White Extruded Polystyrene board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

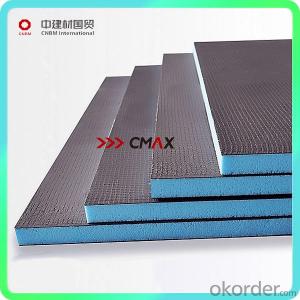

| Type: | XPS Boards | Place of Origin: | China (Mainland) | Brand Name: | |

| Model Number: | TYXPS | Color: | pink or blue | Compressive strength: | >250Kpa |

| Apparent Density: | 35~40kg/m3 | Heat Conductivity: | 0.027~0.030 | Highest Working Temperature: | 75 centidegree |

| Water absorption: | <=1.00% | Coefficient of linear thermal expansion: | 0.07 |

Packaging & Delivery

| Packaging Detail: | plastic bag |

| Delivery Detail: | 7 days after deposit |

Specifications

White extruded polystyrene board

1. HCFC and CFC free

2. Length<=6000mm

3. Thickness:4~120mm

4. CE approved

White extruded polystyrene board (CE)

Product Description

XPS foam board is an extruded polystyrene insulation manufactured through a plastic extrusion process. The resulting boards are almost 100% closed cell, strong, highly moisture resistant and easy to cut and shape.

XPS foam board widely used in wall insulation, low-temperature storage facilities, parking platform, the airport runway, construction of concrete roof and the structure of the roof, highways and other areas of moisture-proof inexpensive decoration industry Material.

Characteristics:

Stable performance and anti-aging: The extruded polystyrene (XPS) insulation boards can be used 35-50 years.

Resistance to compression: compared with other thermal insulation material(200Kpa for EPS), it has better compressive strength(around 300Kpa), which make it the ideal solution for heavy domestic or industrial loads

Water resistance: Polyfoam is almost 100% closed cell and as such is unaffected by moisture

Lightweight: volume optimization and easy to handle

Resistance to deformation

Resistance to impact

Versatile: the closed cell structure and density of Polyfoam allow specific edge details and surface finishes to be cut into the boards to make them as fit for the job as possible. Moreover, Polyfoam can be cut into almost any shape.

Recyclable: Polyfoam can be 100% recycled

Available Sizes:

Length | Width | thickness |

no limitation could be cut according to design | 600mm 900mm 1200mm | 20~100mm |

Other thickness as 4mm~10mm, could be cut from thicker panel

Technical Data:

Density | Kg/m3 | 35~45 |

Thermal conductivity, 90 days, 10°C | W/mK | 0.027~0.036 |

Compressive strength at 10% deflection or yield, (vertical) | kPa | 250~700 |

Tensile strength | kPa | ≥350 |

Water absorption | Vol-% | <=1.00% |

Capillarity | nil | nil |

Coefficient of linear thermal expansion | mm/mK | 0.07 |

Temperature limits | °C | -50°C, +75°C |

- Q:What is the difference between an extruded board and an XPS extruded board?

- Foam plastic plate insulation effect, hinder the outdoor temperature affect the indoor temperature, can play the role of Dongnuanxialiang. . the snow has the role of heat insulation, isolated 礌 礌 礌 蕺 蕺 蕺 蕺 scrapped wheat and outside the air contact, on the one hand to prevent the wheat freeze and death, on the other hand have the effect of refrigeration . to the thicker glass When the water is turned down, the inner glass is exposed to rapid heat, and the outer glass is in contact with the cold air of the cup, so that the expansion of the inner and outer walls causes the difference.

- Q:How to distinguish between good and bad insulation board insulation board

- Your main source of high temperature in the room is the west of the glass and the south of the window you can in the west and south from the glass 20_50 cm hanging curtains so much of the heat was blocked the roof available 60 * 60 gypsum board ceiling that Economic effect and good ceiling 15-18 yuan per square

- Q:Roof insulation layer is extruded polystyrene foam plate how set the amount of set

- The honeycomb structure of the thick plate, there is no gap, this closed-cell structure Insulation materials can have different pressures (150-500Kpa) at the same time have the same low value of the thermal conductivity (only 0.028W / MK) and enduring excellent insulation and compression performance, compressive strength up to 220-500Kpa.

- Q:Roofing the top of the extruded polystyrene insulation board generally how much weight ah?

- Metal hose is an important connection in engineering technology, from the corrugated flexible tube, mesh sets and joints combined. China in 1993 issued a national standard "corrugated metal hose general technical conditions" (GB / T-93). Metal hoses are made of austenitic stainless steel or according to the material required by the user. It has excellent softness, corrosion resistance, high temperature resistance (-235 ℃ ~ + 450 ℃), High pressure (up to 32MPa), in the pipeline can be connected in any direction for temperature compensation and absorption of vibration, reduce noise, change the direction of media transmission, to eliminate the pipe or between the pipe and mechanical displacement between equipment, Lan metal corrugated hose for a displacement, vibration of the various pumps, valves and other flexible joints is particularly applicable. Metal hoses use two kinds of bellows, one is a spiral corrugated tube; the other is a ring bellows. Spiral bellows The spiral bellows is a tubular shell with a corrugated spiral and has a helix angle between adjacent two corrugations. All corrugations can be connected by a helix. Ring bellows Corrugated tube is corrugated closed ring shaped tubular shell, wave and wave from the ring ripple in series. The ring bellows is machined from a seamless pipe or welded pipe. By the processing mode, compared with the spiral corrugated pipe, the length of a single tube is usually shorter. The advantage of the ring bellows is good elasticity and small rigidity. If you need to provide detailed advice, please call 0317-, Xinlong bellows will be happy to serve you.

- Q:I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- 25 thick extruded polystyrene plastic insulation board 35kg / m3

- Q:What is the difference between extruded polystyrene board and XPS insulation board?

- Brothers asked, what is the price of extruded board in 2008 to do a report need to trouble to tell the next thank you

- Q:25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q:Sound insulation and polystyrene insulation board which sound insulation better?

- The best bamboo pole, or plastic, aluminum alloy, then there is no child at home can have a child, then it is dangerous to fall easily hit people

- Q:Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Building safety production management issues, please choose the answer (multiple choice)

- Q:Why extruded board (XPS board) is the best insulation board material

- Should belong to the template and support system. Full scaffolding is generally used for single-storey building, hall and other high-rise, large building between the top of the building decoration. By the pole, cross bar, bracing, scissors and other components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Extruded Polystyrene board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords