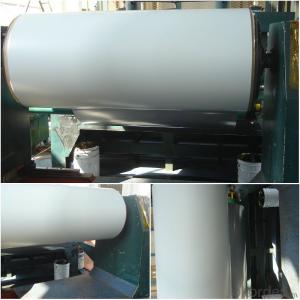

White color PE coated aluminum roofing sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Aluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q:if air goes throught a lot of tiny aluminum will cause cooling? Why am i asking this because when you see inside the computer desktop has heatsink fan, and some of the heatsink are made by aluminum.

- Sorry, but copper is just the opposite of aluminum. It soaks up heat like a sponge and doesn't dissipate it quickly. Try heating a piece of copper tubing and see how long it takes before you can touch it.

- Q:Can aluminum coils be used in solar panel systems?

- Solar panel systems can indeed utilize aluminum coils. Aluminum is commonly selected as the material for frames and supports in solar panels because of its favorable combination of lightness and strength. Its resistance to corrosion, durability, and impressive thermal conductivity make it an ideal choice for enduring severe weather conditions and efficiently dispersing heat generated by the panels. Furthermore, aluminum is highly recyclable, which aligns perfectly with the environmentally conscious nature of solar energy systems. In conclusion, incorporating aluminum coils into solar panel systems enhances their efficiency, lifespan, and eco-friendliness.

- Q:How do aluminum coils compare to other types of coils (e.g., copper)?

- Aluminum coils generally have a lower cost compared to copper coils, making them a more budget-friendly option. However, copper coils tend to have better heat transfer properties and are more durable, which can result in improved system performance and longer lifespan. The choice between aluminum and copper coils depends on factors such as budget, desired efficiency, and specific application requirements.

- Q:Are aluminum coils suitable for electrical grounding applications?

- Yes, aluminum coils are suitable for electrical grounding applications. Aluminum is a highly conductive material, with approximately 61% of the conductivity of copper. It is commonly used in electrical applications where conductivity and corrosion resistance are important factors. Aluminum coils provide a cost-effective alternative to copper coils for grounding purposes. Additionally, aluminum coils are lightweight and easy to work with, making them a popular choice for electrical grounding applications. However, it is important to ensure proper installation and maintenance to prevent any potential issues like galvanic corrosion when connecting aluminum to other metals.

- Q:I am so confused right know. I want to cook something using an aluminium foil. Is the reflective side supposed to be inside or outside?

- it doesn't matter - they are exactly the same the shinier side is a result of the rolling during the manufacturing process and makes no difference whatsoever

- Q:How do aluminum coils contribute to sustainable and green building practices?

- Aluminum coils play a crucial role in sustainable and green building practices due to their numerous environmental benefits. Here's how aluminum coils contribute to these practices: 1. Energy efficiency: Aluminum coils are lightweight and have excellent thermal conductivity, making them ideal for insulation purposes. When used as a part of the building's envelope, aluminum coils help reduce heat transfer, resulting in increased energy efficiency. This, in turn, reduces the need for excessive heating or cooling, leading to lower energy consumption and greenhouse gas emissions. 2. Longevity and durability: Aluminum is highly resistant to corrosion and has a longer lifespan compared to other materials. This durability reduces the need for frequent replacements, which can have a significant environmental impact. By using aluminum coils in construction, we can reduce waste and conserve resources. 3. Recyclability: Aluminum is one of the most recyclable materials available, with a high recycling rate. When aluminum coils reach the end of their life cycle, they can be easily recycled and turned into new products without any loss in quality. By choosing aluminum coils, we support a closed-loop recycling system, reducing the demand for virgin materials and minimizing waste. 4. Reduced carbon footprint: Aluminum production requires significantly less energy compared to other metals like steel or copper. This lower energy consumption results in a reduced carbon footprint during the manufacturing process. Additionally, using recycled aluminum in coil production requires even less energy, making it an even more sustainable choice. 5. Reflectivity: Aluminum has high reflectivity, allowing it to reflect sunlight and heat away from the building. This property helps reduce cooling loads, especially in hot climates, thereby reducing the energy needed for air conditioning. By incorporating aluminum coils in roofing or cladding, buildings can minimize their impact on local microclimates and reduce the urban heat island effect. Overall, aluminum coils contribute to sustainable and green building practices by promoting energy efficiency, durability, recyclability, and reducing the carbon footprint. By choosing aluminum as a construction material, we can create greener buildings that conserve resources, reduce waste, and minimize environmental impact.

- Q:Dongying power plant with 0.6mm thick insulation aluminum coil, manufacturers can be divided into small volumes?

- Tolerable。 The price depends mainly on what you need to split into.

- Q:How are aluminum coils installed in various applications?

- Aluminum coils are typically installed in various applications by following a few general steps. First, the area where the coil will be installed is prepared by ensuring it is clean and free from any debris. Then, the coil is carefully unrolled or unfolded, depending on its form, and positioned in the desired location. Next, the coil is securely attached or fastened using appropriate methods such as screws, nails, adhesive, or brackets, depending on the specific application. It is important to ensure that the coil is properly aligned and securely fixed to prevent any movement or damage. Finally, any necessary finishing touches, such as sealing or insulating, may be applied to ensure optimal performance and longevity of the aluminum coil in its respective application.

- Q:Can aluminum coils be used for electrical conductivity purposes?

- No, aluminum coils cannot be used for electrical conductivity purposes. While aluminum is a good conductor of electricity, it is not suitable for use in coils specifically designed for electrical conductivity. Aluminum has a relatively high resistance compared to other materials such as copper or silver, which are commonly used for electrical conductivity purposes. Additionally, aluminum has a lower melting point than copper, which can lead to overheating issues when used in coils for high electrical currents. Therefore, it is more common to use materials like copper or silver for electrical conductivity purposes, especially in applications where high conductivity and low resistance are required.

- Q:Why are the aluminum coils sticky after annealing?

- There is oil or the annealing time is too long!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White color PE coated aluminum roofing sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords