Welded wire mesh-1/4 X 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Welded Wire Mesh

Welded Wire Mesh is made of by high quality galvanized wire, Low carton steel wire, stainless steel wire, iron wire, Galvanized steel wire, PVC coated iron wire in blue, green, yellow and other colors.

Application of Welded Wire Mesh

Galvanized welded wire mesh, PVC coated welded wire mesh for garden, feeding agriculture, fishing, poultry, mine field, lawn cultivation, and profession’s guard, decorate machine protection. Special welded wire mesh, (Heavy)welded wire mesh panel service as fencing mesh for transportation industry, construction a agriculture.

Surface treatment of of Welded Wire Mesh

a. Black (mild steel wire)

b. Electro galvanized, (galvanized before welding, galvanized after welding)

c. Hot dip galvanized, (galvanized before welding, galvanized after welding)

d. Pvc coated welded wire mesh, (black wire mesh then pvc coated, electro gal. then pvc coated, hot dip gal. the pvc coated)

Advantage of Welded Wire Mesh

Our welded wire mesh has strong corrosion-resisting and oxidation-resisting with good quality and rock bottom price.

Packing of Welded Wire Mesh

1. Waterproof paper then PVC shrinking Film

2. PVC shrinking film only

3. Black waterproof paper only

4. Waterproof paper then metal/wooden pallet

5. Plastic film then carton

(Also as your request. )

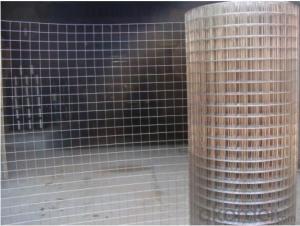

Pictures of Welded Wire Mesh

Specification of Welded Wire Mesh

Standard Welded Wire Mesh (in 30m length, Width of 0.5m-1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

1/4" x 1/4" | 6.4mm x 6.4mm | 22-24 |

3/8" x 3/8" | 10.6mm x 10.6mm | 19-22 |

1/2" x 1/2" | 12.7mm x 12.7mm | 16-23 |

5/8" x 5/8" | 16mm x 16mm | 18-21, |

3/4" x 3/4" | 19.1mm x 19.1mm | 16-21 |

1" x 1/2" | 25.4mm x 12.7mm | 16-21 |

1-1/2" x 1-1/2" | 38mm x 38mm | 14-19 |

1" x 2" | 25.4mm x 50.8mm | 14-16 |

2" x 2" | 50.8mm x 50.8mm | 12-16 |

1/4" x 1/4" | 6.4mm x 6.4mm | 12-16 |

Welded Fencing Mesh (in 30m Length, Width of 0.5m -1.8m) | ||

Mesh | Wire Gauge (BWG) | |

Inch | MM | |

2" x 3" | 50mm x 75mm | 1.65-2.5mm |

3" x 3" | 75mm x 756mm | 1.65-2.75mm |

2" x 4" | 50mm x 100mm | 2.1-2.9mm |

4" x 4" | 100mm x 100mm | 2.0mm,2.5mm |

FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of welded wire mesh and is one of the large-scale professional investment welded wire mesh bases in China. Annually more than 1000 containers of welded wire mesh are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q:How is steel wire mesh used in marine environments?

- Steel wire mesh is commonly used in marine environments for a variety of applications. It is primarily used for reinforcement and protection purposes, such as reinforcing concrete structures like seawalls, piers, and bridges to withstand the corrosive effects of saltwater. Additionally, steel wire mesh is utilized for marine aquaculture, where it acts as cages or nets to contain fish or other marine organisms. Its durability, strength, and resistance to corrosion make steel wire mesh an ideal choice for marine environments.

- Q:Can steel wire mesh be used in electrical applications?

- Yes, steel wire mesh can be used in electrical applications. It is commonly used for grounding purposes, providing protection against electromagnetic interference, and as a conductor in various electrical circuits.

- Q:What are the different roll sizes available for steel wire mesh?

- The roll sizes available for steel wire mesh can vary depending on the specific application and manufacturer. Common roll sizes for steel wire mesh range from 4 feet to 5 feet in width and can have varying lengths, typically ranging from 50 to 100 feet. However, it is important to note that custom sizes may also be available depending on the supplier.

- Q:How does steel wire mesh perform in high-humidity environments?

- Steel wire mesh performs well in high-humidity environments due to its inherent properties and durability. Steel is known for its resistance to corrosion, making it a suitable material for applications in wet and humid conditions. The wire mesh is typically galvanized or coated with a protective layer, further enhancing its resistance to moisture and preventing rusting. In high-humidity environments, steel wire mesh maintains its structural integrity and strength. It does not warp, deform, or lose its shape, ensuring consistent performance over time. The mesh's open design allows for proper ventilation and airflow, preventing the accumulation of moisture that could lead to condensation or mold growth. Moreover, steel wire mesh is commonly used in various industries, including construction, agriculture, and manufacturing, where it is exposed to high humidity levels. It is often employed in concrete reinforcement, fencing, animal enclosures, and filtration systems, among other applications. While steel wire mesh is generally resilient in high-humidity environments, it is essential to select the appropriate grade and coating to suit the specific conditions. This ensures optimal performance and prolongs the lifespan of the mesh. Regular maintenance and cleaning should also be conducted to remove any accumulated debris or moisture, further preserving its functionality and appearance.

- Q:Can steel wire mesh be used for food processing?

- Yes, steel wire mesh can be used for food processing. Steel wire mesh is a durable and versatile material that can be easily cleaned and sanitized, making it suitable for use in various food processing applications. It is commonly used for sieving, filtering, and straining purposes in industries such as baking, brewing, dairy, and meat processing. The small openings in the mesh allow for efficient separation of solids from liquids or for the removal of impurities. Additionally, steel wire mesh can withstand high temperatures and is resistant to corrosion, making it a reliable choice for food processing environments. However, it is important to ensure that the steel wire mesh used for food processing meets food safety regulations and is made from stainless steel or other food-grade materials to prevent any contamination risks.

- Q:Can steel wire mesh be used for window guards?

- Yes, steel wire mesh can be used for window guards. Steel wire mesh is a strong and durable material that can provide effective protection against intruders while allowing for proper ventilation and visibility. It is commonly used for securing windows and preventing unauthorized access to a building or property. The mesh design prevents individuals from entering through the window while still allowing natural light to enter the room. Additionally, steel wire mesh is resistant to corrosion, making it suitable for outdoor applications. Overall, steel wire mesh is a reliable and cost-effective solution for window guards.

- Q:Can steel wire mesh be used for agricultural purposes?

- Yes, steel wire mesh can be used for agricultural purposes. It is commonly used for fencing, animal enclosures, and protecting crops from pests. The mesh provides strength, durability, and good airflow while preventing animals and insects from entering the agricultural area.

- Q:What are the different load-bearing capacities available for steel wire mesh?

- The load-bearing capacity of steel wire mesh can vary depending on several factors such as the thickness and diameter of the wire, the spacing between the wires, and the overall size and configuration of the mesh. Steel wire mesh is commonly available in different load-bearing capacities to suit various applications and requirements. For lighter applications, such as fencing or decorative purposes, steel wire mesh with lower load-bearing capacities may be sufficient. These meshes typically have thinner wires and wider spacing between them, allowing for easier installation and offering a lighter weight solution. In contrast, heavy-duty applications, such as industrial or construction projects, may require steel wire mesh with higher load-bearing capacities. These meshes are usually made with thicker wires and narrower spacing between them, providing increased strength and stability to withstand heavier loads and stresses. Load-bearing capacities for steel wire mesh can range from a few hundred pounds per square foot to several thousand pounds per square foot. It is important to consider the specific requirements of the project and consult with manufacturers or suppliers to determine the most suitable load-bearing capacity for the intended application. Additionally, it is worth noting that load-bearing capacities can also be influenced by the type of steel used, the manufacturing process, and any additional treatments or coatings applied to the mesh. Therefore, it is advisable to obtain detailed technical specifications and performance data from the manufacturer to ensure the chosen steel wire mesh meets the desired load-bearing requirements.

- Q:What are the different temperature resistance options available for steel wire mesh?

- The temperature resistance options for steel wire mesh vary, depending on the specific requirements of the application. 1. Standard Temperature Resistance: Typically, standard steel wire mesh can withstand temperatures ranging from -20°C to 400°C (-4°F to 752°F). This temperature range is suitable for most general applications without extreme temperature concerns. 2. High-Temperature Resistance: If higher temperature resistance is needed, specialized options are available. These meshes, made from heat-resistant alloys like stainless steel or nickel-based alloys, can handle temperatures up to 800°C (1472°F) or even higher. 3. Low-Temperature Resistance: For applications in extremely low temperatures, such as cryogenic environments or cold storage facilities, low-temperature resistant meshes are necessary. These meshes remain flexible and durable at temperatures as low as -200°C (-328°F). 4. Heat Insulation: By combining steel wire mesh with insulating materials, a heat-resistant insulation mesh can be created. This type of mesh is commonly used in applications where heat insulation and protection are crucial, like furnace linings or thermal shields. The insulation material minimizes heat transfer and enhances the overall temperature resistance of the mesh. It's important to note that the temperature resistance of steel wire mesh depends on factors such as wire diameter, weave pattern, and the specific alloy used. Therefore, consulting with a manufacturer or supplier is recommended to determine the most suitable temperature resistance option for a particular application.

- Q:How does steel wire mesh perform in anti-vandal applications?

- Due to its strength and durability, steel wire mesh is an excellent option for anti-vandal applications. When employed in such scenarios, it acts as a robust physical barrier that is resistant to damage and tampering, effectively preventing unauthorized access to restricted areas like construction sites, public spaces, or private properties. One of the primary benefits of using steel wire mesh in anti-vandal applications lies in its ability to withstand forceful impact. The tightly woven design of the mesh ensures its integrity even under significant pressure or attempts to cut or break it. This renders it highly resistant to acts of vandalism and intrusion, providing a reliable and secure barrier. Furthermore, steel wire mesh exhibits resistance to corrosion and rust, making it suitable for outdoor use. It can endure exposure to harsh weather conditions, guaranteeing its longevity and effectiveness in anti-vandal applications. Moreover, steel wire mesh is versatile and can be customized to meet specific anti-vandal requirements. It is available in various sizes, thicknesses, and configurations, enabling tailoring to the precise needs of the application. This adaptability makes it suitable for a wide range of anti-vandal uses, such as fencing, window protection, or equipment security. In conclusion, steel wire mesh is an incredibly dependable and effective option for anti-vandal applications. Its strength, durability, and resistance to damage make it an excellent choice for preventing unauthorized access and deterring acts of vandalism.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Welded wire mesh-1/4 X 1/4

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 5000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords