Wellhead Assembly of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Wellhead Assembly Description

The gas production wellhead assembly is designed and manufactured in accordance with GB/T22513-2008 and API Spec 6A standards.All pressure-bearing parts and flanges are forge pieces of high-grade alloy steel and stainless steel and subjected to non-destructive test(NDT) and special heat treatment to insure safety and good sulphur-resisting performance.

This product consists of such components or parts as bottom flange,top flange,tubing head,gate valves,small-sized four-way union,stop valves and measuring instruments,etc.

2. Main Features of Wellhead Assembly

Working Pressure: 2000-20000psi

Working Temperature: PU Material Class: AA-FF

Available Medium: Crude Oil, Water, Gas

Connection Type: Clamp, Flanged

PR: PR1-2

PSL: PSL1-3

Normal Size: Main (in): 2-9/16, 3-1/8, 3-1/16

Side (in): 2-9/16

3. Wellhead Assembly Images

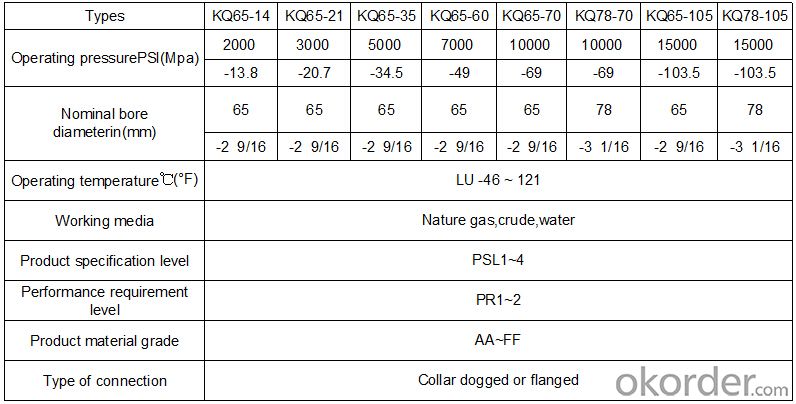

4. Wellhead Assembly Specification

5. FAQ of Wellhead Assembly

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing Oilfield products in China, mainly offering various of oilfild products consists of our one-stop sales. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q:I am trying to replace a leaky valve stem. And I didn't know how to get to the valve core and when I get there how do I change it? The charge is recovered. It is a 2000 Impala. Thanks in advance.Noah

- You say you want to change out the valve stem but can't find the valve core but the charge has been recovered. How did the charge get recovered without knowing where the valve core is. That's where the charge was recovered through. Also, if you have a leaking valve stem how did you still have a charge to recover, it would have leaked out through the leaking valve stem.

- Q:My cardiologist says I have Mitral Valve Relapse. She says MVR is when there is a backflow of bood entering the heart. When I checked online for MVR, I couldn't find anything except MVP (Mitral Valve Prolapse). What is MVR and how is it different than MVP?

- I believe you DO mean MVP. You probably misunderstood your cardiologist. Prolapse is a deformation of the valve in which valve does not completely close, causing a back flow of blood into the atrium. In most cases this is relatively benign and in fact, occurs in about 10% of people. In severe cases, you may need a value replacement, but usually this occurs at birth or after a disease damages the heart.

- Q:hello!I'm designing a floor cleaner and for a water release system i was thinking of using a ball valve, connected to an actuator,however i'm not fully sure what to look for, and although I can buy the actuator and ball valve together, I'm not sure how to connect it to a motor and battery?If anyone can help my with this I'd really appreciate it!!Thank You!!

- it is going to be to long of an answere to bypass by, yet you have a often closed valve and a often open valve. So while air is provided, one opens and the different closes. you may artwork something out with that based how your set up is going to be. it rather is the solenoids i'm talking approximately.

- Q:What would this envole, can i size up/down the port on the existing valve with just changing the mechanical componts.

- On okorder /

- Q:I have a T4-T10 and L5-S1 spinal injury and I recently found out that my tricuspid and my mitral valves leak. I have never had heart problems before I got the spinal injury. Do you think the valve leaks could have been from the trauma when I received the spinal injury?

- I wouldn't think the trauma would directly injure the valves. Were you in the hospital for a long time following that injury hooked up to IVs? With IV catheters there is the possibility of bacteria entering the bloodstream and causing damage to the valves. Maybe that is why you developed valve issues. Also I wonder if there is the possibility that the massive immune and inflammatory response generated by that much trauma to your body may have caused some damage to the valves. I've never heard that happening, but I imagine it's possible. Also it may just be coincedence and you may have had the valve issues before but never had reason to check them out. A small leak in the heart valves is very common as people get older.

- Q:I am having a leaky valve is that normal? the doctor said that it is normal what do i do?

- Slightly Leaky Heart Valve

- Q:If someone is not born with heart valve disease... can a teenager or a 12 year old develop heart valve disease?

- OMG, I can't imagine losing my dad or anyone else I loved at such a young age. But to answer your question, I think it's a lil of both. Or at least it certainly must seem that way right now. My dad is dying from cancer. He's 67 even still, I'm having a hard time with it. What your brother is going thru, is normal, I'm sure knowing that doesn't make it any easier for you. But maybe you could talk to someone like a therapist who could maybe give you some help in dealing with your brother as well as your grief over your dad. After my 2nd sister died, people would often ask how long we thought my mom would grieve. Our response was always, not everyone grieves the same, and death of a loved one is not something we get over. But after awhile, the pain isn't as constant as before each day gets a lil easier. Maybe when school starts you could talk to a school counselor or they could recommend a local one for you. In the meantime, talk to your friends or any family members. They know what you're going thru, they love you they will want to help in whatever way they can. Wish I could hug ya, cuz I know where you've been. Whether your loved one dies from a long suffering disease that you've known of or in a sudden accident, it's a horrible thing to have to go thru.

- Q:I jsut got my valve cover replaced on my car what does that do?

- it keeps the oil from flying out and also keeps dirt out of your engine.

- Q:freak accident broke the shutoff valve at my toilet, so first thing i did was shut the water off at the main shut off valve inside the house. then fixed the toilet shut off valve then went to turn the water back on at the house valve and it ran for a few seconds and that was it. so i then went to the main valve at the street to make sure it was open. it was open as well as all the others inside the house. still no running water. please help.

- did you strip the knob handle?

- Q:I just found out about my condition. Is it dangerous? And will I need surgery? My mom just got her monocuspid valve replaced. I don't wanna have to go through the same thing. And will I still be able to go on rollercoasters? I'm going to cedar point tomorrow. I only want answers from people who know exactly what there talking about thanks

- Yes you might have constantly had this, it is some thing you had been born with. A natural aortic valve is tricuspid, that's it has 3 final flaps, however a bicuspid valve best has 2 flaps. Sometimes those bicuspid valves provide no issues, however in a few individuals they are able to result in center murmur later in lifestyles ( mostly on your 30s or 40s ) in view that they enable somewhat blood to leak again the flawed manner while they're closed. If this will get extreme sufficient, you can also want surgical procedure to suit a man-made valve. This is lovely ordinary at the moment and now not some thing to fear approximately.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wellhead Assembly of High Quality with API 6A Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords