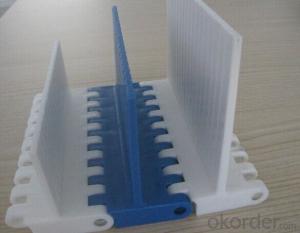

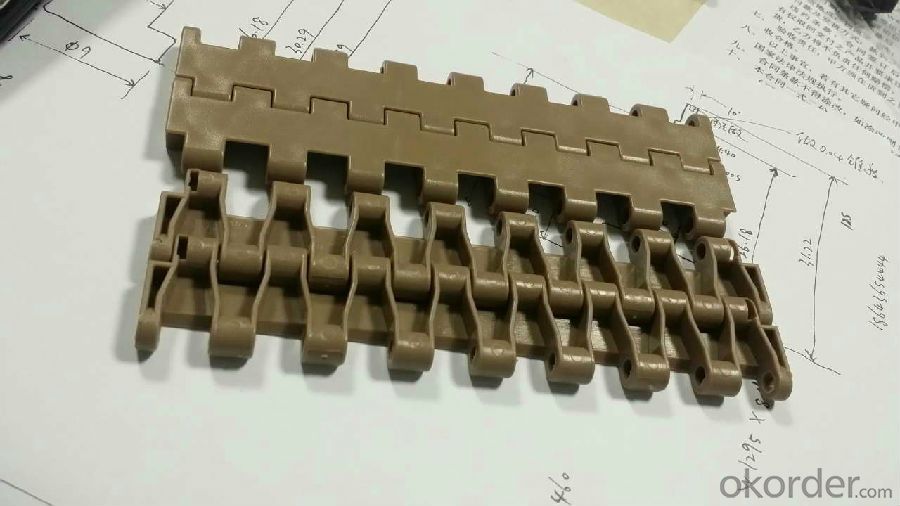

White/Blue/Coffee Color Plastic Modular Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

White/Blue/Coffee Color Plastic Modular Conveyor Belt

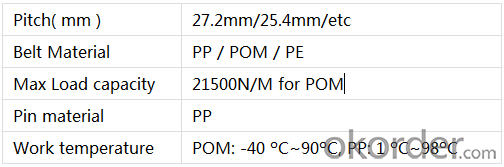

Specification of modular belt

Product Features :

Good performance of anti-stretching, anti-impact, anti-creepage, anti-abrasion, anti-erosion.

Excellent mechanical performance.

Stable chemical property.

Wide range of work temperature.

Low friction on bottom side.

Non-stick of water and oil.

Long service life.

Application of our products:

Our products are widely used in the conveyor of production of light industry as below:

Agriculture: Washing/disinfecting/drying/packing/cooling/freezing of vegetables/

fruit/meat/aquatic products/sea food.

Food: Instant noodles/rice noodles/snacks/box lunch/bakeries/cans/sugar.

Wines and beverage: Mineral water/pure water/soft drink / milk/dairy/wines.

Medicine and chemical industry.

Tobaccos.

Electronics and batteries.

Machinery components/auto parts/powder metallurgy/glass.

Logistics.

Pls contact me freely if any inquiry,thank you!

- Q:Can olive nets be used to promote organic certification?

- Yes, olive nets can be used to promote organic certification. Olive nets are commonly used in organic farming practices to protect the olives from pests and ensure they are not contaminated with synthetic chemicals. By using olive nets, farmers can demonstrate their commitment to organic farming methods, which can help in obtaining organic certification. Additionally, the use of olive nets can help maintain the quality and integrity of the olives, which is essential for meeting the standards required for organic certification.

- Q:Can olive nets be used in areas with heavy snowfall?

- No, olive nets are not suitable for areas with heavy snowfall as they are designed specifically for harvesting olives and may not be able to withstand the weight and pressure of heavy snow.

- Q:Do olive nets impact the size of the olives?

- Yes, olive nets can impact the size of the olives. Olive nets are used to protect olive trees from birds and other animals, reducing the risk of damage or loss. By preventing external factors from affecting the olives, such as bird pecking or wind damage, olive nets can help promote healthier growth and potentially result in larger-sized olives.

- Q:Can olive nets be used on trees with irregular shapes?

- Yes, olive nets can be used on trees with irregular shapes. Olive nets are flexible and can be adjusted to fit the contours of the tree, ensuring proper coverage and protection against birds or other pests.

- Q:Are olive nets reusable for multiple seasons?

- Yes, olive nets are typically reusable for multiple seasons. They are designed to withstand outdoor conditions and can be easily cleaned and stored for future use.

- Q:What is the difference between waste pressure plastic pipe and PVC pipe?

- PVC for a long time has the chlorine ion release, not suitable for tap water pipe, poor impact resistance, not suitable for the gas pipeline, but the PVC low price, high hardness, affected by the temperature rise of heat cold shrink, commonly used in drainage pipeline, water pipeline.

- Q:What are the different colors available in olive nets?

- The different colors available in olive nets can vary, but some common options include green, brown, and black.

- Q:How do olive nets affect the overall oil content of the olives?

- Olive nets have a minimal impact on the overall oil content of the olives. These nets are primarily used to prevent the olives from falling to the ground and getting damaged, rather than directly affecting their oil content. The oil content of olives is mainly influenced by factors such as olive variety, ripeness, and growing conditions, rather than the use of nets.

- Q:How do olive nets help in reducing the risk of fruit drop?

- Olive nets help in reducing the risk of fruit drop by providing a physical barrier that prevents the olives from falling to the ground. This barrier catches the olives as they ripen and fall, preventing damage and minimizing the risk of fruit drop. Additionally, olive nets create a controlled environment for the olives, protecting them from wind, pests, and other external factors that could lead to premature fruit drop.

- Q:Can olive nets be used in hilly or sloping terrains?

- Yes, olive nets can be used in hilly or sloping terrains.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

White/Blue/Coffee Color Plastic Modular Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords