White Felt Surface PVC Conveyor Belt for Food Bakery Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Felt Surface PVC Conveyor Belt for Food Bakery Industry

Conveyor Belt Description:

Color White

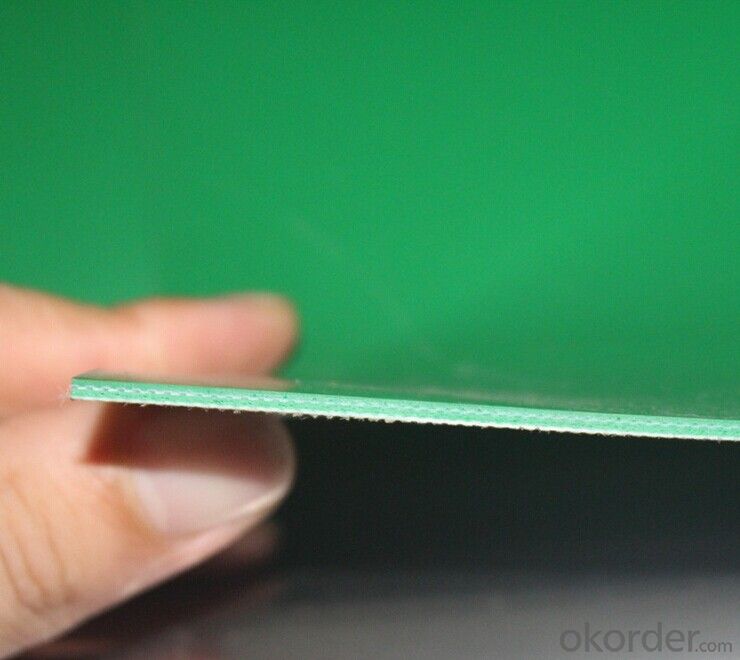

Fiber layers 2 plies

Fiber class Lateral stability polyester fabric

Surface material Wool felt

Surface pattern --

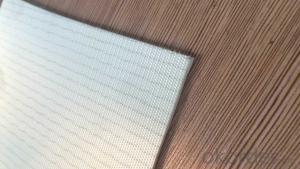

Bottom material Polyester fabric

Total thickness 3.0mm

Surface coated thickness 1.0mm

Weight 2.9kg/sqm

Maximum width 2200mm

Elongation 1% force 10N/mm

Hardness shoreA --

Working temperature -10~+80℃

Minimum pulley diameter 80mm

Conveyor Belt Feature

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Conveyor Belt Applications

Food bakery industry.

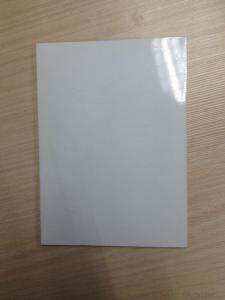

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How does an olive net affect the overall fruit texture in the olive grove?

- An olive net can have a significant impact on the overall fruit texture in an olive grove. By placing the net underneath the olive trees, it helps to catch the falling olives, preventing them from hitting the ground. This prevents any potential damage or bruising to the fruit, ensuring that it maintains its optimal texture. Additionally, the netting creates a barrier that prevents the olives from coming into contact with the soil, reducing the risk of contamination and maintaining the fruit's quality. Overall, an olive net plays a crucial role in preserving the fruit's texture and ensuring a higher quality yield.

- Q:Are there any specific techniques for maintaining soil fertility when using olive nets?

- Yes, there are specific techniques for maintaining soil fertility when using olive nets. One effective technique is to regularly monitor and adjust the irrigation schedule to ensure that the soil receives adequate moisture without becoming waterlogged. Additionally, using organic fertilizers or compost can help replenish nutrients in the soil. It is also important to remove fallen leaves and debris from the nets to prevent them from decomposing on the soil surface and depleting its nutrients. Finally, rotating the location of the nets each year can help minimize soil compaction and promote healthy soil structure and fertility.

- Q:Can olive nets be used for olive tree rejuvenation?

- No, olive nets cannot be used for olive tree rejuvenation. Olive nets are primarily used for harvesting olives by preventing them from falling to the ground, but they do not have any rejuvenating properties for the trees themselves. Olive tree rejuvenation typically involves pruning, fertilizing, and other horticultural practices to promote new growth and increase productivity.

- Q:Do olive nets also protect against other pests?

- No, olive nets primarily protect against birds and insects that are attracted to olive trees. They are not designed to protect against other types of pests.

- Q:How do you determine the optimal time to install olive nets for harvesting?

- The optimal time to install olive nets for harvesting can be determined by assessing the maturity level of the olives. This can be done by regularly monitoring their color and size. When the olives start to turn from green to a darker shade, indicating ripeness, and reach the desired size, it is an indication that the harvest season is approaching. Additionally, checking the weather conditions and considering factors like wind and rain can help determine the best time to install the nets, ensuring efficient harvesting and minimal damage to the olives.

- Q:Can olive nets be used in combination with irrigation systems?

- Yes, olive nets can be used in combination with irrigation systems. The nets are primarily used for collecting olives during harvest, but they do not interfere with the operation of irrigation systems.

- Q:Can olive nets be used for olive trees in regions with limited water availability?

- Yes, olive nets can be used for olive trees in regions with limited water availability. Using olive nets can help conserve water by reducing evaporation and preventing excessive drying of the soil. Additionally, the nets can provide shade and reduce direct sunlight exposure, which can further help in conserving water by reducing transpiration rates of the olive trees.

- Q:Are there any specific techniques for preventing olive net damage from strong winds?

- Yes, there are several techniques for preventing olive net damage from strong winds. One effective technique is to use a double-layered netting system, where two layers of nets are used with a small gap in between. This helps to reduce wind resistance and minimize the chances of the netting getting torn or damaged. Additionally, securing the nets tightly to the ground using heavy-duty stakes or weights can provide extra stability and prevent them from getting blown away. Finally, regularly inspecting and maintaining the nets, repairing any damages or weak spots promptly, can help prevent further damage during strong winds.

- Q:Can olive nets be used for olive tree temperature regulation?

- No, olive nets are primarily used for protecting the olives from birds and other pests, not for temperature regulation of the olive tree.

- Q:How do olive nets prevent fruit bruising during harvesting?

- Olive nets prevent fruit bruising during harvesting by providing a protective barrier between the olives and the ground. When the olives fall onto the nets, they are cushioned and prevented from hitting the hard surface, which minimizes the risk of bruising. The nets also make it easier to collect the olives without causing any damage to the fruits.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Felt Surface PVC Conveyor Belt for Food Bakery Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords