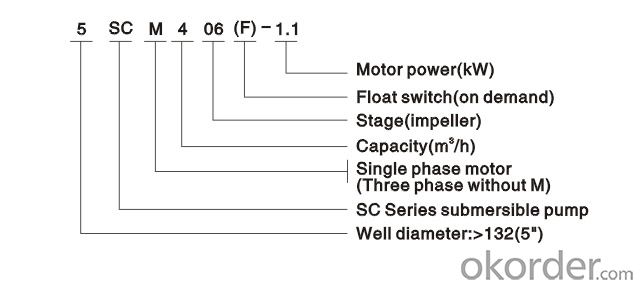

Well Pump 5SC

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

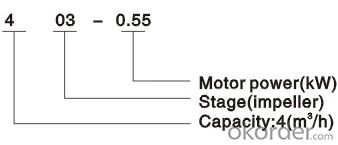

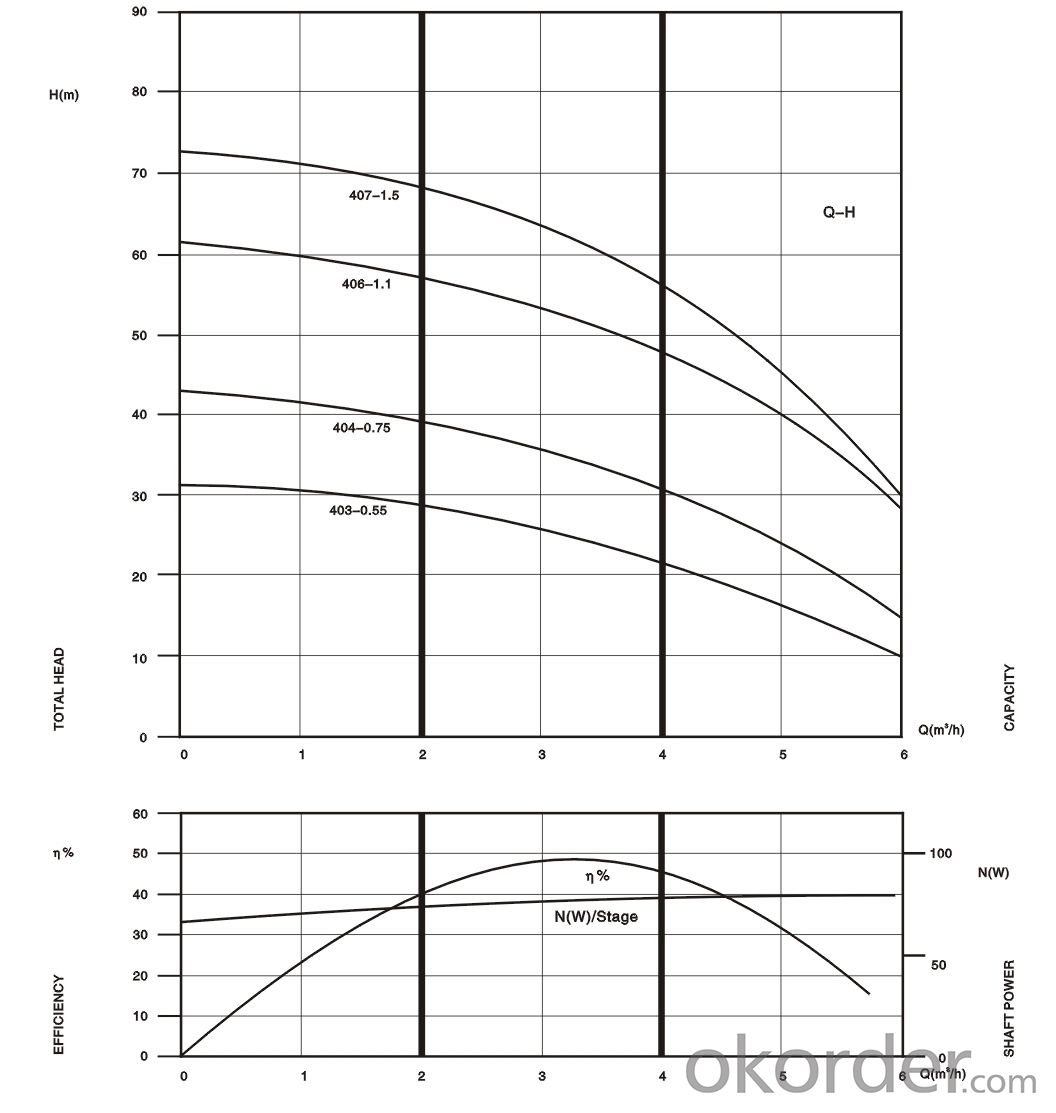

Well Dia.:>132mm(5") -Pump -Motor |  | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q:I am going to replace the timing belt , tesioner and idler bearing on my 2000 daewoo leganza. I noticed some of the kits have water pumps too. It is likely to break like the timing belt?

- I would suggest to replace the car itself.

- Q:I moved into a house on a rural property in January, and we live off tank water and have a Grunfos PT18 pumping all our water into the house.The problem is, not all the time, but alot of the time my pump stays on after having a shower, the motor keeps running and restarting continuously as if it is desperately trying to pump more water through, until I go underneath my house and literally turn it off at the powerpoint, wait for a bit then turn it back on. I am scared if I leave the motor keep going like that it will burn my pump out. Does anyone have any suggestions on how I can fix this problem, or why it may be doing this, or is something causing it?Thankyou in advance, from someone who has next to no knowledge about pumps!!

- Sounds like it's waterlogged. That's what it's called when the water and the air in the resevoir tank mix, and the volume of air gets so small as to not be able to provide any decent compression with which to push water through the system. At that point, any time you open a fixture, the pressure drops enough to turn on the pump, and when you turn off the pump, if it's just right, it will turn off and then back on, then off, then on, back and forth till you shut it off and it can set and stabilize, till you need water again. The solution is to reintroduce a sizeable amount of air back into the top of the tank. If it's an older tank, without a bladder, (identified by the small bulge around the center of the tank and either a blue or rust color), then the best way is to simply drain the tank and restart the system. That way it will trap all the air in the top of the tank and you'll have enough pressurized air to push a gallon or two of water out, before the pump needs to kick on again. If it's the bladder type, with the bulge, then the bladder has blown and you're, in effect, working with a standard resevoir tank now, except that it will have an air valve in the top like a bicycle tire, so you can pressurize it with an air tank. If so, open some fixtures, start pressurizing the top of the tank and blow all the water out of the system. Once it's dry, put about 20 lbs. of pressure in the tank and start up the pump. You should be good to go.

- Q:How do the water pump work please till me water pump mechanism?

- I assume you're asking about a car water pump. Inside of the pump casing is an impeller (a disc or wheel with vanes). The impeller is connected to a shaft that's connected to a pulley wheel driven by the drive belt from another pulley wheel mounted on the engine shaft. The pump, the radiator and the hoses make up a water filled, enclosed system. As the pump rotates when the engine is running, it circulates the water around the system removing heat from the engine and giving up the heat to the atmosphere through the radiator. ....

- Q:does anyone know how to remove the water pump on an 84 corvette its killing me

- The easiest way is from underneath the car . Loosen the nuts on the pulley first then remove the belt and the rest should be easy from there .

- Q:belt removal mercury cruiser water pump?

- The pump bracket pivots that allows the belt to be removed. I've seen a few where the alternator belt is over the top of the water pump belt, so you have to remove it first. Actually a pretty easy job.

- Q:my nissan 1993 maxima SEthe AC is not cold at all this year it ran perfect the year beforecan the water pump pressure really affect the AC?how much should a new water pump cost for my car?

- It okorder Email me through my profile page if you have any more questions. OK, do it yourself instructions... you will need: -at least 2 (12 oz) cans of R-134a refrigerant -hose with piercing stem that attaches to R-134a can and to your low-side service port (never connect to your hi-side service port) -1 can of Super Seal (comes with basic hose...not with psi gauge) -gloves, long sleeves, pants, (you want to keep covered just in case) Directions: 1. Locate low side service port. 2. Turn on vehicle and set a/c to max cool. 3. Attach hose to can of Super Seal..

- Q:89 Dodge van overheats, no water leak, replaced thermostat but still overheats.

- You probably need a new radiator, they become restricted and do not allow enough water to pass through to efficiently cool the engine.

- Q:PROline Dishwasher has Broken down, after a detailed Examination of the appliance we have managed to conclude it is the Water Pump, I'm looking to find a new one to repair it myself but would like to know if any make one would fit, as Finding a PROline Water Pump has proven Great Difficulty, Any Knowledge of the matter would be greatly appreciated, Thank you

- Before you replace the pump, make sure that the hose to the pump is not blocked with food. This is a common problem. You probably have to match pump for pump. Google the part on line, they will mail it to you. OR check the yellow pages for dishwasher parts, they will answer you questions, and usually tell you how to fix it if you buy the part from them.

- Q:Why does the water pump leak?

- The leakage of water pump is caused by many factors:1, the axial movement of the bearings (axial clearance is too large, resulting in static and dynamic ring open. Leak water.2, and automotive cooling liquid is also related to, if the pH of the coolant is large, will corrode the water seal of the surface, resulting in leakage.3, and the user's use is also related, and some users do not properly maintain, add an unclean coolant, resulting in impurities in the coolant. Accumulation in the water seal surface, destroy the water seal torus, forming water leakage.

- Q:I have a pontiac grand am 1996 v6 with a 3.1L 3100 SFI engine. I have a coolant leak and I think it's coming from the water pump. When the car is cool and then turned on, about 4 to 9 minutes into warming up, coolant is hitting a belt and spraying out of the car's front end. When this is happening I see that there is coolant dripping off of the waterpump housing. The coolant started to spray everywhere about 15 seconds before the radiator fan kicked in. Why would this happen when first warming up only? Can a defective thermostat cause this to happen?

- Mating surfaces of water pump slightly expand after warm up closing tighter on gasket in between, so the leak will not be as much. If you leave it, eventually it may get larger and will leak all the time. Change the water pump and/or it's gasket.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Well Pump 5SC

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords