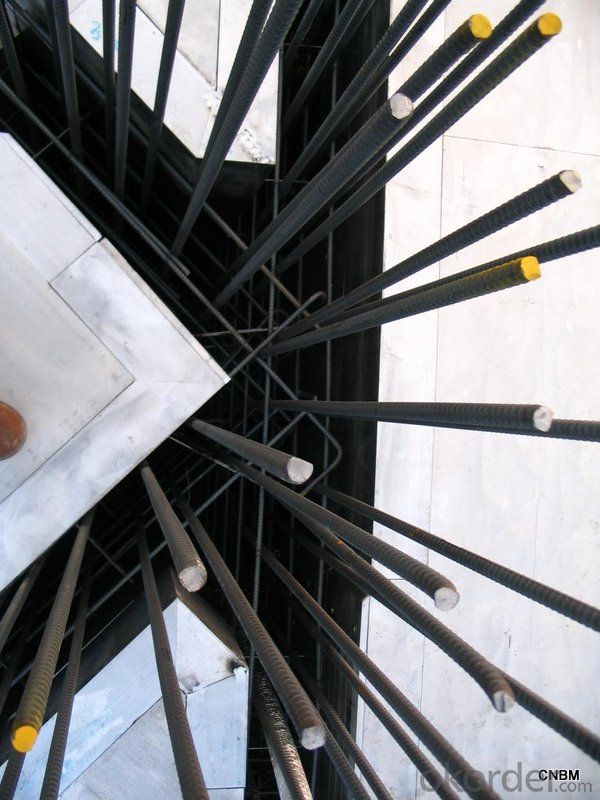

3. Whole Aluminum Formwork Images

4. Whole Aluminum Formwork Specifications

1: MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2: DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3:StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4:StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

.We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

-Packing: wood package and adhesive tape

-Shipping: by sea

-Shipping time: Normally small orders just takes 7 business days to arrive your hand;. When it comes to the customs declaration, it may need 2weeks.

Ten superiorities in Aluminum Formwork

1.Environmental Protection.

2.Low using cost.

3.Saving labor & Easy installation.

4.Fast speed of construction.

5.Recycling 300 times.

6. High stability and load bearing capacity.

7. Safety & convenience.

8. Recovery of high value.

9. Strong versatility.

10. Precision design & compact joint.

Introduction of Aluminum Formwork System

| Material | 6061-T6 Aluminum alloy |

| Main Components | Wall |

| Beam | |

| Column | |

| Prop | |

| Others | |

| Applications | Exhibition setup |

| Interior refurbishing | |

| All the towers can be connected together for multi-purpose | |

| Yield strength | ≥30KN/m2 |

Size | Non-standard, custom-made as per buy's request |

| Features | Easy to Handle |

| High Concrete Pouring Rate | |

| More Reuses | |

| Great Recyclable Value | |

| Environmental Friendly | |

| One-time Pouring |

- Q:What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- At present, other countries in the world, including international organizations, have not put forward the concept of equipment manufacturing. The concept of equipment manufacturing industry is unique to our country. Its formal appearance was seen in the central economic work conference in 1998, which explicitly stated: "we must energetically develop the equipment manufacturing industry."". (central economic work conference: Economic Daily, December 10, 1998, first edition) The core of the manufacturing industry is equipment manufacturing. People do not have the same understanding of equipment manufacturing industry, and there is no consensus definition and scope definition. It is generally believed that the manufacturing sector consists of the equipment manufacturing industry and the final consumer goods manufacturing industry. Equipment manufacturing industry is the general term of the industry which provides the production technology and equipment for the simple reproduction and extended reproduction of the national economy, namely the machine manufacturing industry for producing machines".

- Q:How are buildings, installations and materials divided?

- Provisions on the division of equipment and materials for engineering construction? [answer] the division of equipment and materials in engineering construction is directly related to the reasonable division of investment structure, budget preparation and calculation of construction output value. In order to reasonably determine the project cost, strengthen the investment in the process of construction and management, the equipment and materials in the engineering construction is unclear, especially the universal controversial common problems and put forward the principle of division of fifteen copies of "national unified installation project budget quota" of the equipment and materials are divided, the provinces, autonomous regions and municipalities directly under the central government and the relevant departments of the State Council, the Department should be combined with the local situation, formulate rules for its implementation, and report to the Ministry of construction for the record.

- Q:Where was the construction machinery conference held in 2015?

- Co organizer: BMW (Chinese) Engineering Machinery Company Limited, Shandong Lingong Construction Machinery Co, Limited by Share Ltd, Shantui construction machinery Futian leiwo international heavy industry Limited by Share Ltd, Shandong Chang Linzhu Machinery Group Limited by Share Ltd, Shandong rhinos Engineering Machinery Company Limited, Beijing Tianshun Hydraulic Technology Co., Ltd. Ji'nan the Great Wall Andy Machinery Co. Ltd., Langfang Deji machinery Polytron Technologies Inc, Tai'an Dongyue Heavy Industry Co. Ltd.

- Q:Where are the hanging baskets for the building?

- It is forbidden to take a stool or put a ladder on a hanging basket to work higher; it is not allowed to work alone in a basket, and no electric machinery or equipment can be placed in the basket;

- Q:Where are the mechanical pressurization air supply facilities set up?

- The purpose of setting up a mechanical pressurization air supply smoke prevention system is to provide evacuation routes and shelters without smoke interference in the event of a fire in the building. Therefore, in the closed door, pressing position, and the fire floor must maintain a certain pressure difference, the position of the air pressure value is a relative positive pressure); at the same time, in the open part of the pressure when the door can have enough air velocity in the opening section, to effectively prevent the intrusion of flue gas, the safety of personnel ensure evacuation and refuge.

- Q:What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ limited energy or hazardous substances: conditions of actual technical and economic constraints, some risk sources can not be eradicated, then they should try to limit with energy or hazardous substances, reduce the risk of. Reduce the amount of energy or dangerous substance.

- Q:Construction machinery production need to deal with what documents?

- Two, enterprise legal person business license (copy), with enterprise legal person business license duplicate copy, search three, all levels of safety production responsibility system and safety production rules and regulations directory and documents, operation procedures directory

- Q:What are the main functions of construction equipment monitoring system?

- The total of the console cameras and auxiliary equipment (such as camera, PTZ, shield) control generally adopts the bus mode, a control signal to the camera near the terminal in the terminal box decoding, decoding box will total console from the control signal encoding solution, a control action command signal, a variety of actions to go camera control and auxiliary equipment (such as lens zoom, pan rotation etc.). In the case of some cameras that are close to the control center, in order to save money, the command signal, which is the "on or off" signal, can also be sent directly by the console. In short, according to the composition of the system and requirements, can be considered in order to complete the overall console design requirements or order requirements.

- Q:What functions should be achieved in mechanical structure design?

- Mechanical structure design plays an important role in mechanical design. This chapter mainly discusses the characteristics, steps and mode of thinking of mechanical structure design. The working principle and design requirements of the machine assembly is a major factor in determining the structure and shape of the parts, followed by the selection of materials, manufacturing process requirements, which has the advantages of good manufacturability (processing and assembly). In addition, the perfection of the structure and shape of the parts has a great influence on the strength and stiffness.

- Q:What are the mechanical drawing software?

- The 3D map only contact with SolidWords and Pro/E, Pro/E is better than Solidwords in general, but Solidwords is very simple to use, see Help tutorials you can learn to draw a three-dimensional map is not particularly complex easily to estimate a few days is enough. But any one of the two kinds of software, want to do not understand the words, expert advice is not really easy. UG and MasterCAM haven't touched much, but I've heard that it's suitable for processing stereogram.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Whole Aluminum Formwork System For Large Area Slab Formwork System

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords