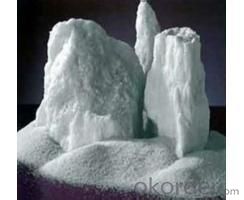

white fused alumina for refractory 99.2%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 25kg bag or ton bag or as your requirement. |

| Delivery Detail: | within 20 days delivery after receipt of advance payment. |

Specifications

99% high purity abrasive White fused alumina for refractory

1.White fused alumina99%

2.Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm

Products discription

1.Introduction

The main raw material of white fused alumina is high grade processed alumina, which is fused with the carbon material and scrap iron in the electic furnace under the high temperature of above 2200°C.The product is characterized by low expansion coefficient, high refractoriness, good thermal and chemical stability.

2. Grain size commonly used

Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm ,200#-0, 325#-0.

Abrasives: F24-F60.

Sandblasting abrasive:F10-F240.

Precision casting: F80-100, F100-F120.

Ceramic & electronic polishing:F240-800.

3.Physical properties of White Fused Alumina

Item | Color | Color System | Mohs Hardness | Melting Temperature(°C) | Refractory Temperature(°C) | True Density( g/cm3) | Magnetic Material |

Specification | white |

trigonal system | min10 | 2250°C | 1900°C | min3.50 | max0.003%

|

4.Chemical index of White Fused Alumina

Purpose | Specification | Chemical composition(%) | Magnetic material content(%) | ||||

Al2O3 | Na2O | SIO2 | CaO | ||||

For abrasive | F | 12#—80# | min99 | max0.6 | max0.4 | max0.003 | |

90#—150# | min98.5 | max0.003 | |||||

180#—240# | min98.2 | max0.7 | max0.4 | max0.002 | |||

For refractory | Size sand | 0—1mm | min99 | max0.5 | max0.4 | max0.003 | |

1—3mm | |||||||

3—5mm | |||||||

5—8mm | |||||||

Fine powder | 200#—0 | min98.5 | max0.5 | max0.5 | max0.003 | ||

325#—0 | |||||||

- Q:What are the features of construction class A fire resistant door ?

- Residential building: If the building height exceeds 100 meters, the combustion performance of thermal insulation material should be A level. Other civil building: Class A fireproofing material MCM should be set in buildings whose height is above 50 meters. National A level fireproof flexible?material is made up of soil, rock flour, sand, cement and other inorganic powder and modifying agent. Product density is 2327kg / m3. Upon examination, the combustion performance of the product meets A level requirements, and the additional classification meets s2, d0, t0 requirements. According to GB 8624-2006 sepcification, combustion performance of the product should reach A2-s2, d0, t0 level. Light, thin: 2-4mm thick / piece, saving space and cement, convenient to transport. : State Class A fireproof flexible?material. Freezing-thaw resistance: up to 100 freezing-thaw experiments (close to 100 years), the surface has no powder, no crack and no peeling. Aging and acid resistance: anti-aging property can reach more than 3500h, that is, it will not degenerate for 50 years. Recyclable: new energy, renewable , no "three wastes" emission

- Q:What are the physical properties of refractory material?

- The mechanical properties of refractory material include compressive strength, volume density and sclerosing, slag resistance, elastic modulus, thermal shock resistance, oxidation resistance, bibulous rate, fluidity, resilience, bond strength and slump, electrical conductivity, specific heat, heat capacity, the impact strength, linear change, torsional strength, stomatal aperture distribution, resistance to acid, etc. The use performance of refractory material include refractoriness, thermal emissivity, condensation, porosity, coefficient of thermal expansion. Thermal properties of refractory material include thermal conductivity, temperature conductivity, plasticity, the hydration resistance, creep performance. The physical properties of the refractory materials include structure performance, mechanical properties, shear strength, load softening temperature, CO erosion resistance. The structure properties of the refractory materials include porosity, alkali resistance and sintering. The operating performance of refractory material include consistency, tensile strength, the use performance and operating performance, wear resistance, bending strength, thermal properties.

- Q:What are the models of refractory cables?

- The models of refractory cables: NH-KVV22 copper core flame-retardant PVC insulated and fire retardant control cables with steel belt sheath NH-KVVRP copper core flame-retardant PVC insulated and fire retardant shielding control cables with steel braiding sheath NH-KVVP2 copper core flame-retardant PVC insulated and fire retardant shielding control cables with sheath and steel belt wrapping NH-KVVRP2 copper core flame-retardant PVC insulated and fire retardant shielding soft control cables with sheath and steel belt wrapping NH-KFF copper core fluorine plastic insulated and fire retardant control cables with sheath NH -KFFR copper core fluorine plastic insulated and fire retardant soft control cables with sheath NH -KFFP copper core fluorine plastic insulated and fire retardant shielding control cables with sheath and copper wire braiding

- Q:what's the varieties of fire-proof?sealing?material?

- Fire blocking material currently on the market include: fire stopping board, foam blocking material, flame resisting module, fire-resisting sealant, flexible organic caulking, WXY-II and fire retardant bag, etc. fire-proof?sealing?material is widely used in building construction and can ensure high-temperature flame and smoke from fires not spread to another fire?compartment, different buildings generally use different sealing methods. Pipeline is generaly sealed by pouring concrete board or mortar.

- Q:What are the commonly used admixture for alumina-magnesia refractory? What are the impacts on its performance?

- Sodium silicate, pure calcium aluminate cement, boric acid

- Q:who knows the fire endurance of fireproof coating?

- this is not specfied , depending on design requirements. The products we made have fire endurance from 1to 4hours . We have not done any higher.how is the fireproof coating in improving fire resistance of building components? finishing fireproof coating; wood fireproof coating; fire-resistant coating for steel structure, fire-resistant coating for concrete structures, tunnel fire retardant paint, fire retardant paint for the cable. Fire retardant coating is composed of the base materials (that is film forming substance), pigments, ordinary coating additives, fire retardant agent and dispersion medium. In addition to fire retardant agent, other components functions the same as in ordinary coating, but its performance and thickness are specifically required.

- Q:Who can introduce the external wall thermal insulation materials fire rating regulations?

- According to public fire-fighting [2007] No. 182, the contents of the notification on the implementation of a number of issues of national standards GB8624-2006 "building materials and products combustion performance classification", since there is large differences between the new version of the standard GB8624-2006 and the old version of GB8624-1997 in the principle, hierarchical structure and test methods. According to the cintent of notification, in order to ensure a smooth transition between the old and new standards, the current national standard "Fireproof? Specification of Building Interior Decoration?Design" GB50222, "fire?safety?rules of tall civil buildings design" GB50045, "Fireproof? Specification of Building Design" GB50016 have not completed the relevant amendments, the new classification method of GB8624-1997 and GB8624-2006 can be used for temporary reference in terms of combustion performance of materials . From GB8624-2006 standard implementation, the classification of combustion performance is too granular, which do not match to the actual construction of the current project in our country. Therefore, the relevant departments carry on the 3rd amendment for the GB8624-2006 standards, namely GB8624-2012, and it will be released on December 31, 2012 and implemented on October 1, 2013. The combustion grading requirements in the standard: Level A is non-combustible materials (products); level B1 is nonflammable material (products); level B2 is combustible materials (products); level B3 is flammable materials (products).

- Q:what is the fireproofing material of engine room? who knows it ?

- machine room fireproofing materials include: Inorganic binder: The main material includes sodium silicate, gypsum, phosphates, cement,ect.; refractory mineral filler: aluminium oxide, asbestos powder, calcium carbonate, perlite, cornstarch, ect.; nonflammable organic resin: it mainly includes polyvinyl chloride, perchloro-ethylene, chlorinated rubber, neoprene latex, epoxy resin, phenol resin, ect.. nonflammable fireproof addictive: it mainly has phosphorus, halogens, nitrogen organic compounds (chlorinated paraffins, tributyl phosphate,deca-brominated diphenyl ether), and boron series (boric acid, zinc borate, aluminium borate), antimony system, aluminium series, zirconium system, etc. inorganic compounds.

- Q:What are the refractories for converter?

- Permanent layer (sintering) magnesia brick, the working lining gunning material for the working layer and the permanent layer gap, using magnesia ramming materials, MgO-C brick brick supply,

- Q:How to make the service life of refractory materials longer?

- Take acid resistant refractory materials as example: the atmosphere should be acidic atmosphere, if used in an environment whose temperature is 1900℃, it would exacerbate the loss of refractory materials, so don’t use overloaded. Second, select the appropriate refractory materials according to the environment. For example, if its operating temperature is 1800℃, generally speaking, the normal use of it according to the instruction of refractory materials would be fine.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

white fused alumina for refractory 99.2%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords