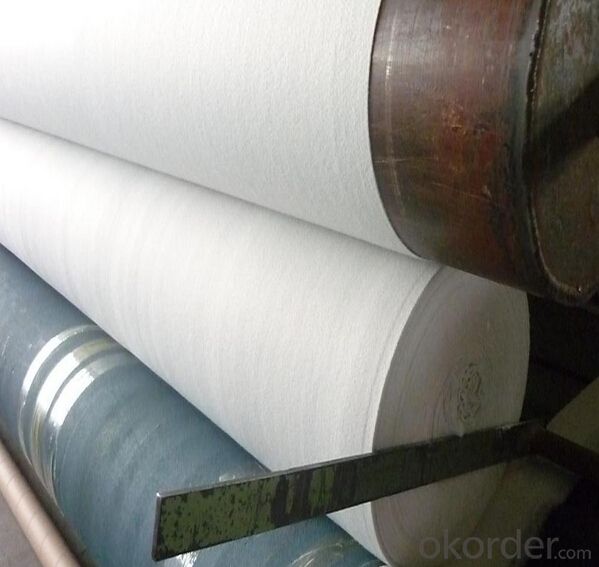

White Color PET Polyester Geotextile Filter Fabric Price

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White Color PET Polyester Geotextile Filter Fabric Price

Desciriptions:

Geotextile can avoid the sharps objects damage to pipeline and others buried underground.

Geotextile can reinforce the roadbed,slow down the pavement fracture.

Specifications:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Wide-width rolls

Quality Certified

Proven for use in Main Roads works

Large range to suit the application

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

♦ Packing:in plastic film bag(keep away from moisture) and PP bag or as your customize.

♦ Shipping:By sea or as your customize

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

HDPE Geomembrane Price

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:Geotextile manufacturers rely on what to do a hundred years do not rot geotextile

- Because geotextile raw materials are chemical fiber. Huazhi geotextile material answer

- Q:Geotextile seam construction how to do

- Sewing of geotextiles All sutures must be carried out continuously (for example, spotting is not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). The seam of the geotextile seam is covered by a single line of thread lock. The line used for suturing should be a resin material with a minimum tension of more than 60N and is resistant to chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation. Cloth lap according to the terrain and the use of functions can be divided into natural lap, seam or welding. Geotextile manufacturers, for your answer

- Q:How are geotextiles tested for durability?

- Geotextiles are tested for durability through various methods, including exposure to environmental factors such as sunlight, moisture, and temperature changes. Additionally, they undergo mechanical tests like puncture resistance, tear strength, and tensile strength evaluations. These tests help determine the geotextile's ability to withstand long-term use and maintain its structural integrity in different applications.

- Q:Do you have a geotextile bed?

- Well, geotextile material is not environmentally friendly

- Q:What are the different geotextile tensile strength test methods?

- Some of the different geotextile tensile strength test methods include the grab test, strip test, wide-width strip test, and trapezoidal tear test. These methods are used to measure the resistance of geotextiles to pulling forces and provide valuable information about their overall strength and durability.

- Q:Geotextile price, the number of square feet per square

- You have different specifications and different prices. The number of square feet per ton to see how much you do grams, the greater the weight, the less the square number. Huazhi geotextile material manufacturers to answer.

- Q:What are the key differences between woven and nonwoven geotextiles?

- Woven geotextiles are made by weaving individual threads together to create a strong and durable fabric, while nonwoven geotextiles are made by bonding fibers together using heat, chemicals, or mechanical processes. Woven geotextiles have high tensile strength and are commonly used for soil stabilization, erosion control, and separation of different soil layers. On the other hand, nonwoven geotextiles have excellent filtration and drainage properties, making them suitable for applications such as filtration, separation, and protection. Overall, the key differences between woven and nonwoven geotextiles lie in their manufacturing process, physical properties, and intended usage.

- Q:How do geotextiles affect soil erosion rates?

- Geotextiles can significantly reduce soil erosion rates by acting as a barrier against erosive forces such as water flow or wind. They provide stabilization and reinforcement to the soil, preventing it from being easily displaced or washed away. By enhancing the soil's resistance to erosion and promoting vegetation growth, geotextiles help maintain soil integrity and reduce erosion rates.

- Q:What are the different geotextile filtration testing methods?

- Some of the different geotextile filtration testing methods include the gradient ratio test, the permittivity test, the sieve analysis test, the flow rate test, and the hydraulic conductivity test. These methods are used to determine the effectiveness of geotextiles in filtering water and preventing soil erosion.

- Q:Are geotextiles commonly used in sports field applications?

- Yes, geotextiles are commonly used in sports field applications. They are often used to improve drainage, prevent soil erosion, and enhance the stability and durability of the field.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White Color PET Polyester Geotextile Filter Fabric Price

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords